Low-temperature adaptability optimization

main content

In extremely cold environments with temperatures as low as minus tens of degrees Celsius, motorcycles often get into trouble when starting up due to a sudden drop in battery performance. The capacity of traditional lead-acid batteries can decline by more than 50% at low temperatures. Although lithium batteries have the advantage of high energy density, their low-temperature adaptability still needs to break through the dual limitations of material physical properties and electrochemical kinetics. In recent years, through the modification of positive and negative electrode materials, the innovation of electrolyte formulas, and the coordinated optimization of intelligent thermal management systems, motorcycle starting lithium batteries have achieved reliable cold starting in an environment of -40℃. This article will analyze the technological breakthroughs and innovation paths in this field.

Technical challenges in low-temperature environments

Lithium batteries mainly face three challenges in low-temperature environments:

1. Electrolyte solidification and viscosity surge: The viscosity of conventional carbonate electrolytes rises to 15 times that of normal temperature at -20℃, increasing the resistance to lithium ion migration, leading to an increase in internal resistance and capacity attenuation.

2. Reduced lithium intercalation efficiency of the anode: The interlayer spacing of the graphite anode (approximately 0.335nm) is difficult to maintain the rapid diffusion of lithium ions at low temperatures, which easily leads to the growth of lithium dendrites and poses a safety hazard.

3. Intensified polarization of cathode materials: The discharge capacity of lithium iron phosphate (LiFePO₄) at -20℃ is only 33% of that at room temperature. Its olivine structure leads to poor electronic conductivity, and the ion diffusion rate drops significantly at low temperatures.

Low-temperature adaptability optimization strategy

1.Reconstruction of the material system

Cathode nanoscale treatment: Reduce the particle size of LiFePO₄ to 100-200nm, shorten the lithium-ion diffusion path, and increase the discharge capacity at -20℃ to 94% of that at room temperature. Ternary materials (NCM) can reduce low-temperature polarization through Al doping and coating with fast ion conductors. For instance, the composite cathode developed by Tianfeng Power still maintains 70% capacity at -40℃.

Negative electrode interlayer spacing control: By using hard carbon materials with an interlayer spacing of 0.37nm or tin-coated graphite, the lithium-ion diffusion impedance is reduced by 3 to 10 times, while lithium dendrites are suppressed.

2. Low-temperature adaptation of electrolyte

Solvent system optimization: Replace the traditional EC solvent with low-viscosity chain carboxylic acid esters such as ethyl acetate and ethyl propionate, so that the viscosity of the electrolyte is less than 5 mPa·s at -40℃.

New lithium salt and additive: LiBF₄ replaces LiPF₆ to increase capacity retention from 72% to 86% at -30 ° C; The addition of fluoroethylene carbonate (FEC) increases the content of LiF in the SEI film and reduces the impedance by 50%.

3. Intelligent thermal management system

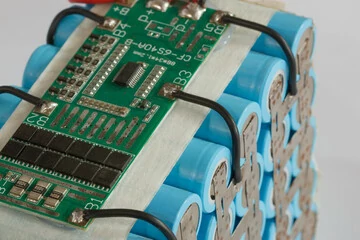

BMS preheating technology: By self-heating with pulsed current or PTC heating film, the temperature of the battery cell is raised to above -20℃ before startup. The BMS of Lilang battery can achieve a temperature rise rate of 10℃/min, avoiding low-temperature lithium plating.

