Seismic structure optimization - Honeycomb support

main content

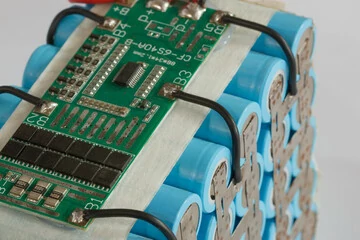

When a motorcycle is traveling on rough roads, the lithium battery needs to withstand an acceleration impact of up to 15G. The traditional battery bracket adopts a rigid fixed structure, which is prone to cause the accumulation of micro-displacements between battery cells, leading to problems such as electrode sheet breakage and electrolyte leakage. In recent years, honeycomb-shaped supports have become the core breakthrough point in the seismic design of lithium batteries due to their unique mechanical properties. Studies show that honeycomb structures can increase the absorption efficiency of mechanical vibration energy by more than 40% and reduce the peak stress between battery cells by more than 30% at the same time.

The damage mechanism of motorcycle vibration to lithium batteries

High-frequency resonance damage: The vibration frequency of the motorcycle engine is concentrated in the range of 200-500Hz, which is prone to resonance with the natural frequency of the lithium battery module (150-800Hz), increasing the fatigue fracture probability of the TAB welding point by 5-8 times.

Multi-directional shear stress: The three-dimensional vibration waves generated by the bumpy road surface are transmitted through the vehicle frame to the battery pack. When the shear strain of the polypropylene (PP) separator is greater than 3%, the porosity drops by 40%, and the lithium-ion transmission impedance surges.

Cumulative plastic deformation: Long-term vibration causes plastic deformation of 0.1-0.3mm in the battery cell casing, with an annual growth rate of internal resistance reaching 15%, and the capacity attenuation rate is three times higher than that under static conditions.

The seismic resistance principle of honeycomb-shaped supports

Topological structure optimization

The honeycomb support adopts a hexagonal periodic arrangement design, and its mechanical properties are manifested as follows:

Stress dispersion effect: A single honeycomb cell can disperse the local impact load to six adjacent cells, reducing the concentrated stress of 3MPa to 0.7MPa.

Energy dissipation mechanism: The honeycomb wall absorbs vibration energy through elastic buckling deformation, with an energy conversion efficiency of 85% (while traditional rubber pads only have 45%).

Frequency decoupling feature: By adjusting the honeycomb aperture (5-20mm) and wall thickness (0.5-2mm), the natural frequency of the module can be tuned outside the vibration frequency band, avoiding the risk of resonance.

Innovation in Materials Science

High-performance composite materials: The PC-PBT (Polycarbonate - polybutylene terephthalate) material developed by Covestro still maintains an elongation at break of 120% at -40℃ and has an impact strength of up to 85kJ/m².

Gradient modulus design: The outer layer adopts high-modulus carbon fiber reinforced epoxy resin (elastic modulus 120GPa), and the inner layer uses low-modulus silicone foam (elastic modulus 0.05MPa) to achieve wideband vibration attenuation.

Dynamic mechanical matching

Damping characteristic regulation: The honeycomb wall surface is coated with a butyl rubber-graphene composite coating (loss factor 0.8), which can convert 200Hz vibration energy into heat energy, with a temperature rise rate of ≤1℃/min.

Limit buffer design: A wedge-shaped protrusion structure is set at the edge of the bracket to limit the displacement of the battery cells along the X/Y/Z axes (≤0.2mm/0.15mm/0.1mm respectively).

Conclusion

The honeycomb-shaped support, through the deep integration of bionic topology optimization and advanced materials engineering, provides a brand-new paradigm for the seismic design of lithium batteries. From the stress dispersion mechanism of hexagonal cells to the energy dissipation path of gradient composite materials, this technology is redefining the reliability boundary of power batteries under extreme working conditions.

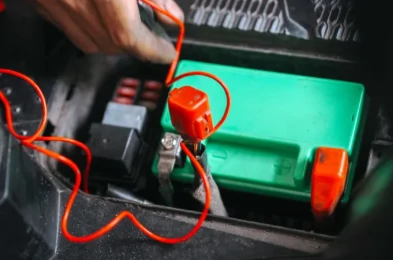

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!