Battery Enclosure Material Innovations

main content

Battery enclosure material innovations are redefining energy storage systems, merging durability with environmental responsibility. From aerospace-grade alloys to biodegradable polymers, modern enclosures address critical challenges like thermal runaway, corrosion, and lifecycle sustainability. Below, we analyze the transformative materials shaping next-generation battery housings.

1. Mainstream Materials: Performance-Driven Solutions

Aluminum Alloys

Lightweight and corrosion-resistant, aluminum (density: 2.7g/cm³) dominates 18650 cylindrical cell housings. However, its intrinsic softness demands ceramic composite coatings to withstand nail penetration tests at 2.5 kN force. Anodized variants achieve 15–20μm oxide layers, passing 480-hour salt spray tests for coastal applications.

Stainless Steel

316L-grade steel offers unmatched crush resistance (1,200 MPa yield strength), ideal for EV battery packs in high-vibration environments. Despite a 60% weight penalty vs. aluminum, its weldability and EMI shielding justify use in military-grade power systems.

Engineering Plastics

PA66/mPPE blends reduce weight by 30% while maintaining UL V0 flame retardancy. LG Chem’s carbon nanotube-reinforced TX5007 alloy enables 200°C-resistant motorcycle battery casings, integrating cooling channels via injection molding.

2. Cutting-Edge Breakthroughs: Future-Proof Designs

Carbon Fiber-Reinforced Polymers (CFRP)

DLFT compression molding produces monolithic CFRP housings with 5× higher specific strength than steel. Bold Valuable Technology’s aviation-grade enclosures tolerate 200°C thermal runaway, using dual-skin carbon layers for 285 Wh/kg energy density.

Bio-Based Materials

Soybean-oil polyurethane achieves 85% biodegradability without compromising IP68 seals. RoHS 2.0-compliant variants replace toxic PBDE flame retardants, aligning with EU circular economy mandates. Pilot projects show 40% lower carbon footprints vs. conventional plastics.

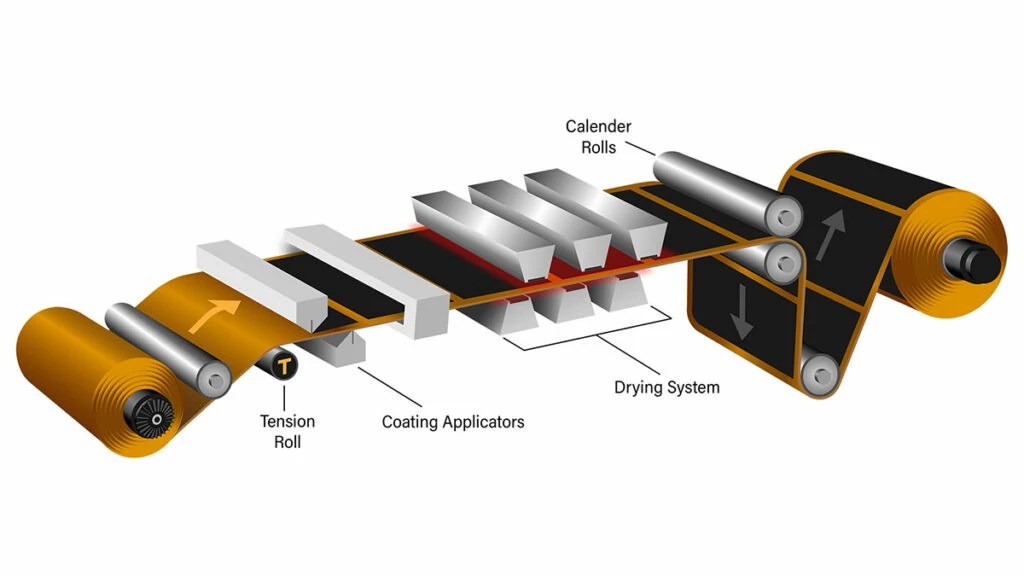

3. Manufacturing Advancements

Hybrid Molding: Engel’s PP-SABIC organosheet composites combine injection-molded ribs with 0.3mm thermoplastic layers for 25% weight savings.

3D Printing: KraussMaffei’s 20% carbon fiber/ABS prototypes validate enclosure designs 30% faster, reducing tooling costs for low-volume EV models.

Recycling: LANXESS’ PA6 housings enable 100% material recovery via single-stage compression, slashing landfill waste vs. thermoset SMC.

Conclusion

Battery enclosure material innovations bridge performance and planetary stewardship. By leveraging aerospace composites, smart manufacturing, and bio-circular polymers, next-gen housings deliver 200+℃ thermal stability, 85% biodegradability, and 40% lighter structures—empowering sustainable electrification across industries.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!