Positive and negative collectors

main content

In the microscopic world of the starting lithium battery of a motorcycle, the current collector is like a "highway" for power transmission, undertaking the core mission of collecting current, carrying active substances and optimizing energy transfer efficiency. From traditional metal foils to revolutionary composite structures, the evolution of current collectors not only drives a leap in energy density but also triggers a technological revolution in the fields of safety and lightweighting. This article will conduct an in-depth analysis of the scientific characteristics of aluminum foil and copper foil, revealing how these nanoscale materials support the powerful instantaneous burst of motorcycles.

Positive electrode current collector: The oxidation art of aluminum foil

1. Infrastructure and functional characteristics

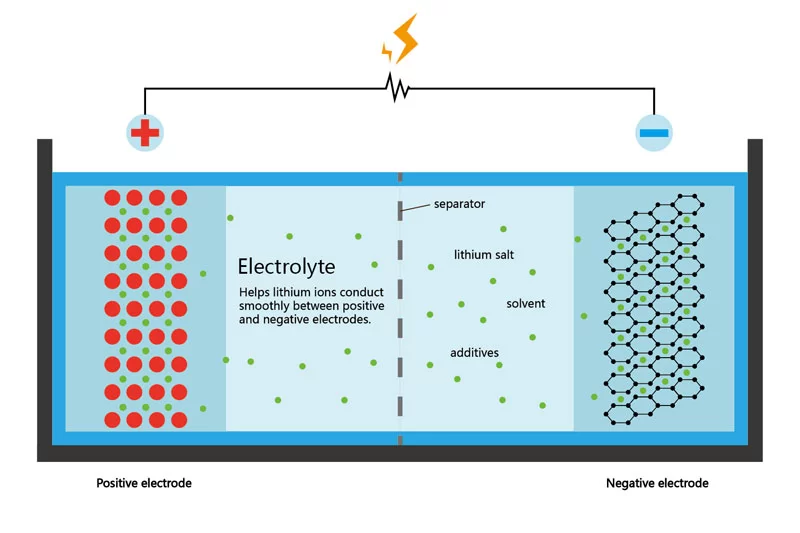

The positive electrode current collector of the motorcycle lithium battery adopts high-purity aluminum foil (with a thickness of 10-20μm), and its surface forms a dense Al₂O₃ layer (with a thickness of approximately 5-10nm) through electrochemical oxidation. This nanoscale oxide layer has three functions:

Corrosion resistance improvement: At a high potential of 4.2V, the resistance of alumina to electrolyte corrosion is three times that of pure aluminum, and the cycle life can reach more than 2,000 times.

Interface impedance optimization: The contact resistance between the oxide layer and the LiFePO₄ cathode material is reduced to 0.05Ω·cm², which is 40% lower than that of the aluminum foil without the oxide layer.

Enhanced thermal stability: In a high-temperature environment of 120℃, the alumina layer can suppress the side reactions between the aluminum substrate and the electrolyte, keeping the gas production below 0.5mL/Ah.

