Comprehensive Analysis of Drone Battery Technology

Serving as the "power core" of drones, battery technology directly determines over 60% of a drone’s performance metrics. The global drone battery market is expanding at a 12.7% annual growth rate, surpassing $6.2 billion in 2023. Across consumer, industrial, and military applications, battery systems have evolved from basic energy storage devices into integrated solutions combining energy delivery, intelligent management, and environmental adaptability. With advancements in material science and digital integration, drone batteries are transitioning from passive energy sources to active enablers of next-generation aerial capabilities.

Strategic Role of Drone Batteries

Electrochemical Architecture:

o Current mainstream: NCM622 ternary cathode + graphite anode (240 Wh/kg energy density).

o Emerging solutions: NCMA quaternary cathodes paired with silicon-carbon anodes (lab-tested at 350 Wh/kg).

Key Parameters:

o Voltage: 3S (11.1V) to 6S (22.2V) configurations.

o Capacity: Ranges from 3,000mAh (30-minute flight) to 20,000mAh (1+ hours for industrial use).

o Discharge rate: Critical for high-thrust maneuvers (up to 100C in industrial models).

Power Delivery:

o Supplies >70% of total system energy for motors, flight controllers, and payloads.

o High-rate discharge (e.g., 100C) enables rapid climb rates (e.g., 15m/s ascent).

Operational Limits:

o Temperature range: Advanced batteries operate from -40°C (with self-heating) to 85°C.

o Cycle life: 800+ cycles (≥80% capacity retention) for premium industrial batteries.

3. Current Industry Landscape

Market Segmentation:

o Consumer drones: DJI dominates with 58% market share using standardized 3S-6S batteries.

o Industrial drones: Custom solutions thrive in agriculture (32% market share) and logistics.

Technical Challenges:

o Trade-offs between fast charging (30 minutes to 80%) and cycle life degradation (40% loss).

o Limited adoption of silicon anodes due to expansion issues during cycling.

4. Future Trends

Technology Roadmap:

o Short-term (2023–2025): Commercialization of silicon anodes (+30% capacity).

o Mid-term (2025–2028): Solid-state electrolytes (10x safety improvement).

o Long-term (2030+): Lithium-air batteries (theoretical 3,500 Wh/kg).

Smart Management:

o AI-driven predictive maintenance reduces field failures by 90%.

o 5G-enabled cloud BMS transmits 16 real-time parameters for fleet optimization.

Convergence of Innovation

Drone battery technology stands at the intersection of material breakthroughs and digital transformation. Three key trends will define the next decade:

1. Solid-state batteries will push energy density beyond 500 Wh/kg.

2. AI-powered diagnostics will enable preemptive maintenance, slashing operational downtime.

3. Wireless charging networks will unlock "energy-as-a-service" models for urban air mobility.

To capitalize on these opportunities, the industry must prioritize:

• Scaling high-nickel single-crystal cathode production.

• Optimizing solid-state electrolyte interfaces.

• Establishing closed-loop recycling systems.

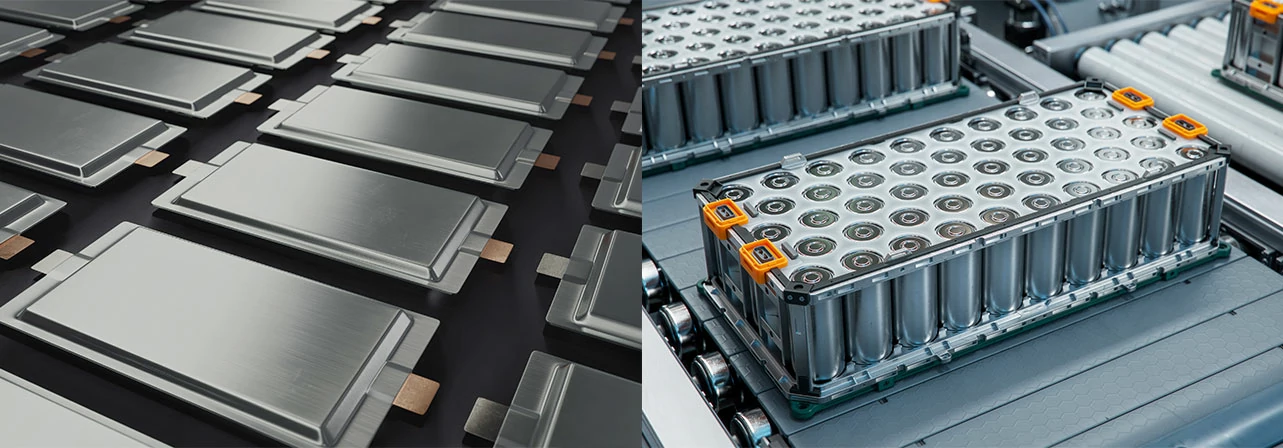

UAV DRONE battery

Enov UAV battery has the most advanced UAV battery new technology, it has a lightweight structural design, ultra-high energy density, stable continuous discharge, customized ultra-high instantaneous discharge, wide temperature working range, stable charge and discharge, battery materials can choose high nickel terpolymer positive/silicon carbon negative material system combined with semi-solid battery technology. Or choose a more mature application of more UAV lithium battery technology, available UAV battery nominal voltage 3.7V, capacity 18.0Ah ~ 30.0Ah, support 10C continuous discharge and 120C pulse discharge (3 seconds). With ultra-high energy density (220-300Wh/kg) as its core advantage, Enov UAV batteries can meet the needs of long-term endurance scenarios such as plant protection drones and transport drones, while maintaining stable emission performance in extremely low temperature environments (-40℃).

Other products

START-STOP LITHIUM BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!