Pole lugs and connectors

main content

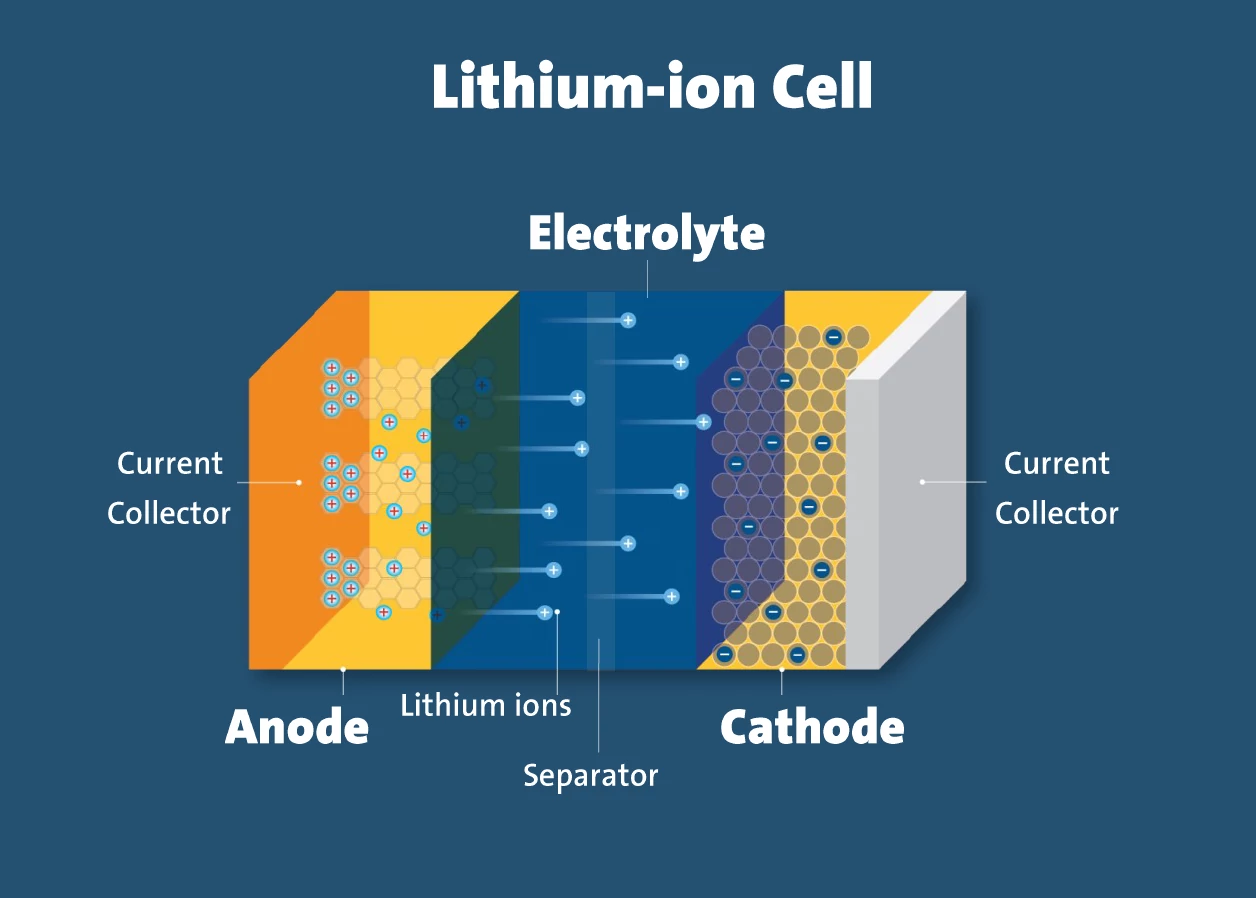

In the microscopic world of the starting lithium battery of a motorcycle, the tabs and connectors are like the "highway toll stations" of electric current, undertaking the core mission of efficiently transmitting the current generated by the active substances inside the battery cell to the external circuit. These seemingly simple metal components need to maintain ultra-low impedance under instantaneous current impacts of over 300A, while ensuring structural stability under harsh working conditions such as vibration and alternating high and low temperatures. This article will analyze the technical mysteries of tabs and connectors from two dimensions: materials science and process technology.

pole lugs material

1. Positive electrode TAB: The oxidation wisdom of aluminum material

The positive electrode tabs of the motorcycle lithium battery are made of 1070 pure aluminum (aluminum content ≥99.7%), and its technical characteristics include:

Conductivity optimization: The resistivity is 2.65×10⁻⁸Ω·m. Through the cold rolling process, the grains are arranged along the < 111 > crystal direction, and the electron mobility is increased to 3.5×10⁷ S/m.

Surface passivation layer: A 4-6nm thick Al₂O₃ film is formed through natural oxidation. The corrosion rate drops to 0.15mg/cm²/ year at a high potential of 4.2V (1.2mg/cm²/ year for aluminum materials without an oxide layer).

Mechanical properties: Tensile strength ≥120MPa, elongation ≥15%, meeting the fatigue resistance requirements of motorcycles under vibration conditions.

2. Negative electrode TAB: The conductive philosophy of copper materials

The negative electrode tabs are made of T2 red copper (copper content ≥99.9%), and its core advantages lie in:

Ultimate electrical conductivity: Resistivity 1.68×10⁻⁸Ω·m. Through annealing process, the grain boundary density is reduced to 10⁴/cm², and the average free path of electrons is increased to 40nm.

Interface stability: At a low potential of 0.1V, the gas production from the side reaction between copper and the electrolyte is less than 0.1mL/Ah. Lithium plating can be further inhibited through nickel plating treatment (with a nickel layer thickness of 2μm).

Mechanical strength: Hardness HV≥80, yield strength ≥220MPa, ensuring that the tabs do not deform under a shear force of 200N

Welding process

1.Ultrasonic welding: molecular-level bonding of aluminum tabs

Principle: The 20kHz high-frequency vibration generates local frictional heat (approximately 300℃), causing the lattice on the surface of the aluminum material to reorganize and form a metallurgical bond.

Parameter optimization: Welding energy 35-50J, pressure 0.4-0.6MPa, achieving a contact resistance of 0.8-1.2mΩ;

Microstructure: The grain size in the weld zone is refined to 5-10μm (50μm for the base metal), and the tensile strength is increased by 30%.

2. Laser welding: Photon energy control of copper tabs

Beam control: A 1064nm fiber laser is adopted, with a power density of up to 10⁶W/cm², and the molten pool depth is precisely controlled to 0.1-0.3mm.

Weld seam characteristics: The cooling rate reaches 10⁶K/s, forming ultrafine equiaxed grains (1-3μm), and the electrical conductivity remains 98% of the base material;

Defect suppression: The porosity was reduced to below 0.05% through argon protection (flow rate 15L/min), and the pore size was < 10μm.

Conclusion

The tabs and connectors of the lithium battery for motorcycle starting are the key components to ensure the performance and reliability of the battery. From material selection to welding techniques, every step is infused with precise scientific principles and engineering designs. By optimizing material properties and welding processes, the current transmission efficiency, cycle life and safety of batteries can be significantly enhanced.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!