Temperature fuse

main content

Battery cell temperature fuses, as an important safety protection device, are widely used in battery management systems (BMS) and battery tabs. They can quickly cut off the current in abnormal high-temperature conditions to prevent safety accidents caused by battery overheating. This article will provide a detailed introduction to the working principle, significance and current application status of battery cell temperature fuses in battery safety.

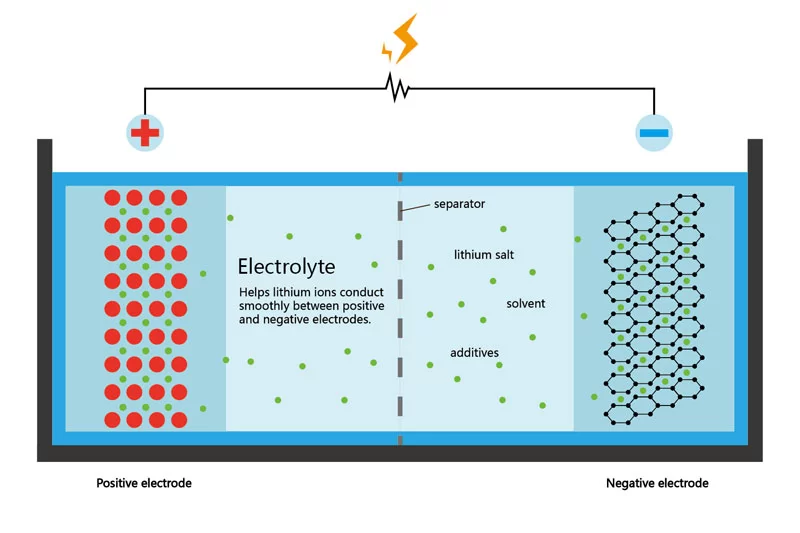

Working Principle of Temperature Fuses

The core of a temperature fuse is a temperature-sensitive element, which is usually made of low-melting-point alloys or fusible conductive materials. When the temperature inside or outside the battery rises to the set threshold (usually above 90℃) due to short circuits, overcharging or other reasons, the temperature-sensitive components will melt or break. This change will trigger the mechanical movement inside the fuse, cutting off the circuit and thus stopping the current flow. The temperature fuse is disposable. Once triggered, it must be replaced.

The Importance of Temperature Fuses

Preventing battery overheating: Under abnormal conditions (such as short circuits, overcharging, overdischarging, etc.), batteries generate a large amount of heat. A temperature fuse can quickly cut off the circuit when the temperature exceeds the safety threshold, preventing thermal runaway caused by overheating of the battery.

Ensuring equipment safety: The rapid response of temperature fuses can effectively prevent fires or explosions caused by battery overheating, protecting the safety of equipment and users.

Extending battery life: By promptly cutting off the current, the temperature fuse can reduce the damage to the battery at high temperatures and extend the battery's service life.

Current Application Status of Temperature Fuses

Thermal fuses are widely used in various battery systems, especially in lithium batteries, where their importance is increasingly prominent. With the increasing demand for portability of electronic devices, the size of thermal fuses is constantly shrinking. Currently, the thinnest thermal fuse is only 0.65mm thick. In addition, the internal resistance of the temperature fuse is very small, usually only about 8mΩ, and it hardly affects the normal operation of the battery.

Future Development Trends

With the continuous advancement of battery technology, temperature fuses are also constantly being optimized. In the future, temperature fuses may integrate more intelligent functions, such as deep integration with battery management systems (BMS), to achieve more precise temperature monitoring and protection. Meanwhile, researchers are also exploring materials with higher performance to further enhance the reliability and response speed of temperature fuses.

Conclusion

As a key line of defense for battery safety, the battery cell temperature fuse provides a reliable guarantee for the safe operation of the battery through its simple and efficient working principle. With the continuous advancement of technology, temperature fuses will play a greater role in the field of battery safety.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!