Electrolyte Infiltration Physics and Chemistry

main content

Understanding electrolyte infiltration physics and chemistry is essential for optimizing lithiumion batteries, especially in demanding applications like motorcycle startstop systems. This article explains two critical aspects of the electrolyte filling process: composition design and porewetting dynamics, focusing on how they ensure safety, longevity, and vibration resistance in LiFePO4based batteries.

1. Electrolyte Composition: Balancing Conductivity and Stability

The electrolyte acts as the "blood" of lithiumion batteries, enabling ion transport between electrodes. Its formulation directly impacts thermal safety and lowtemperature performance.

SolventLithium Salt Synergy:

Motorcycle batteries often use a blend of ethylene carbonate (EC) and dimethyl carbonate (DMC) solvents. EC provides high dielectric constant for lithium salt dissociation, while DMC lowers viscosity to enhance lowtemperature fluidity. For LiFePO4 cathodes, 1.0–1.2 mol/L LiPF6 is preferred due to its balance of ionic conductivity (10⁻³–10⁻² S/cm) and thermal stability.

Additive Engineering:

Fluoroethylene carbonate (FEC) additives (3–5% wt.) form stable solidelectrolyte interphase (SEI) layers on graphite anodes. This prevents lithium dendrite growth during rapid charging and reduces gas generation under vibration—a critical feature for motorcycle batteries exposed to mechanical stress .

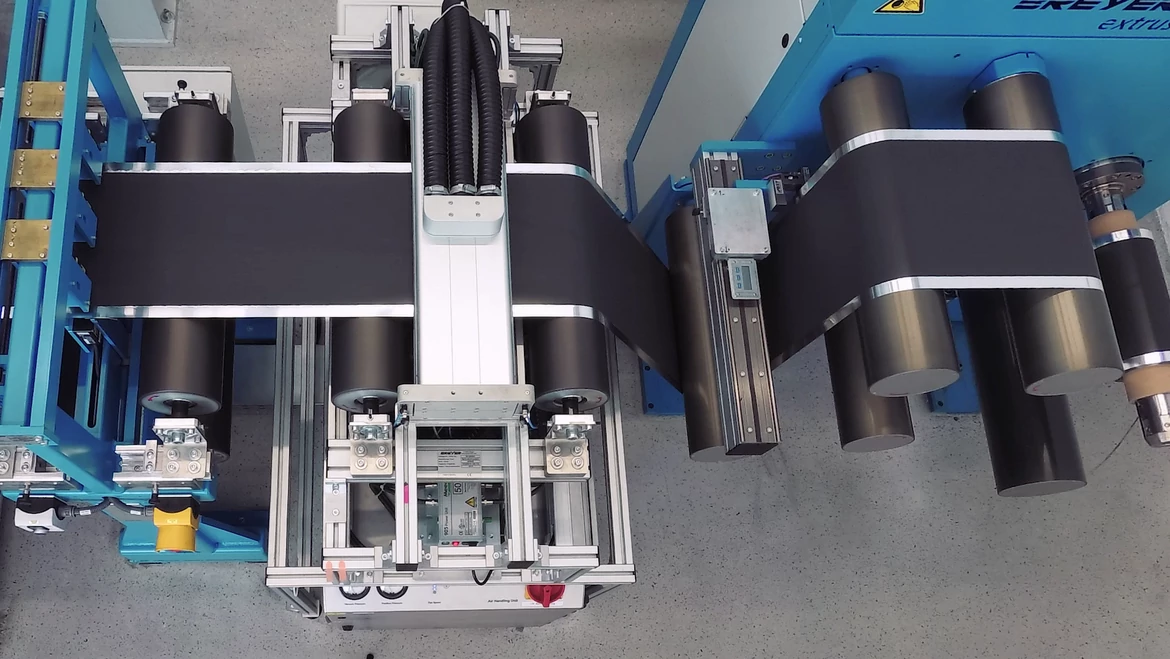

2. Infiltration Dynamics: Bridging Theory and Manufacturing

Efficient electrolyte penetration into electrode pores minimizes production delays and ensures uniform electrochemical reactions.

Washburn Equation in Practice:

The capillarydriven infiltration depth (h) follows:

\[ h = \sqrt{\frac{r \gamma \cos\theta \cdot t}{2\eta}} \]

Pore radius (r): Motorcycle battery electrodes optimize porosity (graphite: 50–60%; LiFePO4: 30–40%) to balance ion pathways and mechanical strength.

Surface tension (γ): Lowering γ via solvent mixing reduces infiltration time from 48+ hours to 12–36 hours.

Viscosity (η): DMCdominated solvents maintain η below 0.8 mPa·s at 20°C, ensuring coldclimate reliability .

VibrationResistant Design:

Highporosity graphite anodes absorb electrolyte rapidly but risk structural collapse under vibration. A graded pore structure—larger surface pores for fast wetting and smaller internal pores for stability—addresses this tradeoff. Postcalendaring processes further compress electrodes to 20–30% porosity without blocking ion channels .

Why This Matters for Motorcycle Batteries

Safety: LiFePO4’s thermal stability (decomposition >250°C) paired with FEC additives minimizes combustion risks during highcurrent starts.

Cycle Life: Optimized SEI layers and pore networks reduce capacity fade to <5% after 1,000 cycles.

Cold Performance: Lowviscosity electrolytes retain >85% capacity at 20°C, crucial for winter riding.

By aligning electrolyte chemistry with infiltration physics, manufacturers achieve batteries that meet IEC 62133 vibration standards while delivering 2,000+ deep cycles—a benchmark for modern motorcycle power systems.

RELATED BLOG

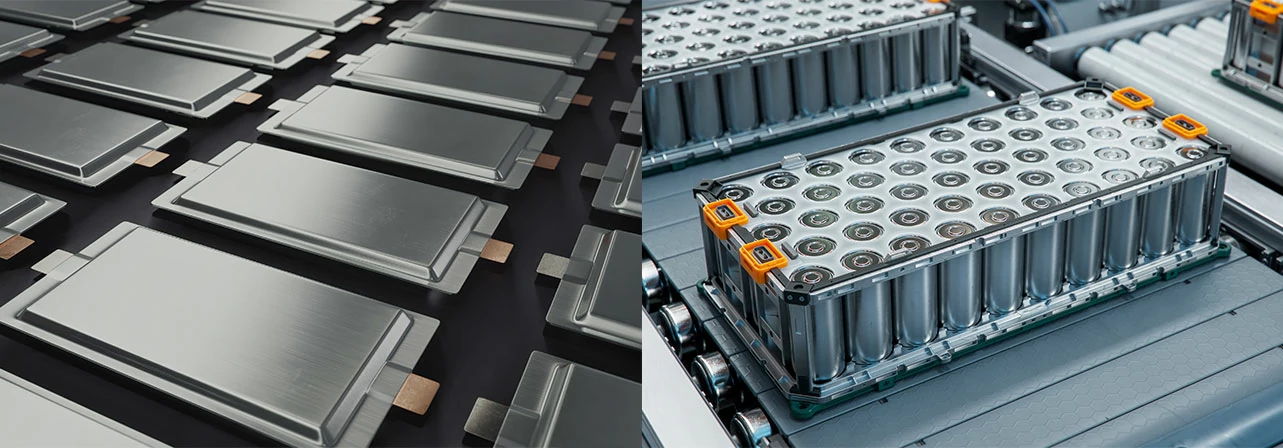

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!