BMS Fault Diagnosis Algorithms

main content

For motorcycle lithium starter batteries, BMS fault diagnosis algorithms are critical to maintaining safety, stability, and long-term performance. These algorithms act as an intelligent watchdog, identifying faults such as overcurrent, cell imbalance, or overheating before they escalate. By combining real-time monitoring with adaptive responses, BMS fault diagnosis ensures consistent power delivery, even during high-stress scenarios like cold starts or prolonged idling.

How BMS Fault Diagnosis Works

1.Continuous Parameter Tracking:

The BMS monitors voltage, temperature, current, and internal resistance across battery cells 24/7. For example, voltage deviations during charging may reveal a weak cell, while abnormal heat generation could signal a short circuit. Algorithms instantly compare these metrics to safety thresholds, initiating protective measures like charge interruption or load reduction.

2.Hybrid Diagnostic Strategies:

Physics-Driven Models: Mathematical models simulate ideal battery behavior. Deviations (e.g., unexpected voltage sag under load) help pinpoint issues like aging cells or faulty connections.

AI-Powered Pattern Recognition: Machine learning analyzes historical data to detect subtle anomalies. Neural networks classify fault types, such as distinguishing between temporary voltage dips and permanent cell damage.

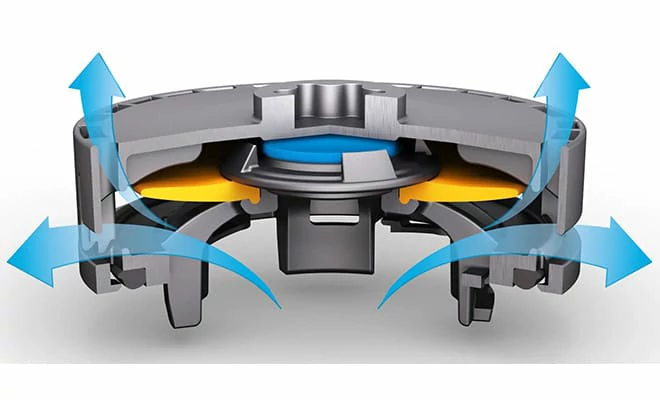

3.Dynamic Response Protocols: When a fault is confirmed, the BMS isolates problematic cells or modules to prevent system-wide damage. If a thermal runaway risk is detected, the system may activate cooling mechanisms or disconnect the battery entirely. Algorithms also adapt safety limits over time, accounting for factors like battery wear or seasonal temperature changes.

Software Layer: Turning Data into Action

The BMS software integrates diagnostics through:

Multi-Source Data Synchronization: Combining inputs from sensors to reduce false alarms and improve accuracy.

Predictive Maintenance Alerts: Flagging early signs of cell degradation or connector corrosion to enable timely repairs.

Graceful Degradation Modes: Prioritizing critical functions (e.g., ignition support) during partial failures to keep riders safe.

Why It Matters for Motorcycle Batteries

Efficient fault diagnosis extends battery life, reduces replacement costs, and prevents roadside failures. By detecting weak cells early, riders can replace individual modules instead of the entire battery. Adaptive algorithms also optimize energy output for varying loads—from high-torque starts to accessory-heavy touring setups—ensuring reliable performance in rain, heat, or freezing conditions.

Conclusion

BMS fault diagnosis algorithms represent the intersection of precision engineering and smart software, designed to meet the unique challenges of motorcycle lithium starter batteries. Through real-time vigilance and proactive fault management, these systems empower riders with confidence, safety, and uninterrupted adventures on the road.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!