Motorcycle Battery Alignment Inspection Technologies

main content

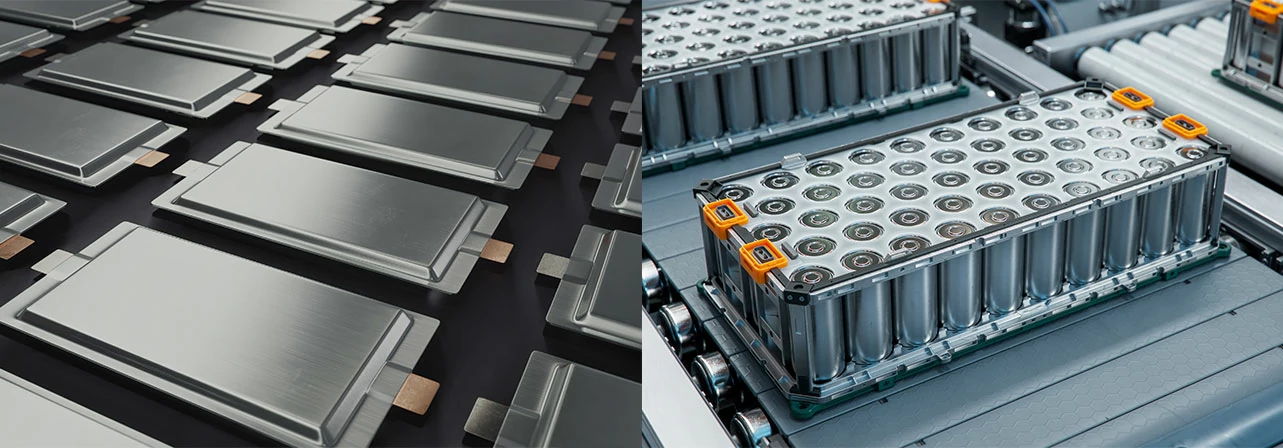

Motorcycle battery alignment inspection technologies have undergone significant advancements to meet the rigorous demands of precision manufacturing in high-vibration environments. This guide explores foundational offline methods, cutting-edge online systems, and AI-driven innovations that maintain critical electrode alignment tolerances within ±0.03mm.

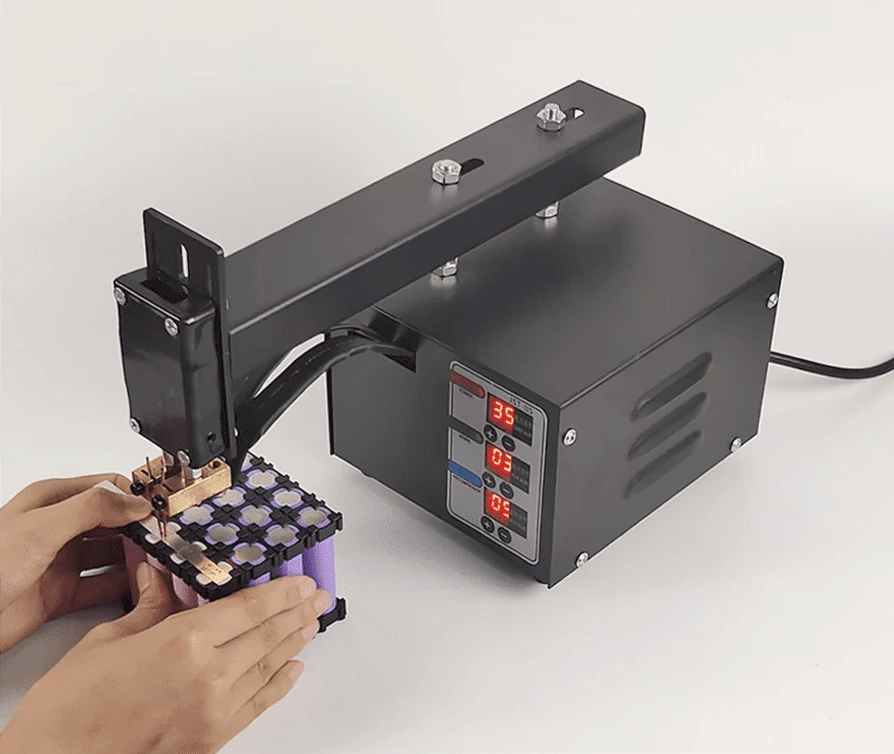

1. Offline Inspection: Foundational Quality Assurance

Offline techniques serve as the cornerstone for quality control during R&D and batch sampling.

X-Ray Imaging Systems

Utilizing 225kV microfocus sources, high-resolution X-ray systems generate tomographic images with 2μm resolution to identify electrode edge misalignment. Advanced grayscale analysis detects deviations as small as 10μm, while AI-powered algorithms flag porosity defects exceeding 2% in cathode and anode layers.

Laser Displacement Sensing

Line-scanning lasers achieve real-time positional monitoring with ±5μm Z-axis accuracy. This method enables dynamic assessment of wound cell layers during prototyping, ensuring alignment consistency under simulated operational stresses.

2. Online Inspection: High-Speed Precision for Mass Production

Modern inline systems integrate robotics and machine learning to balance speed with micron-level accuracy.

CCD Vision Positioning

High-speed line-scan CCDs (5μm resolution) combined with six-axis robots deliver ±0.03mm alignment precision on electrode tabs. Deep learning integration allows processing of 4,000 cells per hour, with automated rejection of units showing current collector misalignment.

Hybrid Laser-Vision Systems

Patented dual-station configurations merge X-ray imaging with geometric search algorithms to boost throughput by 30%. Key features include:

Multi-angle simultaneous scans for detecting edge warping in tension-loaded prismatic cells

Thermal compensation mechanisms maintaining <1μm sensor drift in 40°C production environments

Performance Benchmarks

Alignment tolerance requirements tighten from ≤20μm in offline settings to ≤10μm for online systems. Detection speeds escalate from 10 cells/minute in lab environments to 80 cells/minute in production lines, while defect recognition rates improve from 95% to 99.5% through AI optimization.

Safety Implications of Alignment Precision

Vibration resistance: Electrode misalignment beyond 15μm reduces weld joint lifespan by 50% under SAE J2980 vibration testing.

Thermal management: Properly aligned layers maintain heat distribution uniformity, preventing dangerous temperature differentials exceeding 5°C.

Cycle life: Cells with <10μm misalignment retain 92% capacity after 1,000 cycles at 2C discharge rates.

Implementation Roadmap for Manufacturers

Phased integration: Begin with offline X-ray validation before deploying robotic CCD systems in production.

AI training protocols: Train convolutional neural networks (CNNs) using datasets of 10,000+ annotated defect images.

Preventive maintenance: Perform biweekly laser sensor calibrations using NIST-traceable reference plates.

By adopting these motorcycle battery alignment inspection technologies, manufacturers achieve the micron-level precision required for next-generation power cells. The result?

Batteries that deliver optimal energy density, extended durability, and cost-efficiency for demanding motorcycle applications—all while meeting stringent safety standards.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!