Advanced Cathode Materials for Motorcycle Batteries

main content

The quest for lighter, more powerful motorcycle batteries is accelerating, driven by breakthroughs in advanced cathode materials that significantly boost energy density. By redefining the chemistry and structure of cathodes—the battery’s core energy source—innovators are delivering compact, lightweight lithium batteries capable of extending riding ranges while reducing weight. This evolution not only enhances performance but also aligns with global demands for sustainable, high-efficiency power solutions.

High-Nickel Cathodes: Maximizing Energy Storage

High-nickel cathode formulations, such as NMC (nickel-manganese-cobalt) and NCA (nickel-cobalt-aluminum), now dominate next-generation lithium batteries. With nickel content exceeding 80%, these materials increase energy density by up to 30% compared to traditional lithium cobalt oxide (LCO) cathodes. For motorcycles, this translates to smaller battery packs that maintain or exceed the power output of bulkier predecessors. Furthermore, optimized crystal structures minimize voltage degradation, ensuring consistent performance across thousands of charge cycles.

Cobalt-Free Alternatives: Reducing Costs and Risks

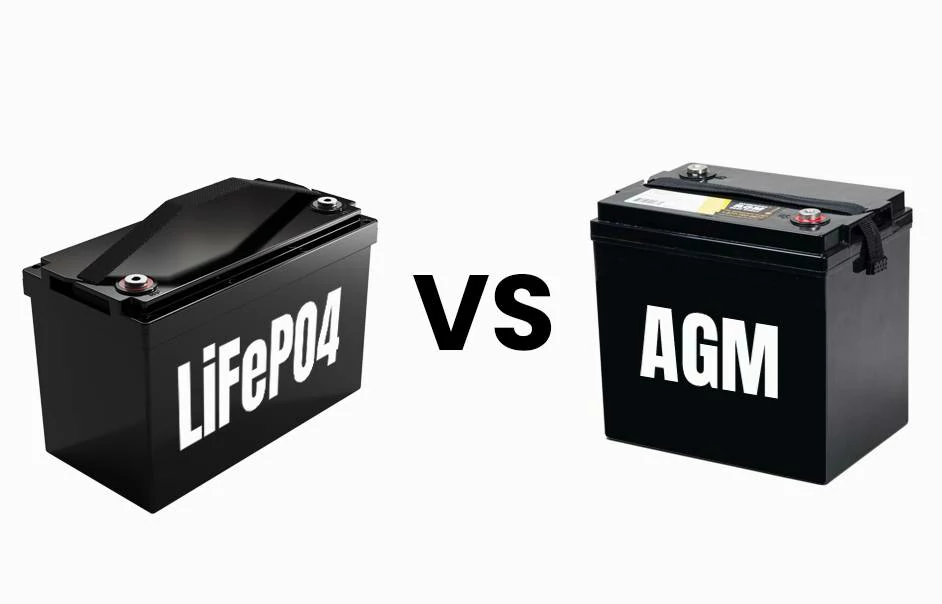

While cobalt enhances stability, its scarcity and ethical concerns have spurred the rise of cobalt-free cathodes like lithium iron phosphate (LFP) and lithium manganese iron phosphate (LMFP). LFP batteries, for instance, offer 20% higher thermal stability—a critical advantage for motorcycles exposed to extreme temperatures. Meanwhile, LMFP blends manganese’s affordability with iron’s safety, achieving energy densities comparable to mid-tier NMC at 15% lower costs. These alternatives are reshaping supply chains and enabling mass adoption in entry-level and performance bikes alike.

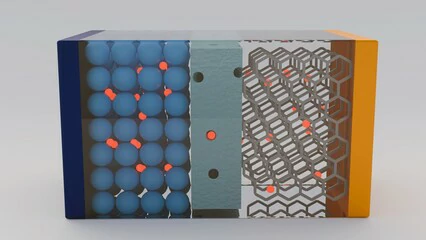

Single-Crystal Cathodes: Enhancing Longevity

Traditional polycrystalline cathodes degrade faster due to microcracks forming during cycling. Single-crystal cathode designs eliminate this flaw by using larger, unified particles that resist fracturing. Motorcycle batteries leveraging this technology demonstrate 40% slower capacity fade, even under rapid charging. Combined with silicon-carbon anodes, these cathodes enable energy densities surpassing 300 Wh/kg—enough to reduce battery weight by 25% without compromising range.

Manganese-Rich Formulations: Balancing Power and Sustainability

Manganese-based cathodes, such as lithium-manganese-rich NMC (LMR-NMC), are gaining traction for their balance of high power output and environmental benefits. Manganese’s abundance lowers raw material costs by 30%, while its stable voltage profile supports high-current discharges ideal for electric motorcycle acceleration. Additionally, manganese’s lower toxicity simplifies recycling, aligning with circular economy goals.

Solid-State Synergy: The Next Frontier

Though still emerging, solid-state electrolytes paired with advanced cathodes promise unprecedented energy density gains. By replacing flammable liquid electrolytes with solid ceramics or polymers, these systems eliminate safety risks while enabling ultra-thin cathode designs. Prototype motorcycle batteries using this combination have achieved 400 Wh/kg—double today’s commercial standards—paving the way for sub-10kg battery packs by 2030.

Supply Chain Innovations: Scaling Advanced Materials

Global cathode production is shifting toward localized, AI-driven manufacturing. Automated synthesis of high-nickel cathodes reduces defects by 90%, while AI algorithms optimize material ratios for specific motorcycle applications. Regional partnerships, particularly in North America and Europe, are accelerating the adoption of LMFP and manganese-based cathodes, ensuring stable pricing and faster time-to-market.

Conclusion

As advanced cathode materials evolve, motorcycle batteries will continue shedding weight and gaining capacity. By 2030, widespread adoption of nickel-rich and cobalt-free cathodes could reduce average battery weights by 40%, empowering riders with longer ranges and faster charging. For an industry built on agility and innovation, the cathode revolution is just hitting its stride.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!