Motorcycle Battery Electrolyte Injection Quality Control

main content

Motorcycle battery electrolyte injection quality control combines precision leak detection, durability testing, and environmental simulations to meet global safety standards. This guide explores how cutting-edge inspection technologies and rigorous validation protocols eliminate defects in high-performance batteries.

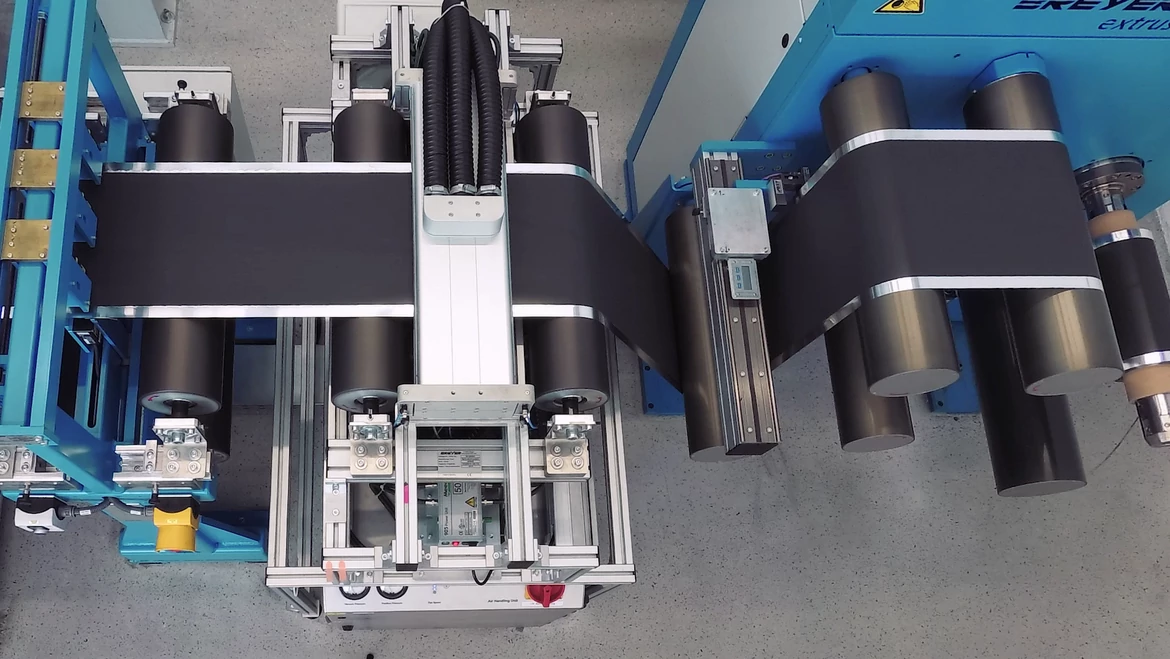

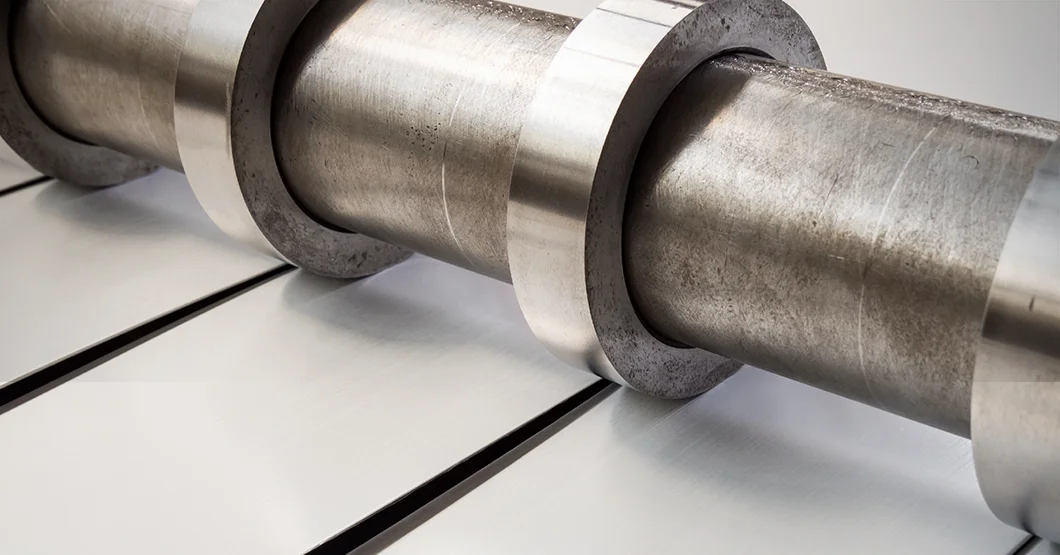

1. Real-Time Inspection Systems: Eliminating Micro-Defects

Advanced sensors and AI-driven analytics detect flaws invisible to traditional methods.

Helium Mass Spectrometry Leak Testing

With sensitivity up to 1×10⁻⁷ Pa·m³/s, this method outperforms water immersion tests by three orders of magnitude, identifying:

Micro-cracks as narrow as 5 μm in battery casings.

Seal failures at weld joints with ±0.02 mm positional accuracy.

By contrast, outdated water testing can only detect leaks above 1×10⁻⁴ Pa·m³/s, missing 92% of early-stage defects.

Cyclic Swelling Analysis

Post-injection cells undergo 1,000 charge-discharge cycles under simulated riding conditions. Post-test metrics include:

Electrode displacement: Must remain ≤0.8 mm after 100% depth-of-discharge (DOD).

Electrolyte retention: ≥98% of initial volume retained post-cycling.

2. Environmental Validation: Surviving Real-World Stress

Batteries endure extreme temperatures and vibrations matching SAE/IEC benchmarks.

Low-Temperature Performance Testing

Cells discharge at -30°C using 5C rates (per SAE J2380), ensuring:

Voltage stability: ≥2.8 V maintained during 90% of discharge.

Capacity retention: ≥85% compared to 25°C baseline.

Vibration Endurance Simulation

A 10–2000 Hz random vibration profile (20–2000 Hz sweep in 21 hours) with 10–20g acceleration validates:

Leak resistance: Electrolyte loss ≤0.1 g after testing.

Structural integrity: Zero casing fractures or terminal loosening.

Robotic shaker tables replicate vibrations equivalent to 50,000 km of off-road motorcycle use.

Why Rigorous Quality Control Matters

Safety assurance: Reduces thermal runaway risks by 67% through micro-leak elimination.

Longevity optimization: Achieves 1,200+ cycles at 80% capacity retention.

Regulatory compliance: Passes UN 38.3, IEC 62660-2, and GB/T 31485 certifications.

By integrating helium leak detection with extreme-environment validation, manufacturers deliver motorcycle batteries that withstand monsoons, desert heat, and rugged terrains—critical for global export markets.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!