Anti-corrosion design for battery cells

main content

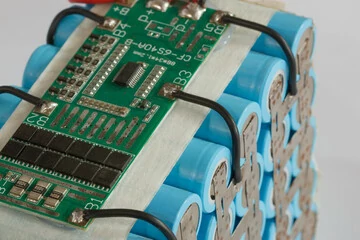

In modern battery technology, the anti-corrosion design of battery cells is an important link to ensure battery performance and safety. During the usage of battery cells, they may be affected by various corrosion factors, such as electrolyte leakage and electrochemical corrosion between metal components. These corrosion problems not only reduce the performance of the battery, but also may lead to safety hazards. Therefore, a scientific and reasonable anti-corrosion design is particularly important. This article will provide a detailed introduction to the key technologies and applications of anti-corrosion design for battery cells.

Core Technologies for Anti-corrosion Design of Battery Cells

Anti-corrosion treatment of dissimilar metal interfaces

The interfaces of dissimilar metals commonly found in battery cells, such as the connection between aluminum and copper, are high-risk areas for electrochemical corrosion. To prevent this kind of corrosion, a layer of nickel or zinc is usually plated on these interfaces. The coating can effectively isolate the two metals and prevent electrochemical corrosion caused by potential difference. For instance, at the connection points of the busbar, nickel or zinc plating can significantly enhance the corrosion resistance of the connection and extend the service life of the battery cells.

