Voltage Monitoring Unit Materials in BMS

main content

The Voltage Monitoring Unit (VMU) in a lithium motorcycle battery’s Battery Management System (BMS) relies on specialized materials to ensure precise voltage measurement and long-term reliability. These materials are critical for maintaining safety, optimizing performance, and withstanding harsh operating conditions. This article examines the composition of VMU components and their role in delivering robust battery management for high-performance motorcycles.

Key Materials in Voltage Monitoring Unit Construction

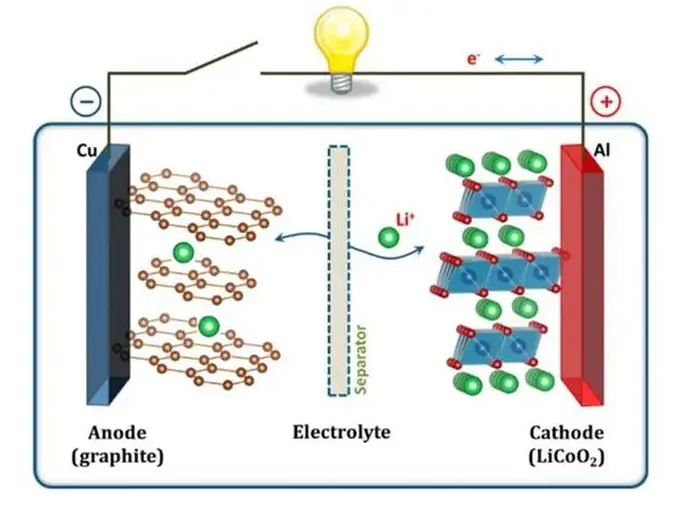

1.High-Precision Sensor Materials

Voltage sensors use thin-film resistors or advanced semiconductor alloys like nickel-chromium (NiCr) to achieve ±1–3mV accuracy. These materials provide stable resistance over temperature fluctuations (-40°C to 125°C), ensuring reliable voltage readings even during rapid motorcycle starts or extreme weather. For automotive-grade applications, sensors often incorporate gold-plated contacts to minimize corrosion and contact resistance.

2.Analog-to-Digital Converter (ADC) Substrates

ADCs utilize silicon-based integrated circuits (ICs) fabricated with low-power CMOS technology. High-resolution 12- to 16-bit ADCs feature boron-doped silicon wafers to reduce noise interference, while embedded voltage references use temperature-stable zirconium oxide layers for consistent signal conversion. These materials enable energy-efficient operation, critical for battery-powered systems.

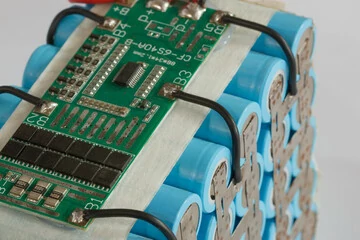

3.PCB Base Materials

The VMU’s printed circuit board (PCB) employs FR-4 epoxy laminate or ceramic-filled polyimide for thermal stability. Multi-layer designs with copper traces (1–2 oz/ft² thickness) ensure minimal signal loss. High-temperature solders, such as SAC305 (96.5% Sn, 3% Ag, 0.5% Cu), secure components to withstand vibration and thermal cycling in motorcycle environments.

