Composite collector and future trends

main content

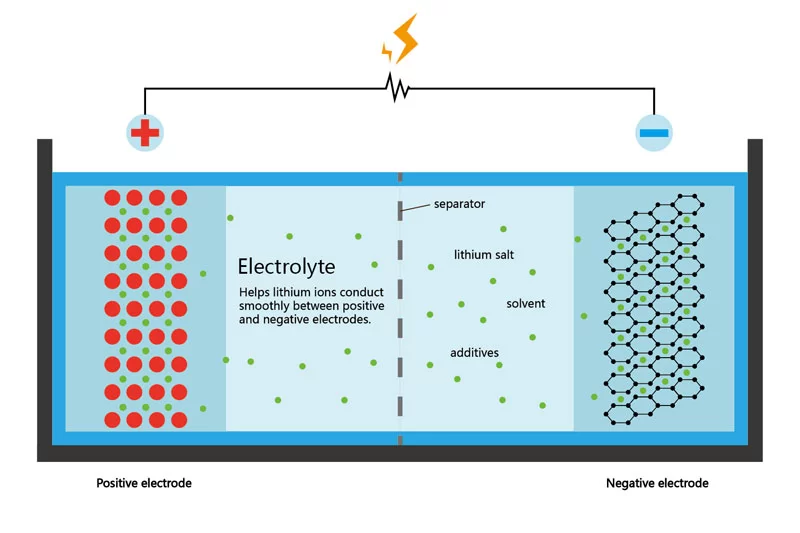

In the microscopic world of the starting lithium battery of a motorcycle, the current collector is like a "highway" for power transmission, undertaking the core mission of collecting current, carrying active substances and optimizing energy transfer efficiency. From traditional metal foils to revolutionary composite structures, the evolution of current collectors not only drives a leap in energy density but also triggers a technological revolution in the fields of safety and lightweighting. This article will conduct an in-depth analysis of the scientific characteristics of composite current collectors and reveal how these nanoscale materials support the powerful instantaneous burst of motorcycles.

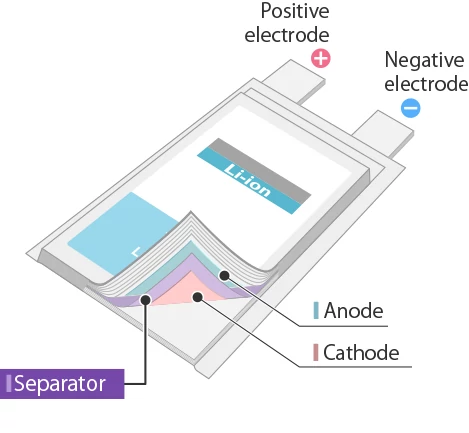

A "metal-polymer-metal" composite system was formed by double-sided plating of a 1μm copper layer (or a 2μm aluminum layer) on a 4μm PET substrate film:

Weight reduction: Compared with traditional copper foil, it reduces the weight by 67%, lowering the overall weight of the 12V battery pack from 1.2kg to 0.8kg.

Energy density leap: The mass energy density has increased by 5.6%, and the lithium iron phosphate battery can reach 160Wh/kg.

Safety performance breakthrough: During the needle-puncture test, the composite copper foil produced a "circuit breaking effect", and the thermal runaway trigger temperature rose from 150℃ to 210℃.

2. Breakthroughs in interface engineering

Magnetron sputtering transition layer: A 2nm titanium layer is deposited on the PET surface, and the bonding strength of the copper layer is increased to 8N/cm, with a cyclic expansion rate of less than 0.3%.

Self-healing coating: By adding polymers containing dynamic disulfide bonds, micro-cracks in the coating can be repaired at 80℃, and the cycle life can be extended by 300%.

3. Low-temperature performance optimization

By using PP base film instead of PET, the electrolyte immersion time at -40℃ is shortened from 60 seconds to 15 seconds, and the lithium ion migration rate is increased by 50%, meeting the extremely cold starting requirements of motorcycles.

Future trend: From metal foil to smart conductors

Solid-state battery adaptation: Develop 3μm ultra-thin composite aluminum foil, reducing the interface impedance with sulfide solid electrolyte to 5Ω·cm²;

Ai-optimized manufacturing: Utilizing machine learning to predict coating defects, the yield of composite current collectors has been increased from 60% to 90%.

Bio-based materials: Cellulose nanofiber composite current collector, carbon emissions reduced by 70%, biodegradation rate > 90%;

Topological structure innovation: Bionic honeycomb-shaped copper coating, with a specific surface area increased by five times, supporting the release of 4200mAh/g capacity of silicon-carbon anodes.

Conclusion

From the oxidation wisdom of aluminum foil to the cross-border integration of composite current collectors, the current collector technology of motorcycle starting batteries is reshaping the physical boundaries of energy transmission. When a 6μm composite copper foil carries an instantaneous current of 300A/cm², and when the PET base film triggers an intelligent circuit breaker at the moment of needle puncture, these nanoscale innovations are writing a brand-new chapter for the power revolution of two-wheeled motor vehicles. In the future, with the deep integration of materials genetic engineering and intelligent manufacturing, current collectors may evolve into "neural veins" with self-perception and self-adaptation capabilities, making every throttle turn a perfect resonance of technology and power.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!