Lithium Battery Formation Process: SEI Layer Dynamics and Gas Control Strategies

main content

The lithium battery formation process is a critical electrochemical activation stage that directly shapes battery performance and longevity. This guide delves into the solid electrolyte interphase (SEI) layer formation mechanisms and gas control strategies essential for highreliability batteries, particularly in highvibration applications like motorcycles.

1. SEI Layer Formation: Electrochemical Activation and Functional Impact

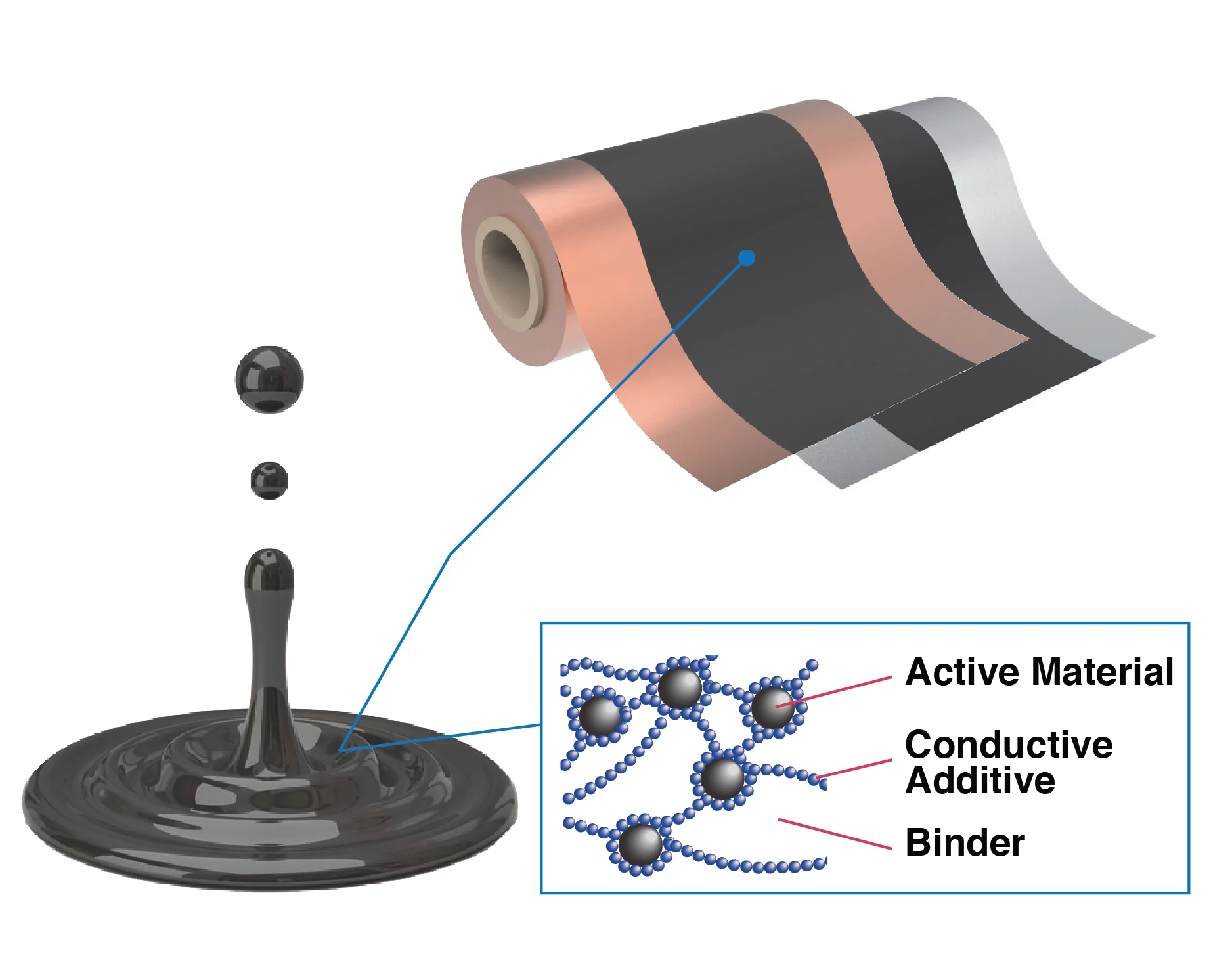

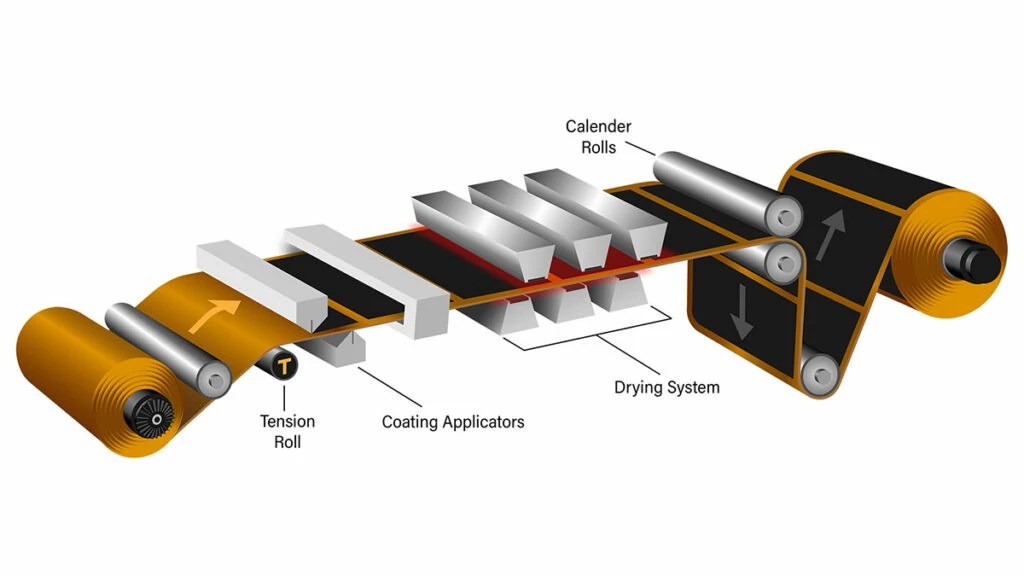

During the first charge cycle, lithium ions deintercalate from cathodes (e.g., NCM811 or LFP) and migrate to the graphite anode. Concurrently, electrolyte components (e.g., EC/DMC/EMC) undergo irreversible reduction at the anode surface, forming a 100–120 nm SEI layer. This layer comprises inorganic compounds (Li₂CO₃, LiF) and organic lithium salts (ROCO₂Li), which act as an ionconductive yet electroninsulating barrier.

Key Functions of SEI Layers

Electrolyte Stabilization: Prevents continuous solvent decomposition, reducing active lithium loss by up to 15% per cycle.

Resistance Control: Poorly formed SEI increases impedance—500 ppm moisture contamination can raise capacity loss by 0.5% due to LiF precipitation.

Cycle Life Enhancement: Stable SEI layers enable >80% capacity retention after 2,000 cycles in LiFePO₄ cells.

For motorcycle batteries, SEI uniformity is vital to withstand mechanical stress. Cracks in the SEI due to vibrations accelerate lithium dendrite growth, raising short circuit risks.

2. Gas Evolution Dynamics: Types, Risks, and Mitigation

Gas generation during formation correlates strongly with voltage thresholds and electrolyte chemistry.

Gas Types by Voltage Phase

<2.5 V: H₂ and CO₂ dominate (hydrolysis of LiPF₆ and trace water).

3.0–3.5 V: Ethylene (C₂H₄) peaks from EC decomposition, contributing to 60–70% of total gas volume.

>3.8 V: Methane (CH₄) and ethane (C₂H₆) emerge as DMC/EMC break down.

Control Strategies for HighVibration Applications

1. Staged Current Charging:

Initial 0.05C charging minimizes localized heat, reducing C₂H₄ production.

Gradual rampup to 0.2C stabilizes SEI growth while limiting gas nucleation.

