How to Select a Reliable Drone Battery Supplier from China in 2025?

Want to efficiently select a suitable, reliable, high-quality, and cost-effective drone battery supplier from China, a major power in battery technology?

ENOV High-Energy drone batteries power industrial and commercial drones. Delivering 220–320 Wh/kg energy density, they enable long flight times (30+ mins) and support fast charging (2C). Perfect for aerial photography, surveillance, and delivery drones.

Follow these six key steps to complete the entire process from extensive screening to bulk supplier lock-in, and reduce trial-and-error costs.

Step 1: Match Product Requirements

Clarify the required battery specifications, chargers, compatibility, and differentiated needs to define the supplier profile.

Step 2: Evaluate Product Quality

Obtain on-site videos and images of the supplier’s factory environment, product test reports, industry standard certifications, necessary certifications for the importing country, brand reputation, and customer reviews.

Step 3: Assess Production Capacity

Verify whether the supplier’s production capacity meets requirements, whether its raw material sources are stable, and whether it can meet customization needs.

Step 4: Evaluate Communication Efficiency

Assess the difficulty of language communication with the supplier, cultural alignment, real-time response speed, and after-sales support guarantees during interactions.

Step 5: Analyze Cost Considerations

Understand the supplier’s pricing strategy and cooperation models, and analyze cost-effectiveness. Do not overlook hidden costs such as transportation insurance and tariffs.

Step 6: Lock in via Trial Production

Implement a three-stage process: small batch (sample order) → medium trial (500-1000 units) → bulk order.

Step 1: Match Product Requirements

Whether searching for suppliers on Google independent websites, third-party shopping platforms, or social media, the first focus is undoubtedly whether the factory offers the products you need. Only when the product is available or the factory can produce it does the next step—specific evaluation of the factory’s products—begin. Therefore, you must first clarify your own product requirements to define the supplier profile.

1.Battery Specifications

Common drone battery parameters include voltage, capacity, continuous discharge rate, peak discharge rate, weight, and size.

① Voltage (number of cells, S):

Low voltage (4S-6S) is suitable for lightweight aerial photography drones and racing drones, offering high burst power and strong maneuverability.

High voltage (6S-16S) is suitable for industrial-grade agricultural drones, enabling heavy loads and long operating hours.

② Capacity: Capacity is positively correlated with endurance and negatively correlated with weight.

③ Continuous discharge rate (C): Continuous discharge rate × capacity = maximum continuous current. However, batteries with a higher continuous discharge rate are also heavier, more costly, and have a shorter cycle life.

④ Peak discharge rate (peak C): Determines the drone’s ability to meet sudden demands such as rapid acceleration, climbing, and wind resistance. Exceeding the peak discharge rate may trigger the battery’s power-off protection, leading to drone loss of control.

⑤ Weight: Affects the drone’s climbing speed and load capacity.

⑥ Size: Relates to compatibility with the drone’s battery compartment.

Therefore, parameter synergy determines drone performance:

✅ Power scenarios: High voltage (6S+) + high rate (100C+) → racing/stunt flying

✅ Long endurance scenarios: Large capacity (10,000mAh+) + moderate rate (30C) → aerial photography/mapping

✅ Heavy load scenarios: High voltage (12S) + large capacity (20,000mAh) → agricultural 植保 /logistics

2.Charger Matching

① Voltage consistency: The charger’s output voltage must strictly match the battery’s nominal voltage. Mismatched voltages may cause overcharging or undercharging.

② Power/current compliance: Current = capacity × charging rate (C). For example, A 5000mAh battery requires 5A current for 1C charging and 10A for 2C fast charging.

③ Plug compatibility: Plugs such as XT60 and EC5 must match the charger plug.

④ Protocol support: Communication with the flight controller via CAN bus or dedicated protocols.

⑤ Environmental safety: The charger must be compatible with grid voltages (e.g., 220V single-phase or 380V three-phase), feature BMS six-fold protection, and have good heat dissipation.

3. Compatibility

Compatibility includes: voltage with motor/ESC, discharge rate with power demand, capacity with endurance/weight, physical interface, communication protocol, and brand/system (e.g., DJI drones only compatible with original batteries; third-party batteries may trigger system locking).

4. Differentiated Needs

Buyers from different regions, countries, and industries face varying geographical, living, and application environments, leading to differentiated needs. For example, countries with year-round low temperatures have special requirements for the battery’s low-temperature performance.