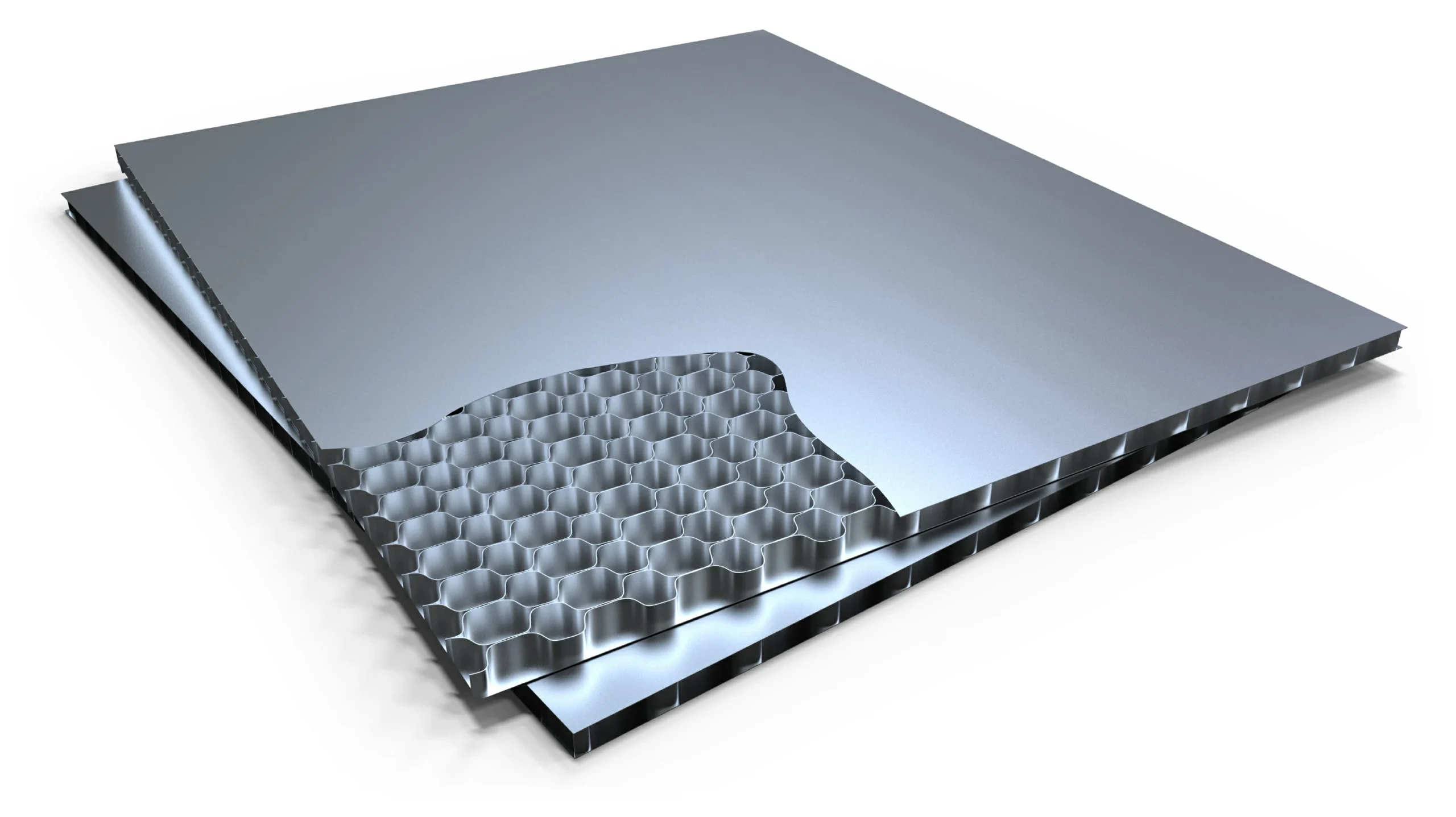

Phase change material insulation: The paraffin/graphite composite material releases latent heat during the phase change process, maintaining the temperature stability of the battery pack. Compared with the traditional air-cooling scheme, the temperature fluctuation is reduced by 40%.

4. Innovative structural design

Low internal resistance electrode sheet process: High-conductivity carbon nanotubes are used to replace traditional conductive agents, increasing the electrode porosity to 35% and making the ion transport channels more unobstructed.

Compact module layout: The 7th generation battery of Tianfeng Power adopts a soft-pack lamination process, with a volume energy density of up to 400Wh/L. Meanwhile, it achieves ±2℃ temperature uniformity control through a serpentine flow channel liquid cooling plate.

Conclusion

The low-temperature adaptability optimization of the starting lithium battery for motorcycles demonstrates the deep collaboration between material chemistry and engineering design. From the fine tailoring of the solvent molecular chains in the electrolyte to the dynamic compensation of the BMS algorithm, technological breakthroughs have always centered on the core goal of "reducing the ion migration barrier".

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!