Spot Welding for Motorcycle Start-Stop Batteries

main content

Spot welding for motorcycle start-stop batteries demands specialized engineering to address high-frequency vibration, thermal stress, and material compatibility challenges. This article delves into two critical aspects: vibration-resistant design and high-precision equipment selection, outlining how modern technologies ensure reliable performance in demanding environments.

1. Vibration-Resistant Design and Material Optimization

Motorcycle batteries endure constant mechanical stress, requiring unique structural adaptations. Here’s how advanced materials and treatments enhance durability:

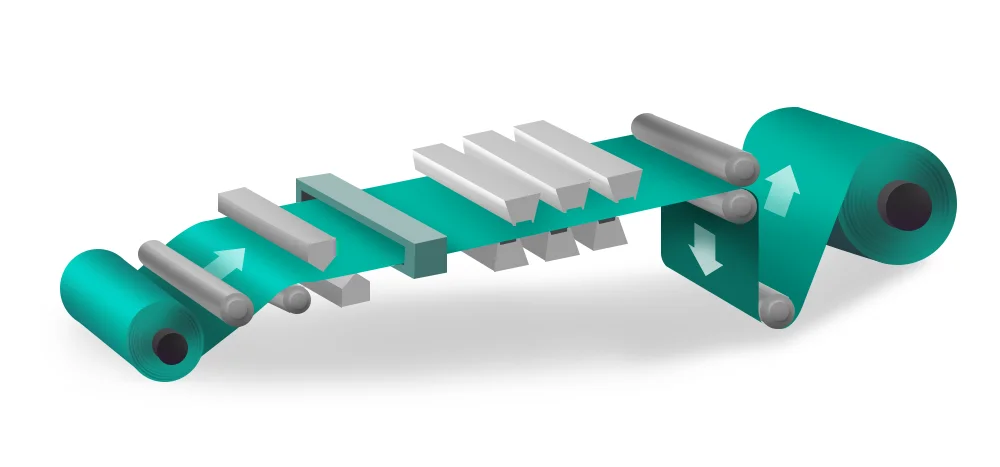

a. Nickel Strip Pre-Forming

Pre-pressed corrugated nickel strips (wave height: 0.1–0.2mm) increase contact area by 30%, reducing stress concentration during vibration. This design achieves a peel strength of ≥6 kgf, preventing joint failure under cyclic loads.

b. Electrode Surface Roughening

Laser texturing on cell tabs (Ra=3.2μm) improves frictional resistance, curbing interlayer displacement by 15%. This minimizes internal resistance fluctuations caused by thermal expansion, extending cycle life.