Step 2: Evaluate Product Quality

1. Obtain On-site Videos and Images of the Supplier’s Factory Environment

On-site videos or images of the factory are often available on the factory’s official website or social media platforms. What effective information can be derived from these?

① Production equipment and technical capabilities: The factory’s equipment and automation level reflect its technical proficiency. If materials show the complete process from raw material processing to finished product inspection, you can also evaluate its industrial standardization and efficiency. For example, enovbattery has achieved a semi-automated process for cell manufacturing, with only a small number of workers monitoring machines in cleanrooms.

② Environmental and safety management: Whether materials are neatly stacked and the environment is clean reflects the factory’s 5S management level.

③ Operational standardization: Whether workers wear protective equipment and whether processes are standardized.

④ Quality management: If videos/images show raw material inspection and finished product sampling, you can judge whether quality control is in place.

The following picture is a direct shot of Enovbattery.

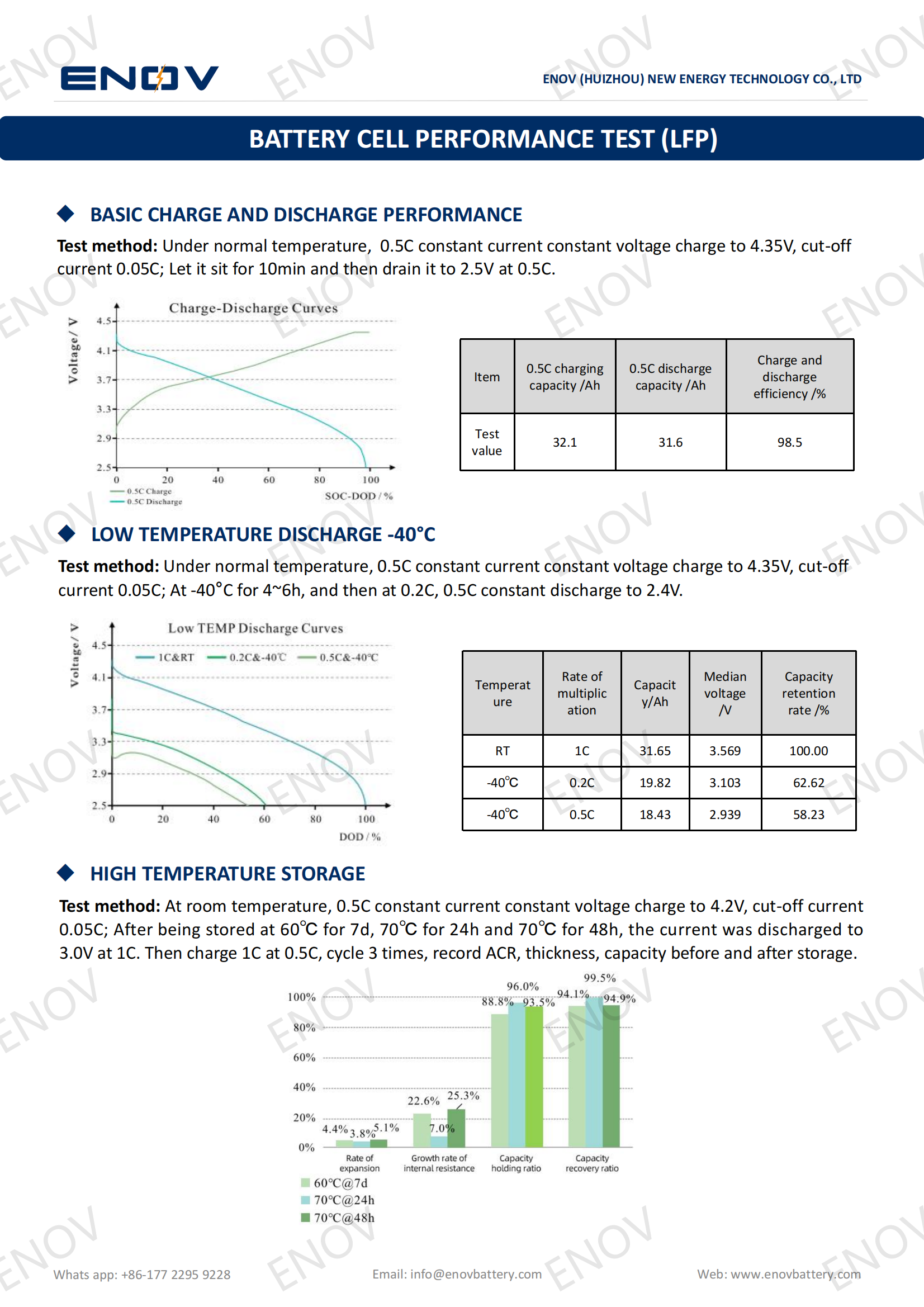

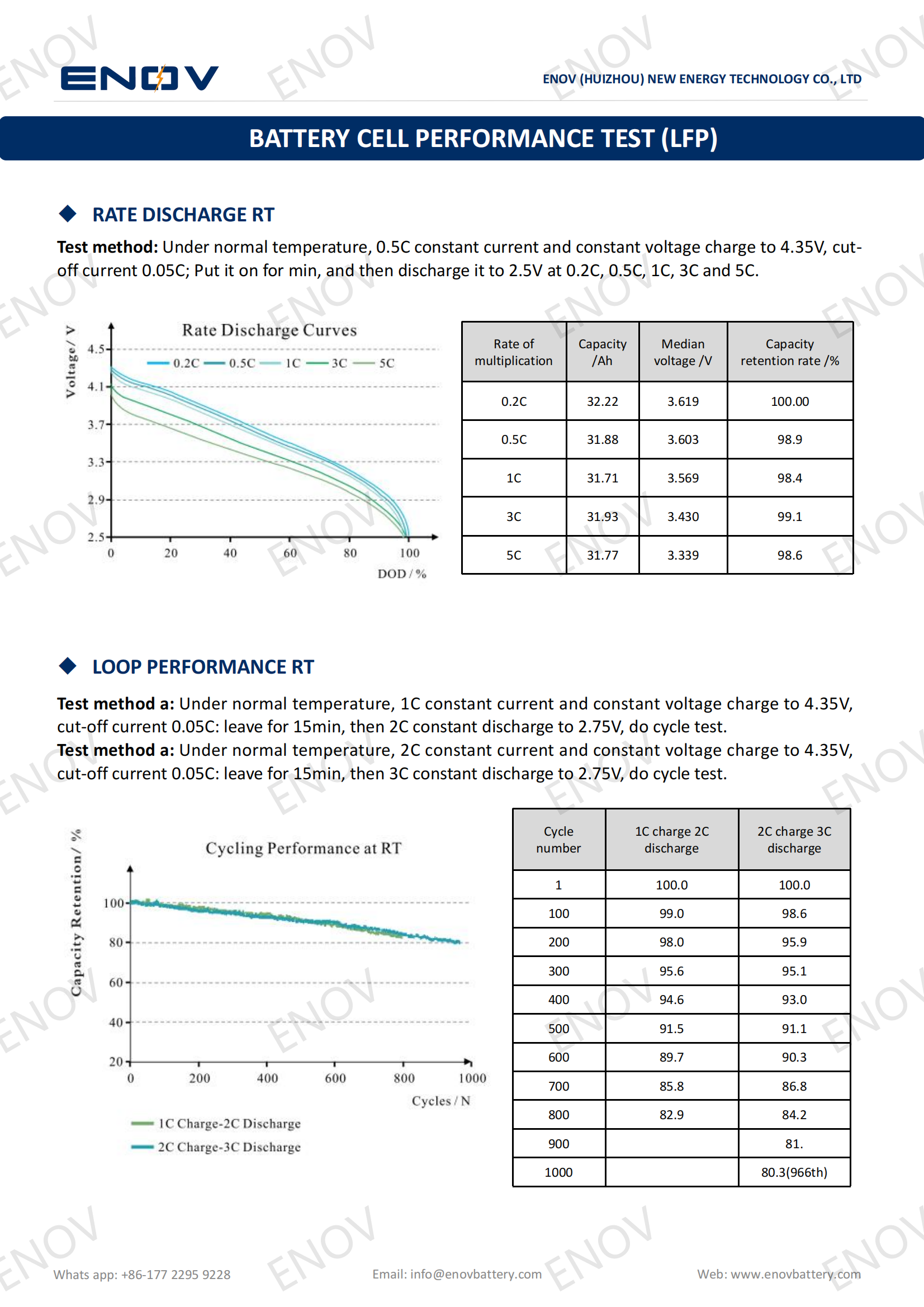

2. Product Test Reports

Ask the supplier for product test reports to ensure the product meets your specifications and requirements. For example, enovbattery includes test reports on basic charge-discharge performance, low-temperature (-40℃) discharge, high-temperature storage, and cycle performance in the appendix of its specifications.

