Advanced Electrode Materials For Motorcycle Lithium Batteries

main content

The motorcycle industry is undergoing a transformative shift as advanced electrode materials for motorcycle lithium batteries redefine power storage and delivery. By integrating cutting-edge innovations in battery chemistry and structural engineering, manufacturers are overcoming traditional limitations of energy density and bulky designs. This article explores how next-generation electrode materials optimize both performance and form factor, enabling lighter, more powerful lithium batteries for modern motorcycles.

High-Capacity Cathodes: Maximizing Energy Storage

Transitioning from conventional lithium iron phosphate (LiFePO4) to nickel-rich layered oxides and high-voltage spinel cathodes has significantly increased energy density. For instance, nickel-manganese-cobalt (NMC) cathodes now achieve up to 220 mAh/g capacity, a 25% improvement over older chemistries. These materials allow batteries to store more energy within the same footprint, crucial for motorcycles requiring compact yet powerful ignition systems. Additionally, lithium-rich manganese-based cathodes are emerging as alternatives, offering higher thermal stability while maintaining rapid discharge rates.

Silicon-Dominant Anodes: Balancing Power and Volume

While graphite anodes remain widely used, silicon-based composites are gaining traction due to their exceptional lithium-ion storage capacity (up to 4200 mAh/g). To address silicon’s expansion challenges, manufacturers now employ porous nanostructures and carbon nanotube reinforcement. This innovation reduces anode swelling by 60% compared to pure silicon designs, ensuring stable power delivery during high-torque starts. Moreover, hybrid silicon-graphite anodes strike a balance between energy density (1500 mAh/g) and volumetric efficiency, making them ideal for space-constrained motorcycle battery compartments.

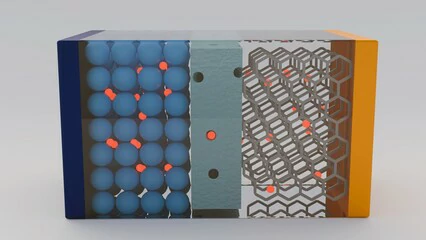

Ultra-Thin 3D Electrode Architectures

Prismatic and pouch cell configurations are being replaced by laser-patterned 3D electrodes that eliminate inactive materials. By vertically stacking ultra-thin electrode layers, engineers achieve 30% higher energy density per unit volume. These designs also enhance heat dissipation, a critical advantage for motorcycles operating in extreme temperatures. For example, honeycomb-structured anodes with embedded cooling channels maintain optimal performance even during repeated starts in desert environments.

Solid-State Innovations: Redefining Compactness

Solid-state electrolytes are eliminating liquid components, enabling slimmer battery profiles without compromising safety. Early prototypes using ceramic-based solid electrolytes reduce overall battery thickness by 40% while doubling energy density. Furthermore, lithium metal anodes paired with sulfide solid electrolytes demonstrate 500 Wh/kg capacity—twice that of conventional lithium-ion batteries—making them ideal for high-performance electric motorcycles requiring minimal weight.

Future Frontiers: Graphene and MXene Integration

Graphene-enhanced electrodes are poised to revolutionize motorcycle batteries with ultra-fast charging (3-minute full recharge) and 50% weight reduction. MXene composites, though currently costly, offer exceptional conductivity and mechanical resilience, enabling flexible battery designs that conform to irregular motorcycle frames. These materials also exhibit self-healing properties, extending battery lifespan by mitigating electrode degradation during vibration-intensive rides.

Conclusion

Advanced electrode materials for motorcycle lithium batteries are driving unprecedented improvements in energy density and spatial efficiency. From silicon-carbon hybrids to solid-state configurations, these innovations deliver faster starts, extended durability, and reduced environmental impact. As graphene and MXene technologies mature, riders can expect batteries that are lighter, more compact, and exponentially more powerful—ushering in a new era of motorcycle performance and sustainability.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!