Safety and protection device of battery cell

main content

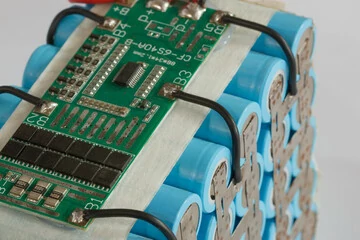

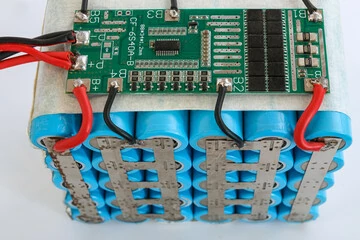

The safety of lithium batteries for starting motorcycles is of vital importance. Especially as the core component of the battery, the battery cells need to be equipped with various safety and protection devices to ensure their reliability and safety under various working conditions. Among them, the pressure relief valve, temperature fuse and anti-corrosion design are the key components of the battery cell safety protection. These devices work together through different mechanisms, effectively reducing the risk of batteries in abnormal situations and ensuring the safety of users.

The pressure relief valve is an important device in lithium battery cells used to prevent excessive internal pressure from causing danger. Its working principle is based on a pressure balance mechanism. When the internal pressure of the battery exceeds the preset safety threshold, the pressure relief valve will automatically open to release the excess pressure and restore the system pressure to a safe range.

A temperature fuse is an overheat protection component that can cut off the circuit when the battery temperature rises abnormally, preventing safety issues caused by overheating.

Lithium batteries are affected by environmental factors during use, such as humidity and salt spray. Therefore, anti-corrosion design is crucial for extending battery life and ensuring safety.

Conclusion

The safety and protection devices for the starting lithium battery cells of motorcycles are important components to ensure their reliability and safety. The pressure relief valve prevents battery rupture or explosion by controlling the internal pressure. A temperature fuse can cut off the circuit when the battery temperature rises abnormally, preventing the danger caused by overheating. The anti-corrosion design ensures the stability of the battery in complex environments through multiple measures. The synergistic effect of these devices provides a solid guarantee for the safe use of lithium batteries for starting motorcycles.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!