Lifecycle Carbon Footprint Analysis Of Lithium Motorcycle Starter Batteries

main content

The global shift toward sustainable transportation has spotlighted the importance of lifecycle carbon footprint analysis of lithium motorcycle starter batteries. Unlike traditional lead-acid batteries, lithium-ion variants offer significant environmental advantages, but their true sustainability lies in evaluating emissions across production, usage, and recycling stages. This analysis reveals how innovation and policy alignment can amplify their eco-benefits while addressing lingering challenges.

Production Phase: Material Sourcing and Manufacturing Impacts

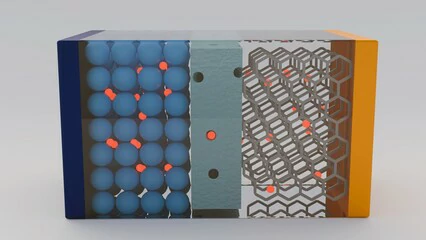

Lithium motorcycle starter batteries begin their journey with raw material extraction—primarily lithium, nickel, and cobalt. Mining these resources generates substantial emissions, particularly when sourced from carbon-intensive regions. For instance, lithium extraction in Australia or Chile often involves energy-heavy processes, contributing to 40-60% of a battery’s initial carbon footprint.

Advanced manufacturing techniques, however, are reducing this impact. Clean energy integration in production facilities, such as solar-powered refining plants, lowers emissions by up to 30%. Additionally, recycling initiatives for manufacturing scrap—like defective cells—cut virgin material demand, further shrinking the carbon footprint.

Usage Phase: Energy Efficiency and Regional Variability

During their operational lifespan, lithium motorcycle batteries excel in energy efficiency. They charge faster, retain capacity longer, and operate efficiently even in extreme temperatures. Yet, their environmental performance hinges on the energy mix used for charging. In regions like Europe, where renewables dominate, emissions drop sharply. Conversely, reliance on coal-based electricity in areas like China or India offsets these benefits.

Moreover, lithium batteries’ lightweight design reduces motorcycle energy consumption by 15-20% compared to lead-acid alternatives. This efficiency translates to fewer charging cycles and longer service life, indirectly lowering cumulative emissions.

End-of-Life Phase: Recycling and Circular Economy Potential

Recycling is pivotal to closing the sustainability loop. Traditional disposal methods risk toxic leakage, but modern hydrometallurgical processes recover over 90% of lithium, nickel, and cobalt with minimal emissions. For example, recycling a single lithium motorcycle battery can save 50 kg of CO2 equivalent compared to mining new materials.

Regulatory frameworks, such as the EU Batteries Regulation, mandate stricter recycling targets and material recovery rates, accelerating industry adoption. Emerging technologies like direct cathode regeneration further enhance efficiency, promising near-zero waste in the coming decade.

Future Trends: Innovations Driving Sustainability

The next generation of lithium motorcycle batteries prioritizes low-carbon materials and production. Solid-state batteries, for instance, eliminate flammable electrolytes while boosting energy density, reducing lifecycle emissions by 25%. Sodium-ion alternatives, though less energy-dense, offer a cheaper and more sustainable option by avoiding scarce metals like cobalt.

Manufacturers are also embracing blockchain-enabled battery passports to track carbon footprints transparently. These digital tools empower consumers to choose eco-friendly products, fostering market-driven sustainability.

Conclusion

A comprehensive lifecycle carbon footprint analysis of lithium motorcycle starter batteries underscores their transformative potential for green mobility. While challenges persist in material sourcing and recycling infrastructure, technological advancements and regulatory support are paving the way for net-zero emissions. By prioritizing circular practices and clean energy integration, the industry can ensure these batteries deliver on their promise of a cleaner, quieter, and more sustainable future.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!