Introduction to Battery Cell

main content

The motorcycle starting lithium battery cell is the core part of the whole battery system, and its design and performance directly affect the starting efficiency, safety and service life of the motorcycle. The following is a detailed introduction to the motorcycle starting lithium battery cell:

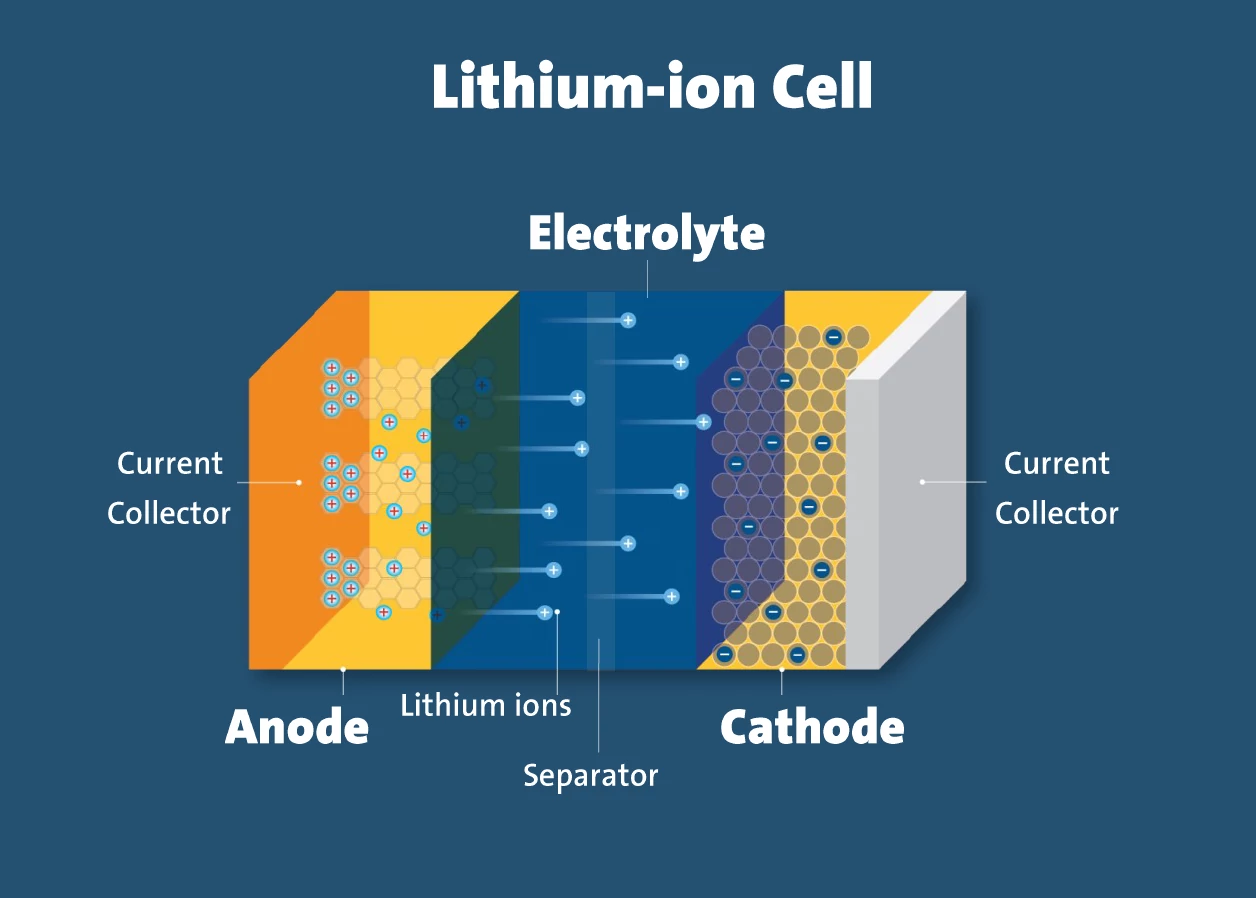

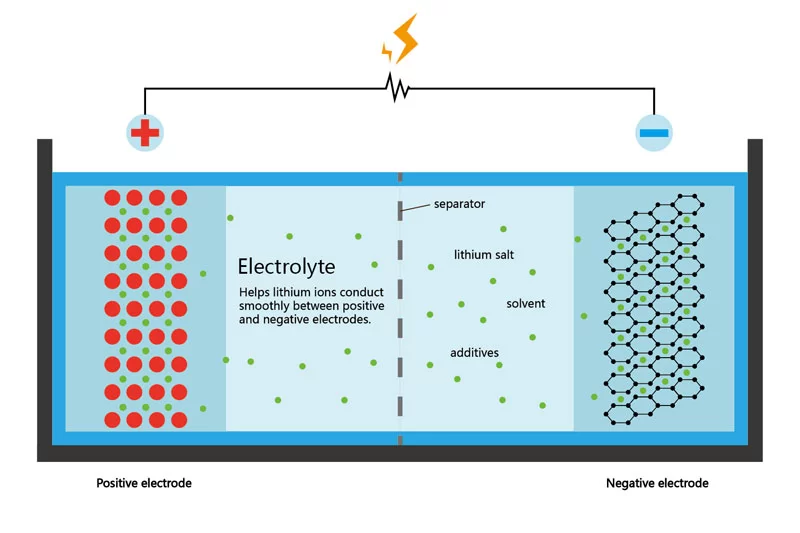

The motorcycle starting lithium battery cell is mainly composed of positive electrode, negative electrode, diaphragm and electrolyte. These components are charged and discharged by the migration of lithium ions between the positive and negative electrodes. The positive electrode is usually made of lithium iron phosphate (LiFePO4) material, which has the characteristics of high safety and long life. The negative electrode uses graphite material to provide a stable current output. The diaphragm and electrolyte are responsible for conducting lithium ions during charge and discharge, ensuring efficient operation of the battery.

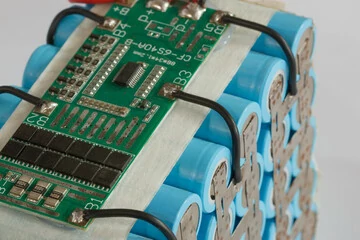

The current transmission of the motorcycle starting lithium battery cell is achieved through multiple layers of copper foil, aluminum foil and nickel tape. Copper foil and aluminum foil are used to connect the positive and negative electrodes, while nickel strips are ultrasonic welded to connect the cells in series or parallel to form a battery pack. The package structure is usually cylindrical design, which is more stable than the soft pack or square cell, and can effectively prevent the accumulation of internal pressure and bulge phenomenon, and extend the battery life.

Safety and protection devices

The motorcycle starting lithium battery cell is equipped with a variety of safety protection devices. For example, the pressure relief valve inside the cell is designed to release internal pressure in extreme circumstances and prevent an explosion. In addition, the intelligent battery management system (BMS) can monitor the voltage, current and temperature of the cell in real time, providing over-charge, over-discharge, over-mild short-circuit protection to ensure the safety and stability of the battery in various environments.

Optimized design for special scenarios

The motorcycle starting lithium battery cell is optimized for special scenarios. For example, the design of the heat dissipation hole and heat dissipation grid of the cylindrical cell can realize the heat dissipation of the upper and lower parts at the same time, improving the performance of the battery in high temperature environments. In addition, the battery also supports low temperature start function, even in a cold environment can quickly start the motorcycle. These optimizations enable the motorcycle starter lithium battery to perform well in complex road conditions and extreme weather conditions.

Conclusion

Through these core components and optimized design, the motorcycle starting lithium battery cell can not only provide efficient and stable power support, but also significantly improve the motorcycle starting performance and riding experience.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!