Power Management Unit (PMIC) Materials

main content

The Power Management Unit (PMIC) in motorcycle lithium battery BMS systems relies on specialized materials to deliver precise energy control, thermal stability, and rugged durability. These materials are engineered to endure extreme conditions—such as vibration, moisture, and temperature fluctuations—while optimizing safety and efficiency. This article breaks down the critical materials powering modern PMICs, their roles, and emerging trends redefining electric motorcycle technology.

Essential PMIC Materials and Their Functions

1.High-Conductivity Alloys

Copper and copper-nickel alloys form the backbone of PMIC circuits, enabling low-resistance power transfer. For example, copper substrates are ideal for high-current applications like voltage regulators, while nickel-based alloys prevent corrosion in humid environments. Such materials ensure minimal energy loss in battery management systems.

2.Semiconductor Substrates: Silicon vs. GaN

Silicon dominates PMIC chip production due to affordability and scalability. However, gallium nitride (GaN) is revolutionizing high-frequency switching with its superior heat resistance and compact design benefits. This makes GaN perfect for lightweight, high-power motorcycles needing efficient energy conversion.

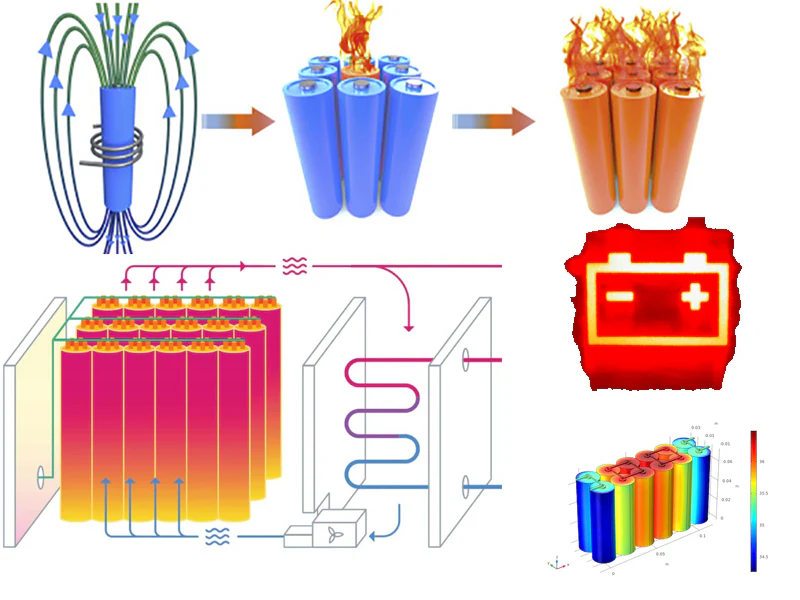

3.Advanced Thermal Management Solutions Synthetic Diamond Layers: Integrated into heat sinks, these reduce thermal resistance by 50%, critical for preventing PMIC overheating. Phase-Change Materials (PCMs): Stabilize temperature during rapid power surges, such as acceleration or regenerative braking. Ceramic Insulation: Combines electrical isolation with thermal conductivity, essential for high-voltage systems in premium motorcycles.

Durability and Compliance-Driven Innovations

1.Vibration-Resistant Polymers

Polyimide and liquid crystal polymers (LCPs) shield PMICs from mechanical stress and temperatures up to 150°C. These materials are indispensable for off-road motorcycles exposed to relentless shocks.

2.Eco-Friendly Soldering and Miniaturization

RoHS-compliant tin-silver-copper solders replace toxic lead-based alternatives. Paired with micro-interconnects, they enable compact PMIC designs that save 30% space without sacrificing performance.

3.EMI Suppression Techniques

Ferrite cores and conductive coatings neutralize electromagnetic interference from high-frequency circuits. This ensures PMICs don’t disrupt nearby sensors or communication modules in smart battery systems.

Sustainable Material Trends Shaping the Future

1.Biodegradable Encapsulation Resins

Bio-based polymers are emerging for low-power PMICs, reducing environmental impact while maintaining durability in eco-focused motorcycle models.

2.Rare-Earth-Free Magnetic Components

Soft magnetic composites (SMCs) replace rare-earth magnets in inductors, cutting costs and supporting recyclability in line with circular economy goals.

3.Graphene Thermal Interfaces

Graphene-enhanced adhesives and pads triple heat dissipation efficiency, solving thermal challenges in next-gen 800V battery architectures.

Why Material Quality Defines PMIC Success

Motorcycle BMS units demand materials that withstand harsh operating conditions. Premium PMIC materials directly impact:

Longevity: Efficient thermal management extends battery lifespan by 20%.

Safety: Flame-retardant substrates meet ISO 26262 and AEC-Q100 automotive standards.

Design Flexibility: Miniaturized components enable sleek, high-capacity battery packs.

Conclusion

Innovations in Power Management Unit (PMIC) materials are transforming motorcycle lithium battery BMS systems. From GaN semiconductors to graphene thermal solutions, these advancements address efficiency, durability, and sustainability challenges. As material science evolves, PMICs will unlock lighter, smarter, and more reliable energy management—empowering riders to push boundaries on any terrain.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!