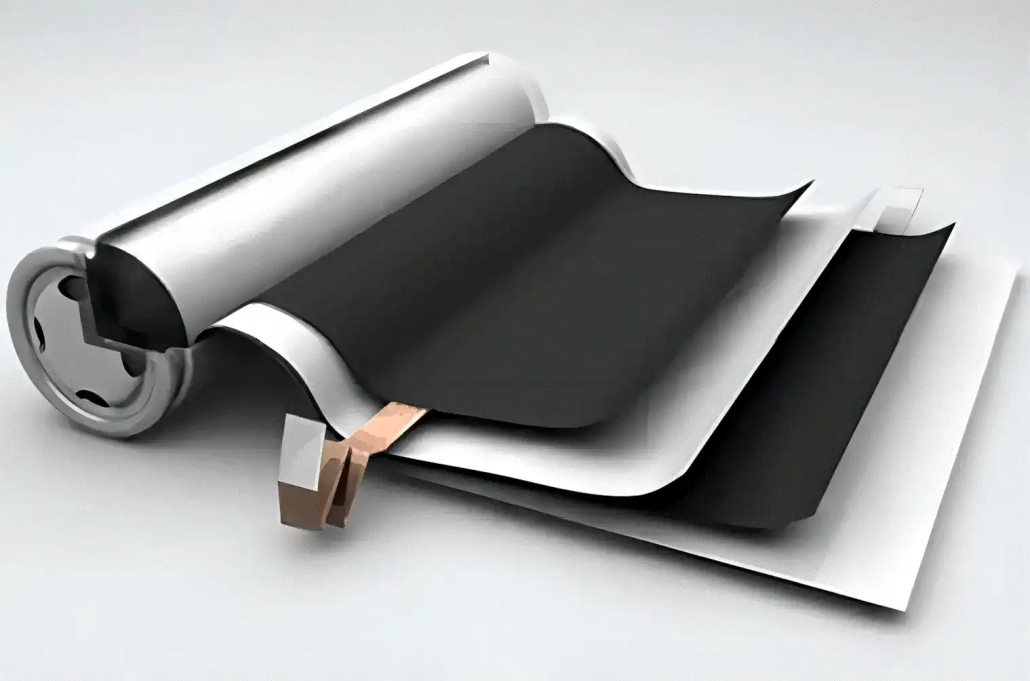

c. Hybrid Aluminum-Copper Collectors

Ultra-thin composite collectors (1μm Al + 4μm Cu) reduce weight by 60% while maintaining conductivity (≤0.5mΩ). Their layered structure absorbs mechanical shocks, preventing micro-cracks common in traditional pure-metal foils.

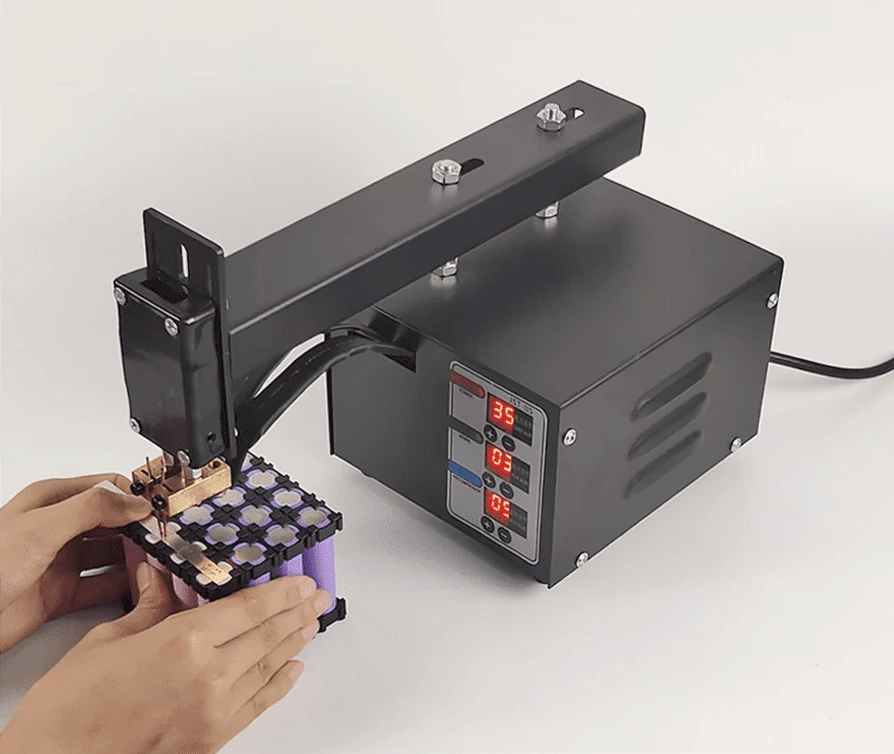

2. High-Precision Welding Systems

Precision is paramount for welding high-nickel cathodes like NCM811. Cutting-edge systems integrate automation and hybrid processes:

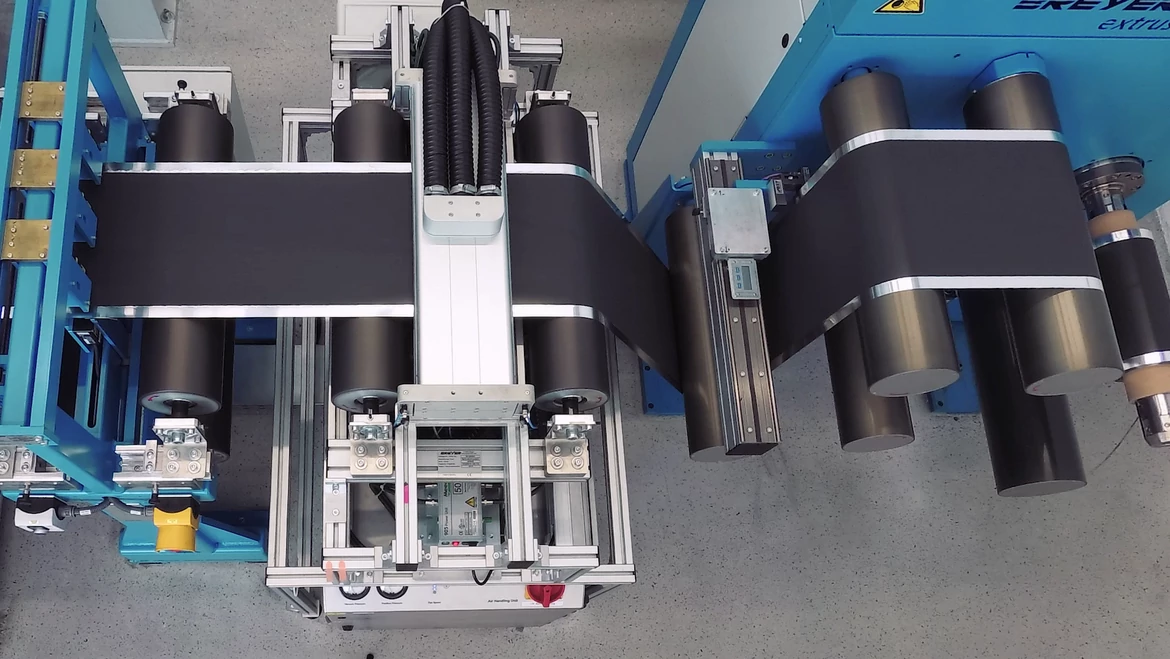

a. Automated Vision-Guided Systems

Six-axis robots paired with CCD vision (±0.05mm accuracy) enable rapid CAD path imports, slashing setup time to ≤3 minutes. For example, the BT850 welder achieves 3,600–4,000 cells/hour, ideal for mass production.

b. Laser-Resistance Hybrid Welding

A two-step process combines fiber lasers (1,064nm wavelength) and resistance welding. First, the laser removes oxide layers from high-nickel surfaces, ensuring clean interfaces.

Resistance welding then creates joints with 25% higher tensile strength than conventional methods. This hybrid approach prevents porosity and ensures stable electrical connections.

Why These Innovations Matter

Vibration Tolerance: Composite materials and surface treatments mitigate fatigue failures, crucial for off-road and heavy-duty motorcycles.

Thermal Stability: Reduced internal resistance minimizes heat generation during rapid charge/discharge cycles.

Scalability: Automated systems adapt to diverse cell formats (e.g., 26650, 32700) without compromising throughput.

For manufacturers, adopting these techniques translates to batteries that withstand 200,000+ vibration cycles while maintaining ≥95% capacity retention—key metrics for premium motorcycle applications.

RELATED BLOG

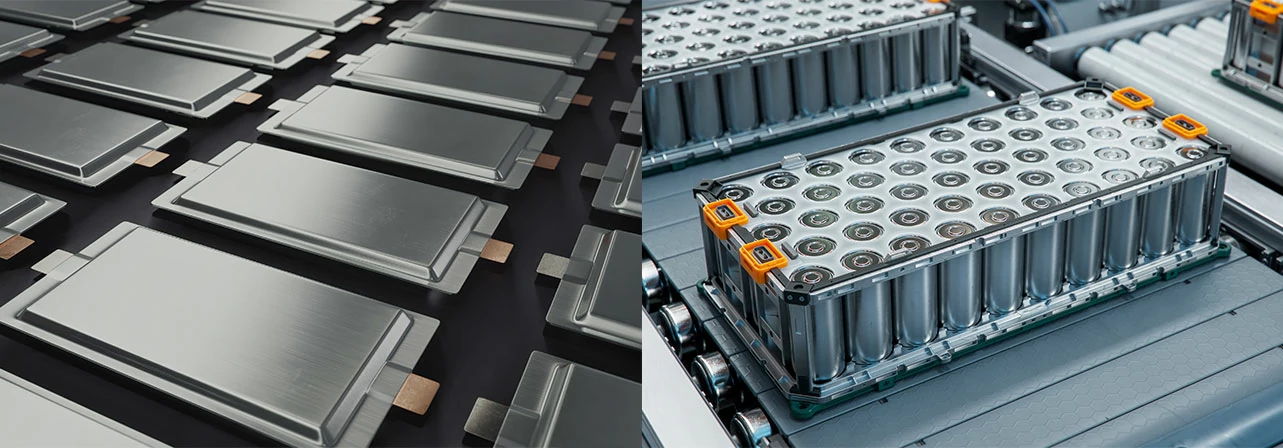

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!