3.Industry Standard Certifications and Necessary Certifications for the Importing Country

① Industry standard certifications: CE, ROHS, UN38.3, UL, and ISO9001. Factories with these certifications ensure their products are quality-assured, compliant, and safe.

② Necessary certifications for the importing country: Depending on the importing country, buyers must confirm whether there are other special product certification requirements locally to ensure compliance with local regulations; otherwise, customs clearance and product import/sales may be affected.

4. Brand Reputation and Customer Reviews

A brand’s reputation requires long-term maintenance by the factory. If possible, check for customer reviews of the factory on various platforms as a reference to avoid empty promises.

For example, one of my colleagues, Dora, had a cooperating client recommend a Brazilian distributor to her. This Brazilian client’s main product was not batteries but keyboards, and Dora still did her best to connect her with domestic keyboard manufacturers. The Brazilian client was very grateful to Dora, which also promoted further discussions on our company’s portable energy storage products.

Step 3: Assess Production Capacity

If you intend to cooperate with a factory long-term, managing your supply chain is crucial. Therefore, it is vital to ensure the supplier’s production capacity meets requirements and its raw material sources are stable.

You can try asking the supplier about its production capacity and on-time delivery rate in recent years, but this may involve the supplier’s trade secrets or competitive risks, so factories tend to be conservative. Obtaining such data may require a confidentiality agreement and long-term cooperation with the factory, with interest alignment to build trust and access the information.

Regarding drone battery customization by factories, I plan to write a dedicated article on this topic and will not elaborate here. Of course, if you already have clear customization needs, submitting them to the factory will prompt a response.

Step 4: Evaluate Communication Efficiency

1.Language Communication Difficulty

The abundance of translators does not mean the elimination of language barriers, as Ariana deeply understands. In exhibitions, calls, and message exchanges, I have experienced situations where differences in English accents or translator errors prevented this international language from bridging communication gaps with clients. My colleague Ranye also had a client whose phone lacked translation software, so the client replied two days later: “Sorry, I can’t understand.” Therefore, during communication, assess whether the language barrier with the supplier is too high, as this will affect your product and work efficiency—and is a prerequisite for a pleasant cooperation.

Enovbattery, however, guarantees every effort to reduce language barriers. For communication issues during on-site meetings or calls, we will involve multiple team members to ensure mutual understanding and finalize cooperation. If English messages or documents fail to communicate effectively, we will translate them into the client’s native language for easy reading. Ranye, for instance, helped that client download translation software on their phone to facilitate communication.

2. Real-time Response Speed

A supplier’s response speed to inquiries, feedback on production progress, and timely follow-up on after-sales product issues all reflect its real-time responsiveness. Quick responses can effectively avoid many problems.

Step 5: Analyze Cost Considerations

Understand the Supplier’s Pricing Strategy and Cooperation Models, and Analyze Cost-effectiveness

