Smart Thermal Management Systems for Motorcycle Batteries

main content

Smart thermal management systems for motorcycle batteries are pivotal to maximizing performance while addressing the unique challenges of compact, high-power lithium-ion designs. By integrating advanced cooling technologies, predictive algorithms, and adaptive controls, these systems ensure optimal temperature regulation, safety, and longevity. This article explores their core mechanisms, benefits, and transformative impact on modern electric motorcycles.

1. Adaptive Cooling Technologies

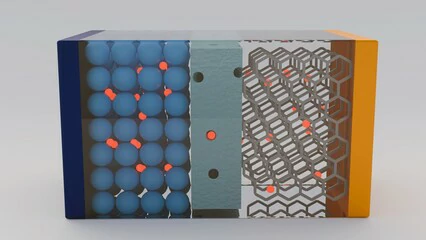

Modern thermal systems combine active and passive cooling methods to balance efficiency and space constraints. Liquid cooling, for instance, circulates coolant through microchannels embedded near battery cells, dissipating heat rapidly during high-demand scenarios like acceleration or fast charging. Meanwhile, phase change materials (PCMs) absorb excess heat passively, reducing reliance on energy-intensive components . Hybrid approaches, such as combining heat pipes with forced air, further enhance thermal uniformity without adding bulk—a critical advantage for lightweight motorcycle designs .

2. AI-Driven Predictive Controls

Smart systems leverage artificial intelligence to anticipate thermal fluctuations. Machine learning algorithms analyze historical data—such as ambient temperature, riding patterns, and battery load—to optimize cooling in real time. For example, during highway rides, the system might prioritize liquid cooling to handle sustained heat generation, whereas urban stop-and-go conditions could trigger PCM activation to conserve energy . This predictive capability minimizes overheating risks while extending battery lifespan by up to 20% .

3. Safety and Thermal Runaway Prevention

Overheating remains a critical concern for lithium-ion batteries. Advanced thermal management integrates fail-safe mechanisms like thermally conductive adhesives and flame-retardant coatings to isolate hotspots . Additionally, multi-layer sensor networks monitor individual cell temperatures, instantly triggering cooling protocols or load reduction if thresholds are exceeded. Such precision prevents thermal runaway, a key factor in battery fires, while maintaining consistent power output .

4. Modular and Scalable Designs

To accommodate diverse motorcycle models, smart systems employ modular architectures. Compact cooling plates, for instance, can be reconfigured to fit varying battery shapes, while scalable AI algorithms adapt to different pack sizes. This flexibility ensures compatibility with commuter bikes, high-performance racers, and hybrid designs without compromising efficiency .

5. Energy Efficiency and Sustainability

By minimizing energy consumption in thermal regulation, these systems enhance overall battery efficiency. Innovations like thermoelectric coolers (TECs) recycle waste heat to power auxiliary systems, reducing reliance on the main battery . Furthermore, eco-friendly coolants and recyclable phase change materials align with global sustainability goals, making them ideal for next-generation electric vehicles .

Conclusion

Smart thermal management systems for motorcycle batteries represent a leap forward in combining safety, efficiency, and adaptability. Through intelligent cooling strategies, predictive analytics, and modular designs, they address the thermal challenges inherent in high-density lithium-ion batteries. As electric motorcycles evolve, these systems will remain indispensable for delivering reliable, rider-centric performance in an increasingly eco-conscious market.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!