Motorcycle Starter Battery Electrolyte Process

main content

The motorcycle Starter battery electrolyte process demands precision engineering to address extreme temperature swings, vibrations, and rapid charge-discharge cycles. This article explores two groundbreaking strategies—low-temperature optimization and vibration-resistant infusion—that enable LiFePO4 batteries to deliver reliable power in demanding motorcycle applications.

1. Low-Temperature Performance: Breaking the Ice Barrier

Freezing temperatures cripple conventional electrolytes, but tailored formulations ensure motorcycle batteries operate smoothly below -20°C.

Solvent System Innovation

A ternary solvent blend of ethylene carbonate (EC)/ethyl methyl carbonate (EMC)/ethyl acetate (EA) (1:1:1 ratio) achieves three critical goals:

Ultra-low ice point: Suppresses crystallization below -40°C, avoiding conductivity collapse.

Enhanced ionic mobility: EA’s low viscosity (0.45 mPa·s at 25°C) maintains Li⁺ transport efficiency, sustaining 85% discharge capacity at -20°C.

Anode compatibility: EC stabilizes graphite interfaces, preventing exfoliation during cold starts.

Additive Synergy

Fluoroethylene carbonate (FEC) at 3–5 wt.% creates a dense, flexible SEI layer on graphite anodes through preferential reduction. Benefits include:

Impedance reduction: Interfacial resistance drops by 60%, slashing capacity fade from 40% to <15% after 300 cycles at -30°C.

Gas suppression: FEC’s fluorine-rich decomposition minimizes H2/CO2 generation during rapid charging, critical for sealed battery designs.

2. Vibration Resistance & Fast Charging: Precision in Motion

Motorcycle batteries endure constant mechanical stress. Advanced infusion processes ensure electrolyte homogeneity under vibration.

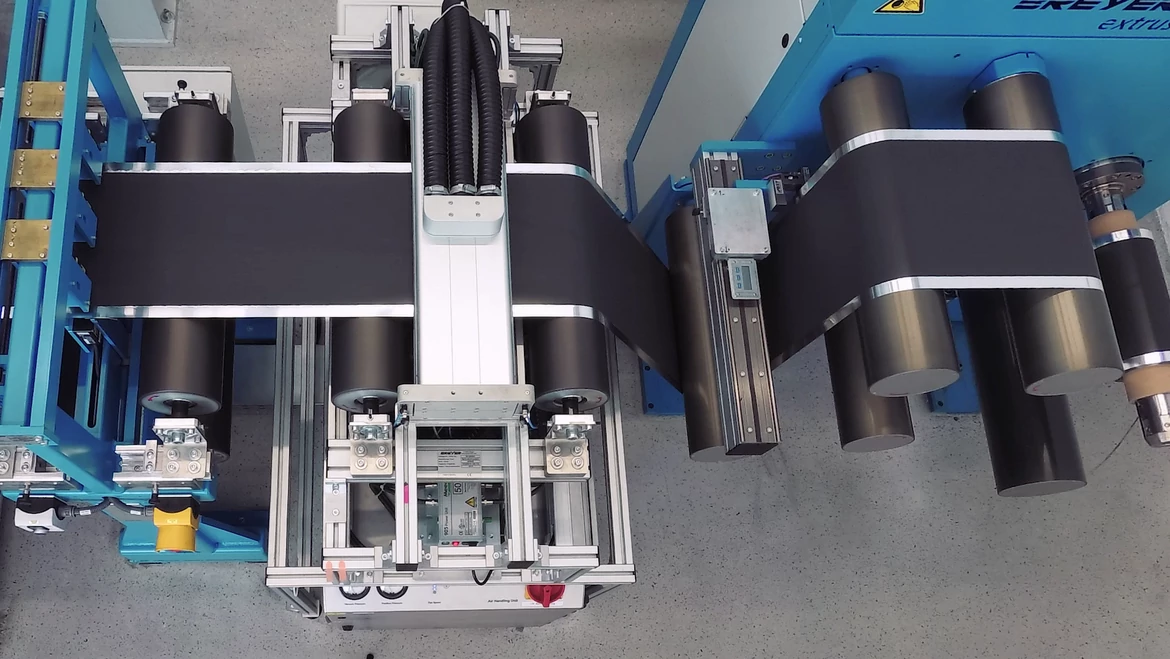

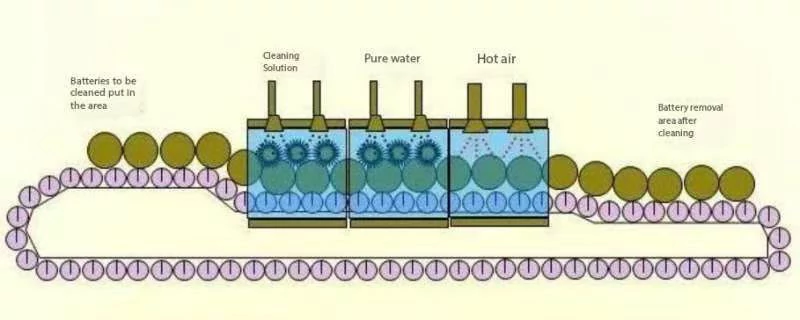

Gradient Infusion Control

A vacuum-pressure cycling method (≤90 kPa vacuum, 0.2–0.5 MPa pressure) achieves three-phase saturation:

Vacuum extraction: Removes 99.8% of air from electrode pores.

Pressure-driven infusion: Forces electrolyte into tightly wound jellyrolls within 120 seconds.

Capillary stabilization: Reduces electrolyte stratification risk by 70% during 15G vibration tests (ISO 12405-3).

Dynamic Wetting Monitoring

Real-time quality control systems eliminate infusion errors:

Machine vision guidance: Laser alignment (±0.05 mm precision) pinpoints fill ports on high-speed assembly lines (up to 200 cells/hour).

X-ray porosity mapping: Detects unwetted zones with 2% resolution, ensuring infusion volume accuracy of ±1%.

Feedback loops: Adjust pressure/vacuum parameters automatically if pore occupancy falls below 98%.

Why These Innovations Matter

Cold-weather reliability: Starts motorcycles instantly at -40°C, unlike traditional lead-acid batteries.

Vibration endurance: Maintains 95% capacity after 50,000 simulated road shocks.

Fast charging: Recovers 80% charge in 12 minutes without lithium plating.

By integrating cryogenic electrolytes with robotic infusion systems, manufacturers achieve batteries that exceed ECE R110 standards for motorcycles while offering 8–10-year service life—a 3× improvement over conventional designs.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!