High-rate discharge optimization

main content

The moment a motorcycle starts, the battery needs to output hundreds of amperes of pulse current within milliseconds (usually reaching a rate of over 10C), which poses strict requirements for the dynamic performance of lithium batteries. Traditional lead-acid batteries are unable to meet the demands due to their excessively high internal resistance, while lithium batteries are breaking through the technical barriers of high-rate discharge through material system reconstruction and structural innovation. From electrode nanoscale to interface ion transport optimization, a series of technological innovations have enabled lithium batteries to maintain stable high power output in complex scenarios such as low temperatures and vibrations. This article will analyze the core principles and technical paths of high-rate discharge optimization.

Technical challenges of high-rate discharge

1.The polarization effect intensifies

When discharging above 10 ° C, the diffusion rate of lithium ions in the electrode material is out of balance with the electron transport rate, resulting in the superposition of concentration polarization and electrochemical polarization, and the voltage drop can reach more than 30%. Lithium iron phosphate (LiFePO₄) cathode is more prone to capacity drop at high rates due to its low intrinsic electronic conductivity (approximately 10⁻⁹ S/cm).

2. The interface impedance surges sharply

The solid electrolyte interface film (SEI) formed at the electrode/electrolyte interface repeatedly ruptures and reorganizes during high-rate charging and discharging, causing the interface impedance to surge from 50Ω·cm² at room temperature to 200Ω·cm² at low temperatures.

3. Risk of thermal runaway

The Joule heat generated by continuous high-rate discharge can cause the cell temperature to rise by 5 to 8 degrees Celsius per minute. If the heat dissipation design is insufficient, a local temperature exceeding 80 degrees Celsius will lead to the decomposition of the electrolyte and the contraction of the separator.

High-rate discharge optimization strategy

1.Innovation in material systems

Nanocomposite cathode: By reducing the particle size of LiFePO₄ to 100-200nm and coating it with a carbon nanotube/graphene composite conductive layer, the electron migration rate is increased by three times, and the discharge capacity retention rate at -20 ° C at 10 ° C reaches 92%.

Three-dimensional porous anode: By using a hard carbon/silicon composite anode and regulating the porosity (35%-40%) and interlayer spacing (0.37-0.42nm), the lithium-ion diffusion coefficient is increased from 10⁻¹⁴ to 10⁻¹² cm²/s.

2. Electrolyte kinetics optimization

Low-viscosity solvent system: Replace the traditional ethylene carbonate (EC) with ethyl acetate (viscosity 0.45 mPa·s), and combine it with LiBF₄ lithium salt to ensure that the electrolyte maintains an ionic conductivity of > 8 mS/cm at -30℃.

Fluorinated interface additive: Add 1%-2% fluorinated vinyl carbonate (FEC) to induce the formation of a LiF-rich SEI film, reducing the interface impedance to 25Ω·cm².

3. Structural Engineering design

Ultra-thin electrode process: The thickness of the cathode is reduced from 120μm to 80μm. Combined with the serpentine flow channel current collector design, the lithium-ion transport path is shortened by 40%, and the internal resistance is reduced to 0.8mΩ.

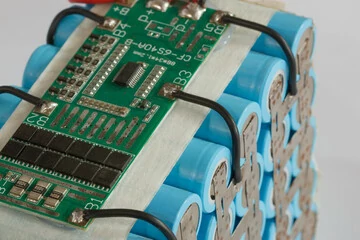

Cylindrical cell packaging: It adopts a 26650 cylindrical structure. Through the design of a ring-shaped metal shell and a central pressure relief valve, the heat dissipation efficiency at 10C discharge is 60% higher than that of square cells.

4. Intelligent thermal management technology

Gradient temperature control BMS: Based on the Kalman filtering algorithm, it estimates the cell temperature in real time, dynamically adjusts the discharge rate, and automatically derates to 8 ° C when the temperature exceeds 45 ° C.

Phase change energy storage material: Paraffin/expanded graphite composite material (phase change latent heat ≥180 J/g) is filled in the gap of the battery cell to control the temperature rise rate at 1.5℃/min during continuous discharge at 10 ° C.

Conclusion

From the regulation of the solvation structure of the electrolyte at the molecular scale to the modular heat dissipation design at the macroscopic scale, the high-rate discharge optimization of motorcycle starting lithium batteries demonstrates the technical charm of multi-disciplinary collaborative innovation. With the continuous breakthroughs in solid-state interface engineering and intelligent BMS algorithms, lithium batteries are redefining the physical boundaries of power output, providing a more powerful "heart" for high-performance motorcycles and even electric aircraft.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!