Resistance Spot Welding Core Parameters

main content

Resistance spot welding core parameters—current control, pressure gradients, and electrode material selection—directly determine weld strength and consistency in battery manufacturing. By optimizing these factors, manufacturers achieve stable molten nuggets, reduced defects, and extended tool life. This guide breaks down the technical strategies behind high-performance welding systems.

1. Current Control: High-Frequency Precision

Advanced high-frequency inverter power supplies (e.g., IPG’s MDA8000A) enable ultra-precise current modulation. By alternating forward and reverse waveforms, these systems suppress spatter while stabilizing the arc. Welding time is controlled at 0.1ms intervals, ensuring molten nugget diameters exceed 3mm. For 26650 battery cells, a 210ms pulse duration with current densities of 50A/mm² creates uniform fusion zones. Such precision prevents overheating and maintains structural integrity in nickel-cathode joints.

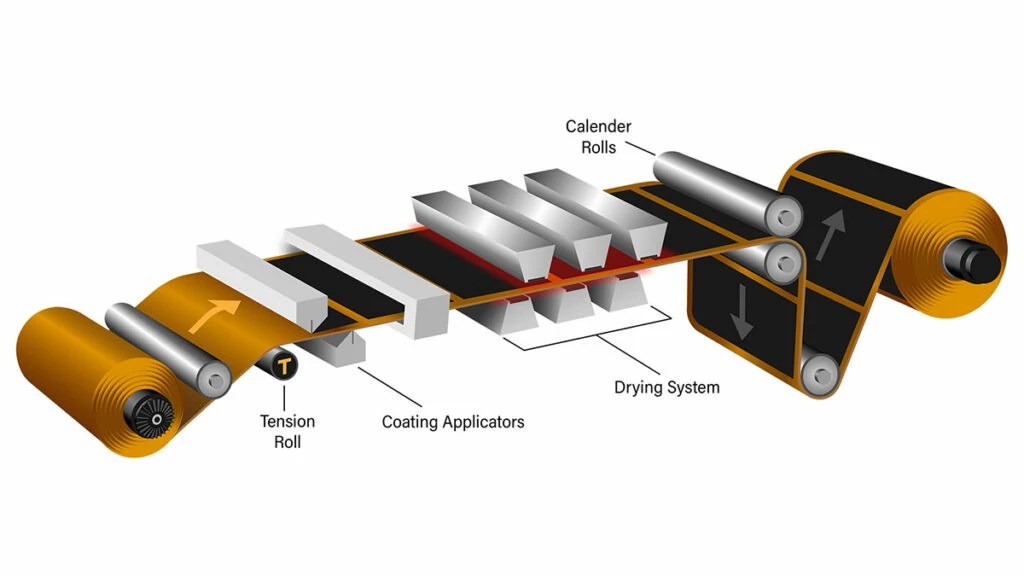

2. Pressure Gradients: Adaptive Force Management

Servo-driven electrodes apply dynamic pressure adjustments (0.3–0.6MPa) to compensate for tab deformation. A staged pressure curve optimizes contact:

Initial phase: 500N force ensures surface contact and reduces air gaps.

Nugget formation: Pressure drops to 300N to minimize stress concentrations and false welds. This adaptive approach balances heat dissipation and material flow, critical for vibration-resistant motorcycle batteries.

3. Electrode Materials: Durability & Cooling

Chrome-zirconium copper or tungsten alloy electrodes (hardness ≥180HB) withstand high thermal loads. Integrated water-cooling systems (flow rate ≥5L/min) maintain electrode temperatures below 100°C, extending service life to 100,000+ cycles. Hardened tips resist mushrooming deformation, ensuring consistent current density across production batches.

Why These Parameters Matter

Current Stability: Prevents weak joints and porosity.

Pressure Adaptability: Mitigates material warping.

Electrode Longevity: Reduces downtime and maintenance costs.

For battery packs subjected to harsh environments—like motorcycles or EVs—these parameters ensure conductivity, shear resistance, and fatigue endurance. Modern systems integrate real-time monitoring to auto-adjust settings, further enhancing reliability.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!