Lightweight Alloys and Composite Casings for Motorcycle Batteries

main content

The adoption of lightweight alloys and composite casings for motorcycle batteries is transforming the landscape of energy storage. By prioritizing weight reduction without compromising durability, these materials enable high-performance lithium batteries to deliver unmatched efficiency and longevity. This article delves into their advantages, applications, and role in advancing motorcycle battery technology.

1. Superior Weight Reduction for Enhanced Mobility

Lightweight alloys like aluminum 6061-T6 and 5083 significantly reduce battery casing mass while maintaining structural integrity. Their high strength-to-weight ratio allows motorcycles to shed excess bulk, improving acceleration and handling. Additionally, composite materials such as carbon fiber and glass fiber further optimize weight savings, enabling sleeker designs ideal for modern electric and hybrid bikes.

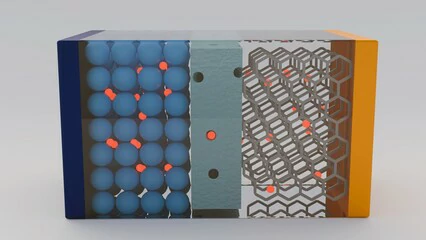

2. Thermal Management and Safety

Advanced alloys excel in dissipating heat, preventing battery overheating during rapid charging or high-speed operation. Composite casings, with their low thermal conductivity, act as insulators, shielding batteries from external temperature fluctuations. This dual approach ensures stable performance in extreme conditions, minimizing risks of thermal runaway.

3. Corrosion Resistance and Durability

Aluminum alloys naturally form protective oxide layers, combating rust and chemical degradation. Composite materials, inherently resistant to moisture and corrosive agents, extend battery lifespan even in humid or salty environments. These properties make them ideal for motorcycles exposed to diverse weather conditions.

4. Design Flexibility for Optimized Space

Composite casings can be molded into complex shapes, allowing manufacturers to maximize internal battery space while maintaining a compact footprint. Lightweight alloys, meanwhile, support seamless integration with existing motorcycle frames, reducing installation challenges.

5. Sustainability and Cost Efficiency

Recyclability is a key advantage of aluminum alloys, aligning with eco-friendly manufacturing trends. Though composite materials initially cost more, their long-term durability and reduced maintenance needs offset expenses over time.

Conclusion

Lightweight alloys and composite casings for motorcycle batteries are redefining energy storage standards. By merging weight savings, thermal stability, and robust design, they pave the way for next-generation motorcycles that prioritize efficiency, safety, and sustainability. As the industry shifts toward greener solutions, these materials will remain central to innovation, empowering riders with reliable, high-performance power sources.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!