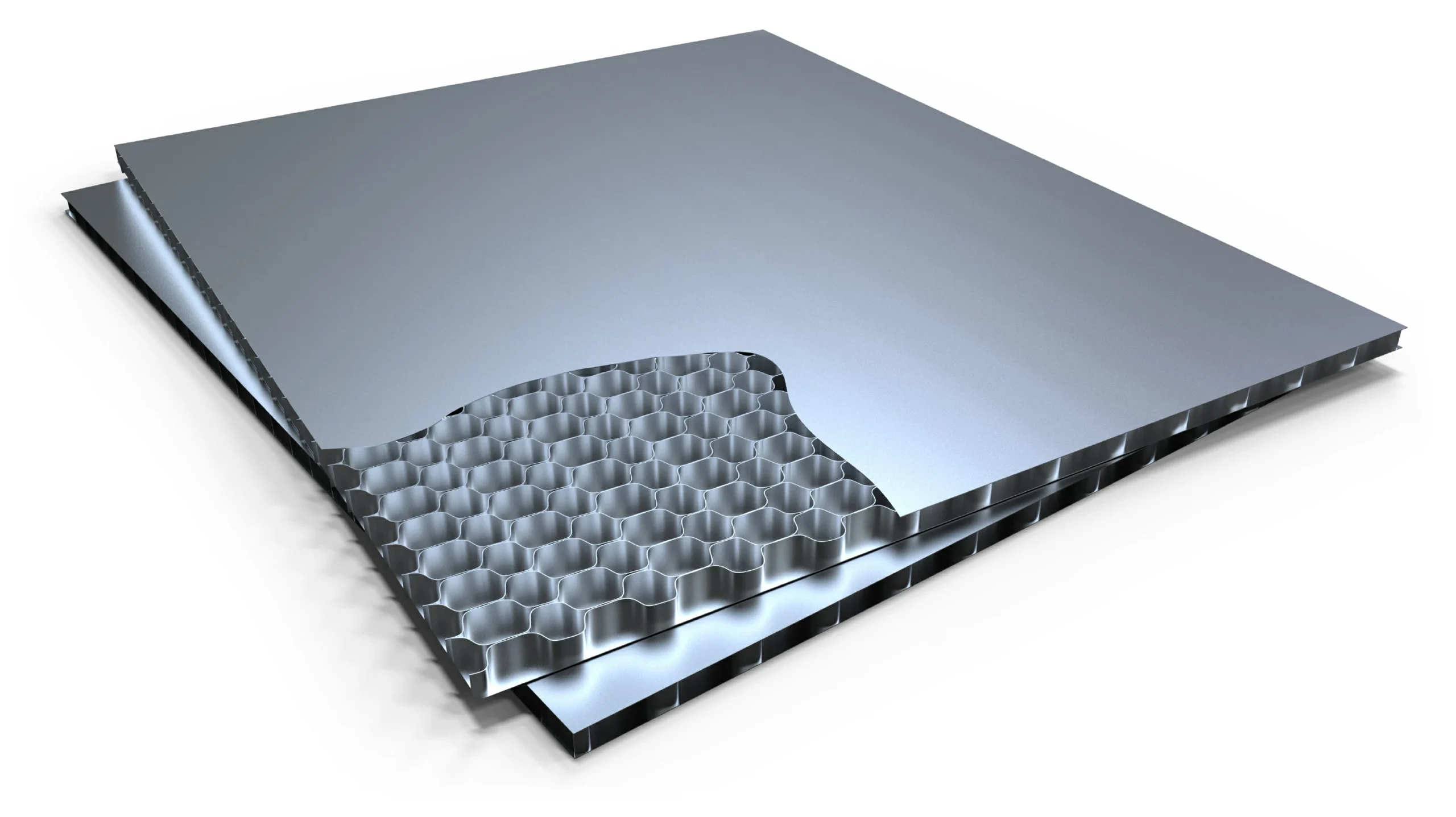

Optimal design of the packaging structure

The design of the battery packaging structure is equally important for anti-corrosion. A common optimization method is to adopt a non-vertical design of the connection structure between the tabs and the housing. This design can reduce local stress during the packaging process and prevent shell damage caused by stress concentration. Meanwhile, by creating an anti-corrosion space between the tabs and the casing and filling it with inert gases (such as helium, neon, argon, etc.), the risk of electrolyte corrosion can be further reduced.

The application of anti-corrosion coatings

Anti-corrosion coating is another effective means of anti-corrosion. For instance, polyaniline/silicon strong powder composite coatings have been proven to have excellent anti-corrosion performance in harsh environments. This coating significantly reduces the corrosion rate by forming a protective film to prevent the metal from coming into contact with corrosive media. The electrochemical performance test shows that both the corrosion current and the corrosion potential have significantly decreased, demonstrating a good protective effect.

The Importance of Anti-corrosion Design for Battery Cells

Extend battery life

Anti-corrosion design can effectively reduce the corrosion of the metal components inside the battery cell, thereby extending the service life of the battery. By reducing the problems of short circuits and leakage caused by corrosion, the performance and reliability of batteries have been significantly improved.

Improve security

Anti-corrosion design can effectively prevent electrolyte leakage and internal short circuits of the battery, reducing safety risks caused by corrosion, such as fire and explosion. This is crucial for the safety of battery-powered devices and users.

Adapt to complex environments

The anti-corrosion design enables the battery to better adapt to various complex usage environments, such as high humidity, high salt spray and other harsh conditions. This is particularly important for battery devices used outdoors, ensuring that the battery can still function properly in harsh environments.

Future Development Directions of Anti-corrosion Design for Battery Cells

With the continuous advancement of battery technology, the anti-corrosion design of battery cells is also constantly evolving. In the future, anti-corrosion design may place greater emphasis on intelligence and multi-functionality. For instance, develop intelligent coatings that can monitor the corrosion state in real time, as well as composite coatings that combine multiple protection mechanisms. In addition, the research and development of new materials will also provide more possibilities for the anti-corrosion design of battery cells.

Conclusion

Anti-corrosion design for battery cells is an indispensable part of battery technology. By optimizing the interface treatment of dissimilar metals, the design of packaging structures, and the application of anti-corrosion coatings, the performance and safety of batteries can be significantly enhanced. With the continuous advancement of technology, the anti-corrosion design of battery cells will provide more reliable guarantees for the wide application of batteries, promoting the development of battery technology towards higher performance and greater safety.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!