Safety And Environmental Considerations

main content

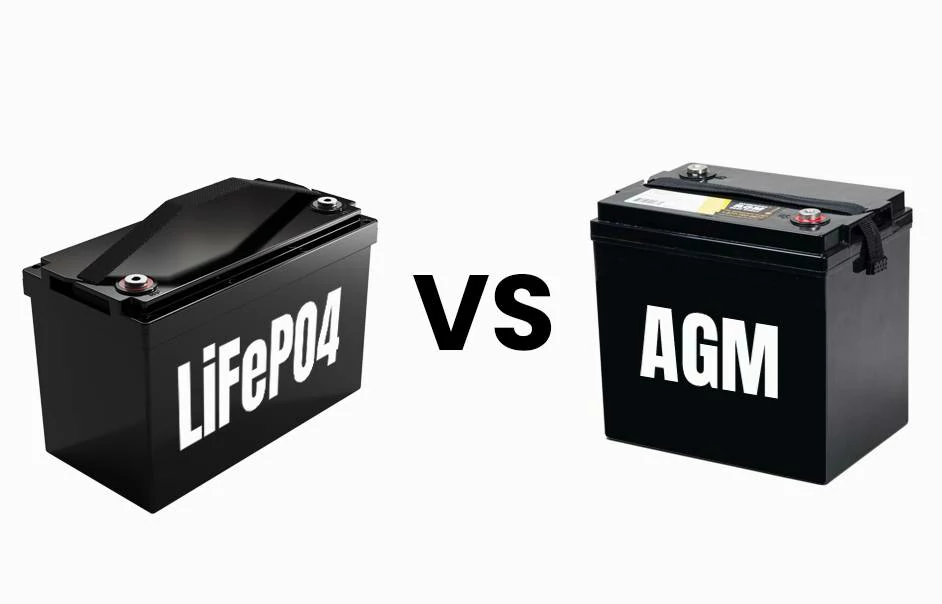

Choosing the right motorcycle starter battery involves balancing safety, environmental impact, and long-term sustainability. Lithium iron phosphate (LFP) and lead-acid batteries differ drastically in these aspects—critical factors for eco-conscious riders and manufacturers prioritizing responsible energy solutions.

Material Safety and Toxicity Risks

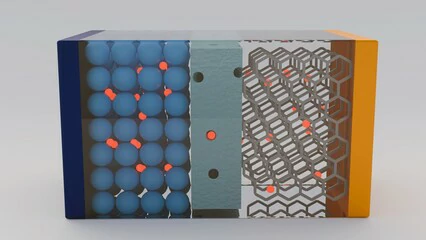

LFP batteries eliminate hazardous materials like lead and sulfuric acid, which are integral to lead-acid units. While lead-acid batteries pose risks of acid leaks and toxic fumes during overcharging or damage, LFP’s sealed design prevents electrolyte leakage even under extreme conditions. Additionally, LFP chemistry avoids thermal runaway, a rare but catastrophic failure linked to other lithium-ion variants, due to its stable iron-phosphate structure resistant to combustion below 500°C . In contrast, lead-acid batteries emit hydrogen gas during charging, requiring ventilation to mitigate explosion risks in enclosed spaces.

Recycling Efficiency and Environmental Footprint

Lead-acid batteries boast a 99% recycling rate in regions like North America, with reclaimed lead and plastic reused in new units. However, improper disposal leads to soil and water contamination from lead, a neurotoxin threatening ecosystems . LFP batteries, though recyclable, face challenges due to complex material separation and lower economic incentives. Despite this, advancements in lithium recycling technologies aim to recover over 95% of critical metals like lithium and iron, reducing reliance on mining . Notably, LFP production avoids cobalt and nickel—metals tied to unethical mining practices—making it a more sustainable choice for reducing supply chain emissions.

Operational Safety and Maintenance

LFP batteries require zero maintenance, unlike lead-acid counterparts needing regular water top-ups to combat electrolyte loss and terminal corrosion. Their built-in battery management systems (BMS) monitor voltage, temperature, and current, automatically preventing overcharging, deep discharging, and short circuits . Lead-acid batteries, lacking such safeguards, risk sulfation if stored improperly, permanently damaging capacity . Furthermore, LFP’s lightweight design reduces installation hazards, while lead-acid’s bulkiness increases handling risks during replacement or disposal.

Conclusion

Lithium iron phosphate batteries outperform lead-acid in safety and environmental sustainability, offering leak-proof operation, reduced toxicity, and compatibility with green energy initiatives. Though lead-acid recycling infrastructure remains robust, its reliance on toxic materials and higher lifecycle replacements undermine long-term eco-efficiency. For riders prioritizing safety, minimal maintenance, and lower ecological impact, LFP emerges as the forward-thinking solution.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!