Lithium Motorcycle Battery Recycling System

main content

As the global demand for lithium motorcycle batteries surges, establishing an efficient lithium motorcycle battery recycling system has become pivotal to balancing performance with environmental responsibility. Transitioning from second-life applications to full circular economy models, this system addresses resource scarcity, reduces waste, and unlocks economic value while meeting stricter sustainability benchmarks.

Phase 1: Second-Life Applications – Extending Battery Utility

Lithium batteries retired from motorcycles still retain 70–80% of their capacity, making them ideal for less demanding roles. For instance, repurposed batteries can power stationary energy storage systems for small-scale solar installations or backup power units in remote areas. This second-life use delays recycling, maximizes resource efficiency, and reduces the need for new raw materials. However, challenges like standardized performance testing and safe integration into new systems require collaboration between manufacturers and recyclers.

Phase 2: Transitioning to a Circular Economy Model

A true circular economy goes beyond reuse—it regenerates materials indefinitely. Modern recycling systems now prioritize:

1.Advanced Material Recovery: Hydrometallurgical and direct recycling methods extract lithium, cobalt, and nickel with minimal energy and chemical waste. For example, selective leaching processes recover over 95% of critical metals, which are then refined into battery-grade materials for new motorcycles or other industries.

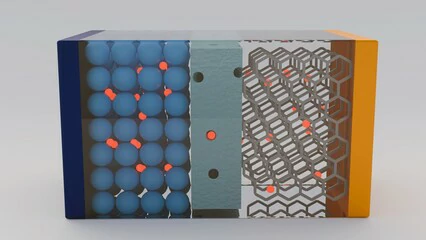

2.Closed-Loop Production: Manufacturers increasingly design batteries for disassembly, ensuring components like casings and separators are easily recyclable. Modular designs further simplify the separation of cathode materials, reducing processing costs.

3.Policy-Driven Frameworks: Regulations like the EU’s Battery Directive and EPA’s universal waste standards for lithium batteries mandate producer responsibility, incentivizing brands to invest in recycling infrastructure and consumer education.

Innovations Driving the Recycling Revolution

Technological breakthroughs are accelerating this transition:

AI-Powered Sorting: Automated systems identify battery chemistries (e.g., LiFePO4 vs. NMC) to optimize recycling workflows.

Black Mass Refining: Facilities like ABTC’s “de-manufacturing” plants convert shredded battery waste into high-purity black mass, a precursor for new battery production.

Decentralized Collection Networks: Partnerships between retailers, municipalities, and recyclers create accessible drop-off points, ensuring safer disposal and higher collection rates.

Challenges and Collaborative Solutions

Despite progress, barriers persist:

Logistical Complexity: Fragmented supply chains and varying regional regulations hinder large-scale recycling.

Economic Viability: Recycling costs often exceed mining expenses, though subsidies and carbon credit programs are narrowing this gap.

Consumer Awareness: Misconceptions about battery disposal risks, such as fire hazards, underscore the need for public campaigns.

Industry alliances like SWANA and NWRA are tackling these issues through unified policies and education. Meanwhile, startups are piloting blockchain-based tracking systems to enhance transparency across the battery lifecycle.

Conclusion

The lithium motorcycle battery recycling system is no longer an optional add-on—it’s the backbone of a greener automotive future. By integrating second-life strategies with circular economy principles, stakeholders can reduce environmental footprints, stabilize supply chains, and meet rising consumer expectations for sustainability. As technology and regulations evolve, this system will redefine how we power mobility, ensuring every battery’s journey from production to recycling aligns with planetary stewardship.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!