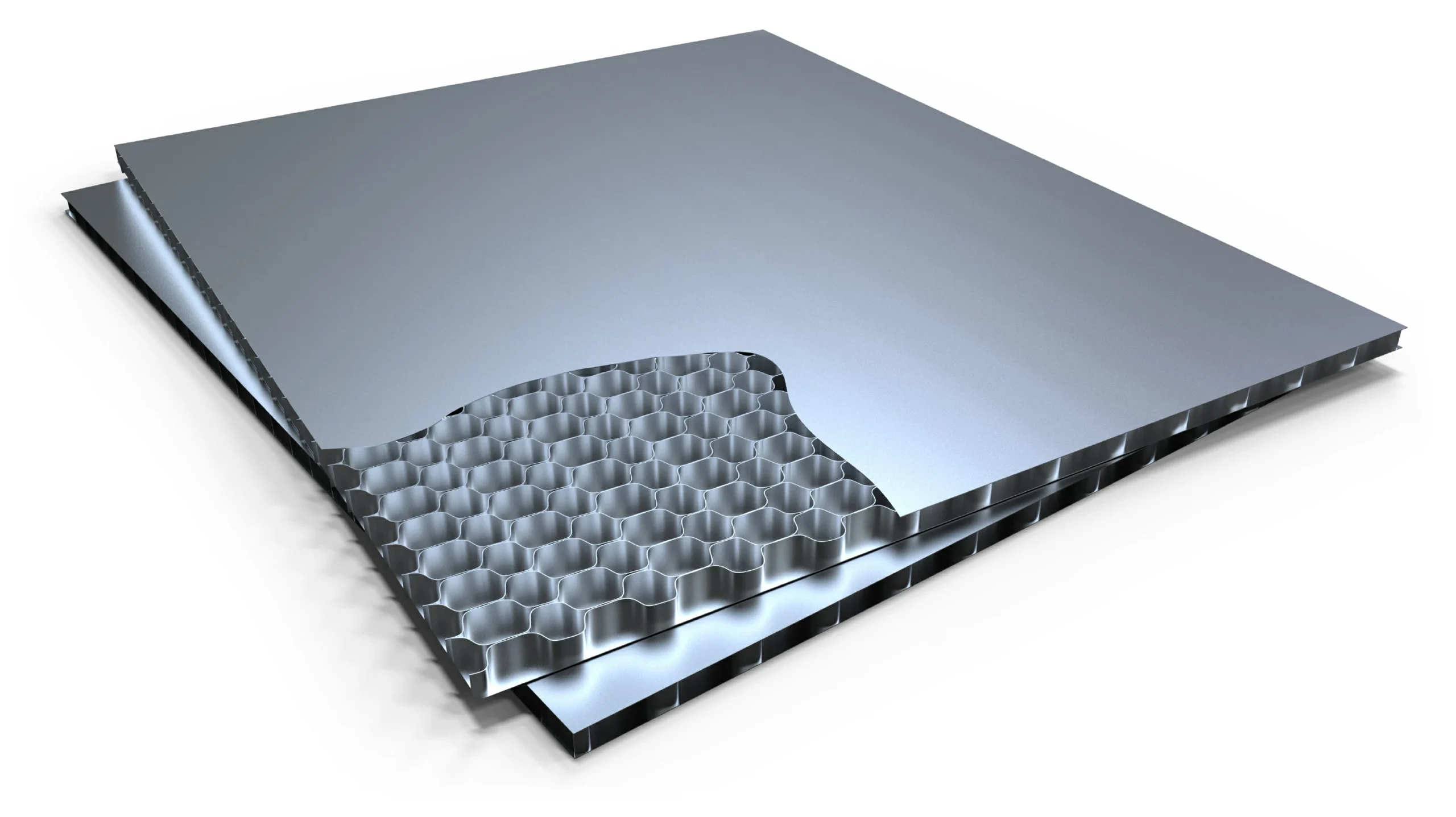

4.Isolation and Encapsulation

Galvanic isolation between high-voltage and low-voltage circuits relies on silicon dioxide (SiO₂) or polyimide films. These materials offer dielectric strengths exceeding 5kV/mm, preventing short circuits in compact battery compartments. Epoxy resins or silicone gels encapsulate sensitive components, providing moisture resistance and mechanical protection against dust and impacts.

5.Cell Balancing Components

Passive balancing circuits use thick-film resistors made from ruthenium oxide (RuO₂) for high power dissipation (up to 2W). Active balancing modules integrate MOSFETs with silicon carbide (SiC) substrates to handle rapid charge redistribution. Capacitors in these circuits feature aluminum electrolytic or tantalum-polymer materials for stable energy storage.

Material Innovations Enhancing VMU Performance

Nanocomposite Coatings: Graphene-enhanced coatings on sensor contacts reduce oxidation, extending component lifespan by 30% in humid conditions.

Low-Thermal-Expansion Alloys: Invar alloys (36% Ni, 64% Fe) in ADC packaging minimize thermal stress, maintaining calibration accuracy across temperature swings.

High-Frequency Dielectrics: Rogers 4003C laminates in PCBs improve signal integrity for high-speed communication protocols like CAN FD.

Why Material Selection Matters

Safety: SiO₂ isolation layers and flame-retardant PCB materials (UL94 V-0 rated) prevent thermal runaway risks.

Durability: Vibration-resistant solder joints and encapsulated components ensure reliable operation over 5,000+ charge cycles.

Efficiency: Low-resistance copper traces and SiC MOSFETs reduce energy losses by up to 15%, enhancing battery runtime.

Conclusion

The Voltage Monitoring Unit Materials in BMS are engineered to meet the rigorous demands of motorcycle lithium starter batteries. From precision sensors to rugged encapsulation, each material choice directly impacts safety, accuracy, and longevity. By leveraging advanced composites and semiconductor technologies, modern VMUs deliver unmatched performance in extreme conditions, ensuring riders benefit from reliable starts and extended battery life. For manufacturers, prioritizing high-quality materials is key to building BMS solutions that stand the test of time and terrain.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!