Motorcycle Lithium Battery BMS SOC Estimation

main content

Motorcycle lithium battery BMS SOC (State of Charge) estimation is a cornerstone of modern battery management, ensuring riders receive uninterrupted power while safeguarding battery health. Accurate SOC calculation enables real-time monitoring of energy reserves, critical for high-performance motorcycles navigating rugged terrains or extreme temperatures. This article delves into core methodologies, challenges, and innovations in SOC estimation algorithms tailored for lithium batteries in demanding two-wheeled applications.

Core Techniques for SOC Estimation

1. Voltage-Based Methods

Open Circuit Voltage (OCV) analysis remains a foundational approach. By correlating resting voltage with charge levels after a 30-minute stabilization period, OCV provides a static reference for SOC. For instance, LiFePO4 batteries exhibit distinct voltage-SOC relationships—13.6V at 100% SOC and 10.0V at 0% SOC. While simple, this method requires precise calibration and idle time, limiting its utility during active riding.

2. Coulomb Counting

This dynamic technique integrates current flow over time to track charge depletion. Though effective for short-term accuracy, cumulative errors from sensor drift or temperature fluctuations degrade reliability. Advanced systems combine Coulomb counting with periodic OCV corrections to reset drift, balancing immediacy and long-term precision.

3. Model-Based Algorithms

Extended Kalman Filters (EKF) and adaptive observers dominate modern BMS designs. These algorithms fuse voltage, current, and temperature data with electrochemical models to predict SOC. For example, EKF adapts to nonlinear battery behaviors, compensating for aging and load variations. Hybrid models further enhance accuracy by integrating impedance measurements or machine learning-driven adjustments.

Challenges in Motorcycle Applications

Vibration-Induced Noise: High-frequency shocks disrupt sensor readings, necessitating robust signal filtering and hardware synchronization.

Temperature Extremes: Thermal fluctuations alter battery chemistry, requiring real-time compensation in SOC models.

Rapid Charge/Discharge Cycles: Aggressive acceleration or regenerative braking demands low-latency algorithms to prevent estimation lag.

To address these, next-gen BMS employ:

Adaptive Shielding: Noise-resistant current sensors and EMI-filtered voltage measurement circuits.

Multi-Layer Calibration: Temperature-dependent OCV-SOC tables and dynamic capacity adjustments.

Edge Computing: Onboard processors running lightweight AI models for real-time SOC refinement.

Innovations Driving Accuracy

1. Machine Learning Integration

Neural networks and Gaussian Process Regression (GPR) analyze historical and real-time data to predict SOC under variable loads. GPR, for instance, reduces estimation errors by 40% compared to traditional filters, excelling in non-linear scenarios like cold starts or partial charging.

2. Synchronous Voltage-Current Sampling

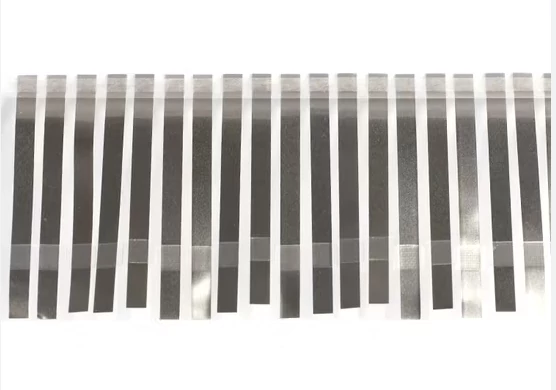

Hardware advancements enable simultaneous voltage and current measurements, improving resistance calculations. This reduces SOC drift by 25% in LiFePO4 batteries, where flat voltage curves complicate traditional methods.

3. Self-Healing Algorithms

Automatic error correction mechanisms detect sensor anomalies or model mismatches, recalibrating SOC estimates during idle periods. Such systems extend BMS reliability across 500+ charge cycles.

Conclusion

Motorcycle lithium battery BMS SOC estimation thrives on a synergy of physics-based models and data-driven innovation. From ruggedized sensors to AI-enhanced predictive analytics, these technologies ensure riders enjoy optimal power delivery while minimizing degradation risks. As electric motorcycles embrace higher voltages and faster charging, SOC algorithms will evolve into proactive guardians—anticipating failures, adapting to environments, and redefining endurance on every journey. For engineers and riders alike, mastering SOC precision isn’t just technical excellence—it’s the key to unlocking lithium batteries’ full potential.

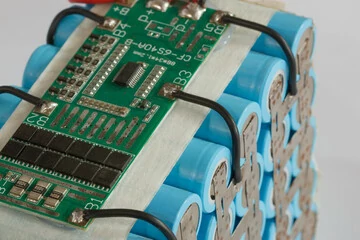

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!