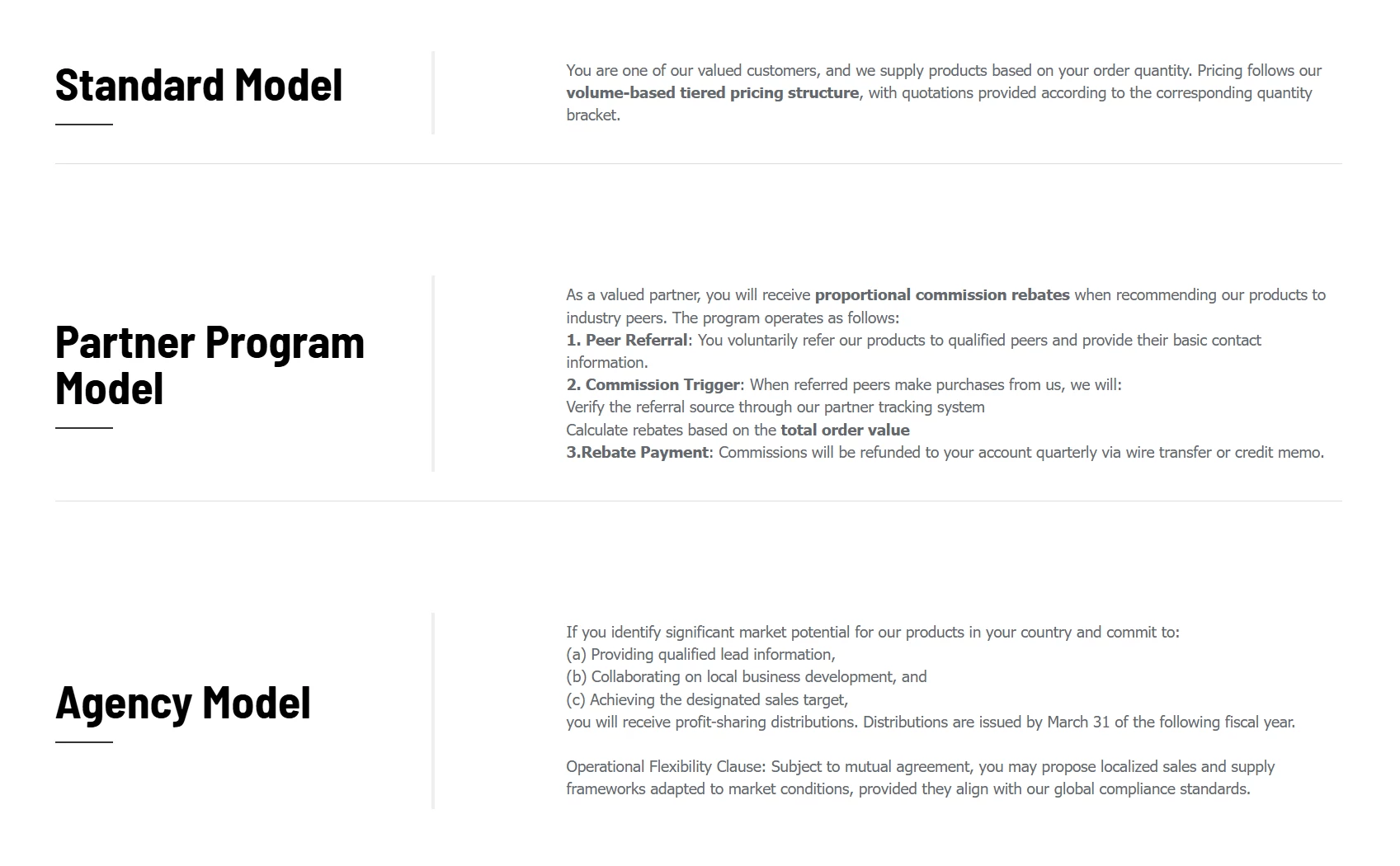

Suppliers targeting the B2B market typically have pricing based on order quantity or offer different cooperation models. For example, enovbattery has three cooperation models (as shown below). Integrating information collected in the previous four stages, you can calculate cost-effectiveness based on the supplier’s product quality, technology, and service quality. You can also compare prices across multiple factories to select the one suitable for your country. If the price of your preferred product is too high, you can negotiate with the supplier after collecting market prices, but avoid excessive price pressure to prevent quality degradation.

Different foreign trade contracts involve different costs. Do not overlook hidden costs such as transportation, insurance, labor, and tariffs.

Step 6: Lock in via Trial Production

You can first place a small sample order to conduct initial quality tests and assess whether cooperation with the supplier will be smooth. Despite the small order size, it still involves the entire process from production to delivery.

If satisfied with the product, try a medium trial order (500-1000 units) for in-depth product testing and market sales, gather end-user feedback, and negotiate adjustments with the supplier if issues arise.

After a successful medium trial, proceed to bulk orders to establish a stable supply source.

Quick inquiry

Drop us a line, and we’ll get back to you within 24 hours.

Ariana Yuan

Digital Operations Manager

Website Planning|Marketing Project Management for Drone Batteries|Scheduled Content Refresh|SEO Optimization

Ariana Yuan

Digital Operations Manager

Website Planning|Marketing Project Management for Drone Batteries|Scheduled Content Refresh|SEO Optimization