2. Breakthroughs in lightweight technology

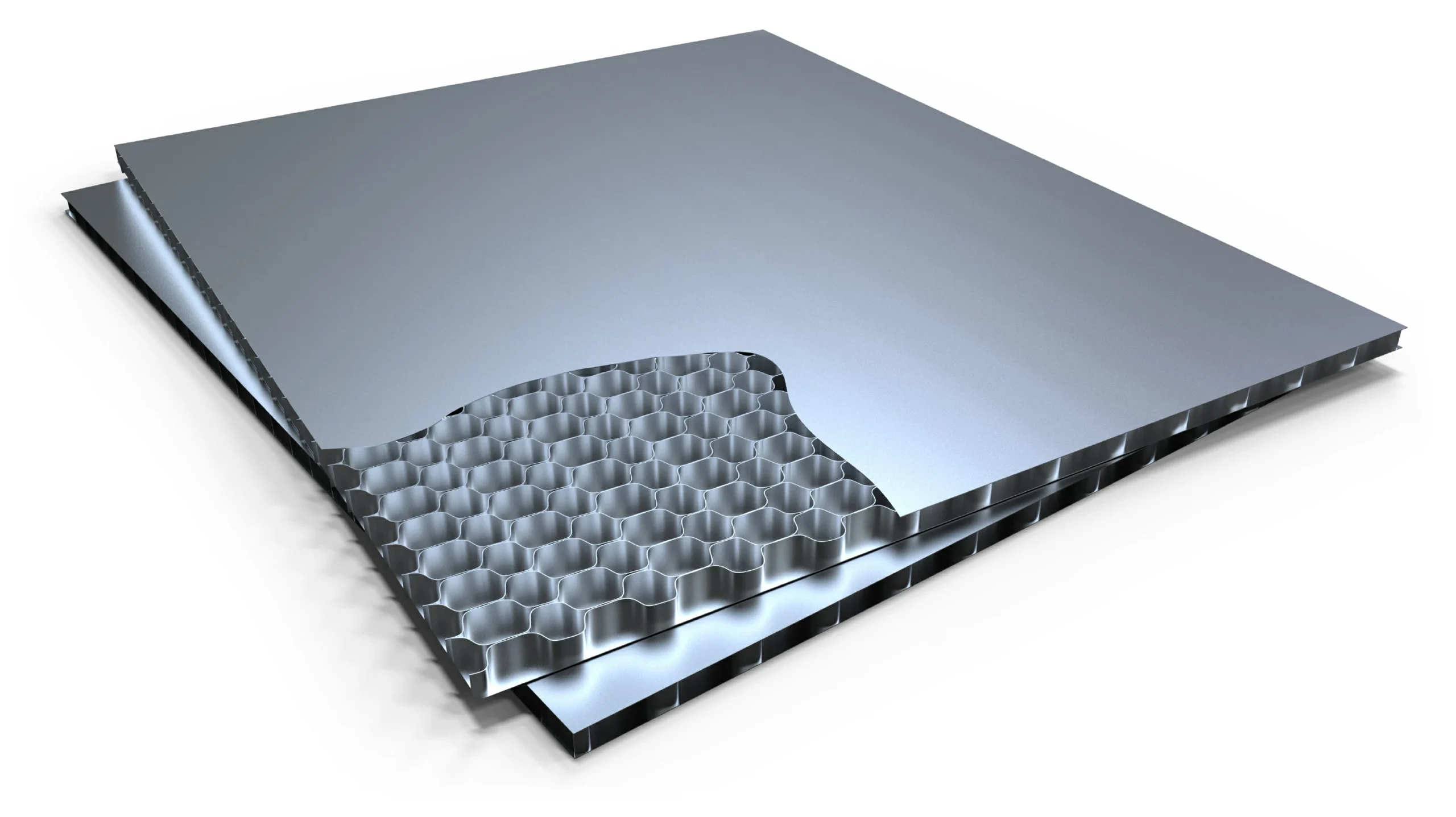

Through the innovation of the rolling process, the thickness of aluminum foil has been reduced from the traditional 16μm to 8μm, and the surface density has been decreased from 43g/m² to 22g/m². By adopting the gradient annealing technology, the tensile strength of the aluminum foil is increased to 180MPa, while the elongation is maintained at 15%.

Negative Electrode Current Collector: The Conductive Philosophy of Copper Foil

1.Microstructure design

The negative electrode copper foil (with a thickness of 6-12μm) forms a "double-sided hair" structure through electrolytic deposition:

Surface roughness control: Rz value (at ten point height) 3-5μm, specific surface area increases by 30%, and the adhesion of graphite anode is enhanced to 2.5N/cm;

Grain orientation optimization: The proportion of < 220 > crystal planes is increased to 85%, the electron mobility is as high as 5.8×10⁷ S/m, and the resistivity is < 0.1Ω·cm.

2. Breakthrough in ductility

The alloy copper foil with 0.1% silver nanoparticles added still maintains an elongation rate of 12% at a low temperature of -30℃, meeting the technical requirement that the negative electrode expansion rate is less than 8% during the cold start of motorcycles.

Conclusion

From the oxidation wisdom of aluminum foil to the cross-border integration of composite current collectors, the current collector technology of motorcycle starting batteries is reshaping the physical boundaries of energy transmission. When a 6μm composite copper foil carries an instantaneous current of 300A/cm², and when the PET base film triggers an intelligent circuit breaker at the moment of needle puncture, these nanoscale innovations are writing a brand-new chapter for the power revolution of two-wheeled motor vehicles.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!