The equalization technology of BMS

main content

In the starting lithium battery system of motorcycles, the performance differences among individual battery cells can significantly shorten the lifespan of the battery pack and cause safety hazards. Studies show that when the voltage difference between battery cells exceeds 50mV, the effective capacity of the battery pack will be lost by more than 15%, and the cycle life will be reduced by 30%. The balancing technology of the Battery Management System (BMS) has become the core means to ensure the performance of lithium batteries by eliminating the voltage/capacity differences between cells. This article analyzes the technological evolution and innovative breakthroughs of BMS for motorcycle lithium batteries from three dimensions: passive balancing, active balancing, and intelligent balancing.

Passive Equilibrium: The Game between Basic Protection and Energy Efficiency

1. Working Principle and Characteristics

Passive equalization discharges high-voltage cells through parallel resistors, dissipating excess energy in the form of heat to make the voltages of each cell tend to be consistent. The typical scheme adopts MOSFET to control the discharge circuit, and the balancing current is usually 50-100mA.

Its core advantage lies in:

Low cost: The hardware cost is only 1/5 of that of the active balancing solution, and it is suitable for 7-16 series small-capacity battery packs

Simple structure: Only resistors, MOSFETs and logic control circuits are required. It has excellent anti-vibration performance and is suitable for the complex working conditions of motorcycles

2. Technical bottleneck

Energy loss: When the 1A·h charge is balanced, 3.6kJ of heat is generated, resulting in a 5%-8% decrease in system efficiency

Capacity limitation: Compensation can only be made at the end of charging and cannot solve the problem of capacity difference during the discharging stage

Active Balance: An Efficiency Revolution in Energy Transfer

Technical implementation path

Active balancing achieves energy transfer across battery cells through inductors, capacitors or transformers, and is mainly divided into three categories:

Inductive storage and transportation type: Utilizing the BUCK-BOOST topology to transfer energy between adjacent cells (with an efficiency of 85%-92%)

Capacitive shuttle type: Energy exchange between any battery cells is achieved through a switch matrix (the equalization speed is increased by 3 times)

Transformer coupling type: High-frequency transformers are used to achieve cross-module energy scheduling, suitable for high-voltage systems above 72V.

Intelligent Balance: Dynamic Strategies and AI Empowerment

Multi-parameter collaborative control

The intelligent balancing system integrates the SOC/SOH estimation algorithm to achieve the adjustment of dynamic balancing strategies:

Temperature compensation: Automatically switches to small current equalization (0.1C) at a low temperature of -30℃ to prevent the growth of lithium dendrites

Working condition perception: Identify the driving state through vibration sensors and pause the balancing operation on bumpy roads.

Conclusion

From passive balanced energy dissipation to intelligent balanced AI empowerment, the BMS technology of motorcycle lithium batteries is undergoing a paradigm shift from "extensive compensation" to "precise regulation".

START-STOP LITHIUM battery

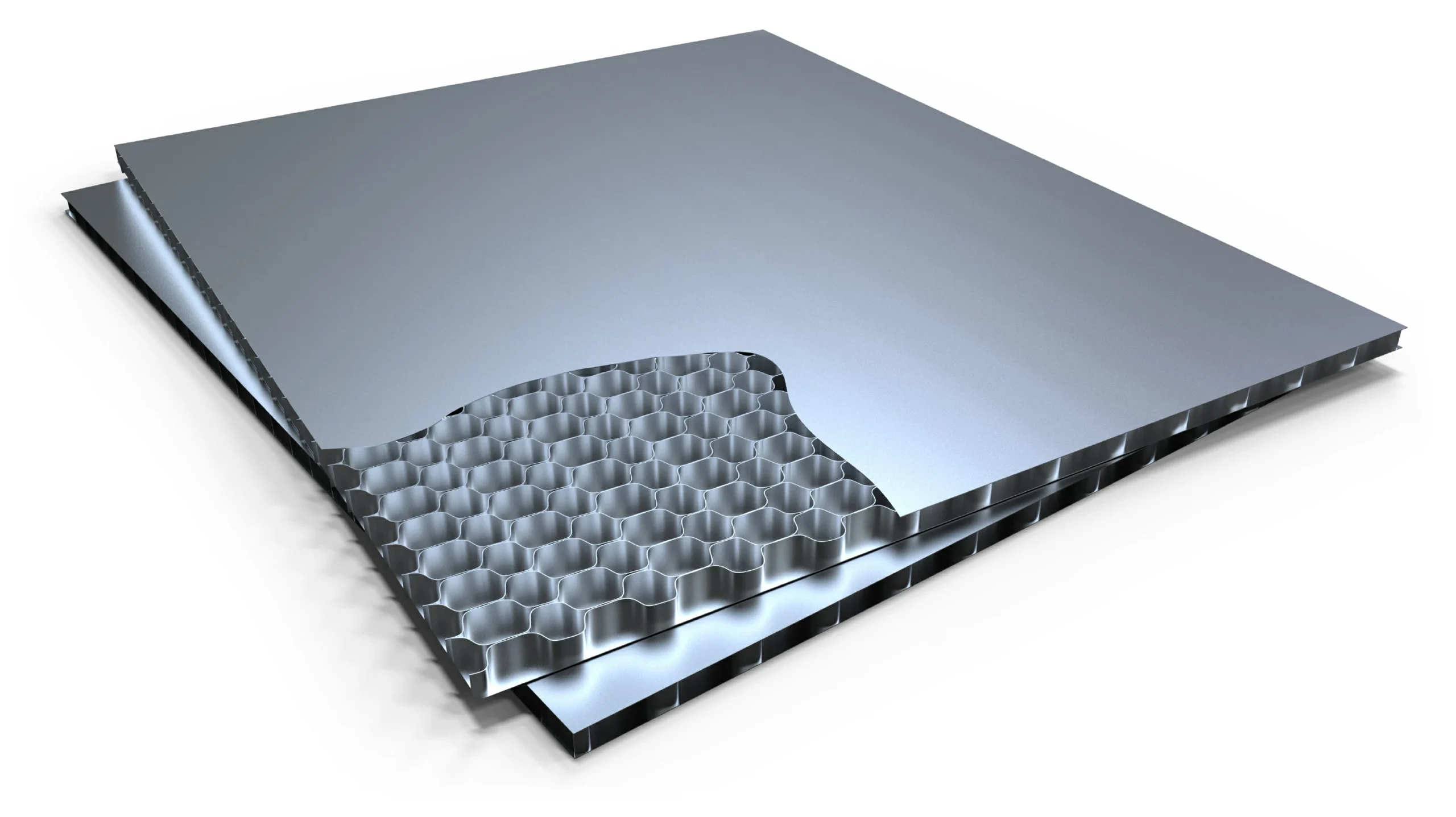

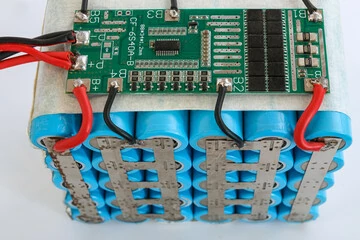

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!