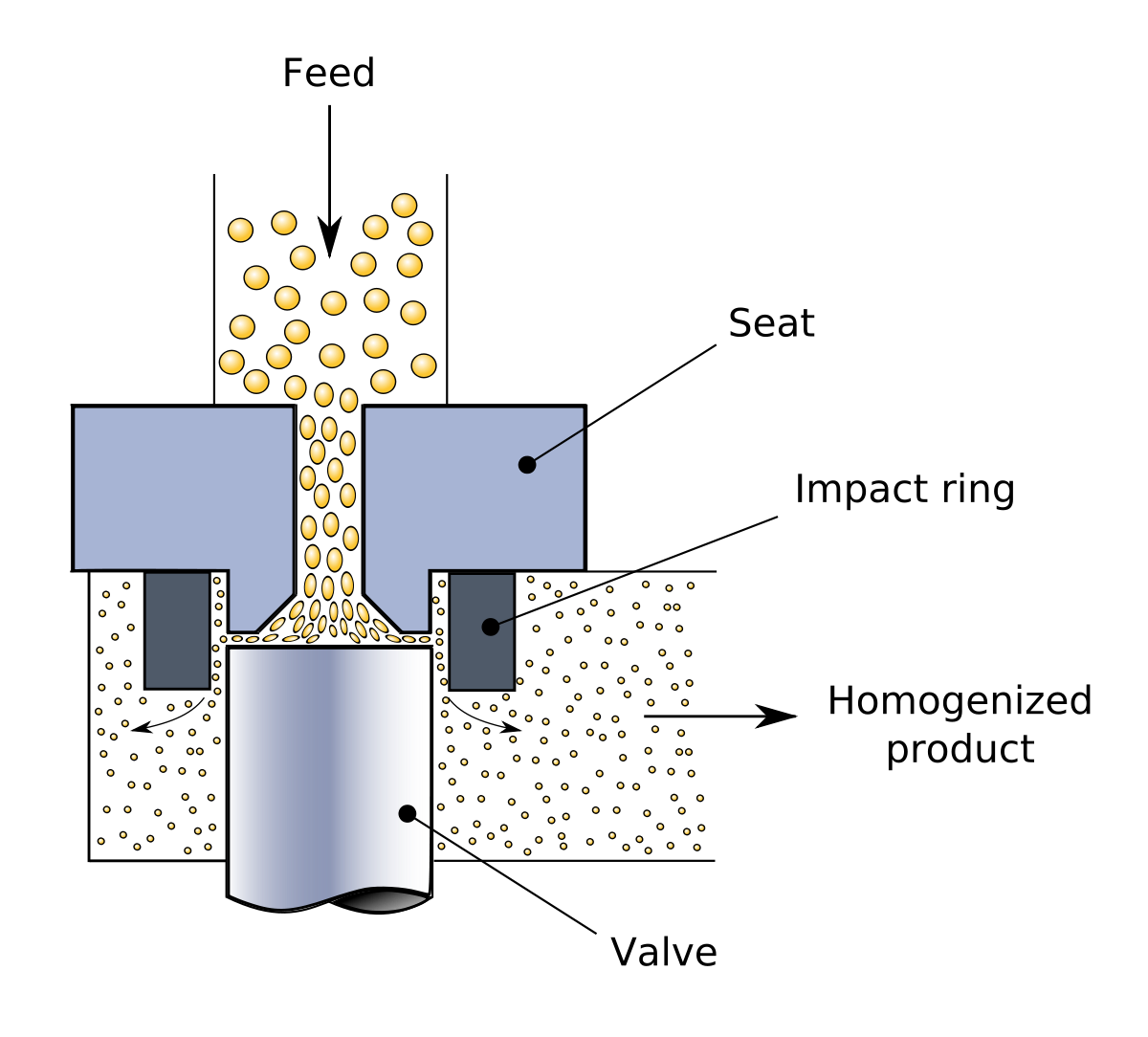

2. Vacuum Pulse Degassing:

Intermittent 95 kPa vacuum cycles remove gas pockets, curbing cell swelling below 3% volumetric expansion.

3. Electrolyte Additives:

Vinylene carbonate (VC) reinforces SEI organic layers, suppressing EC decomposition and C₂H₄ emissions by 40%.

Advanced Process Design for Motorcycle Batteries

MultiStage Formation Protocols

1. PreConditioning:

24hour electrolyte soaking ensures pore infiltration, reducing moisturetriggered H₂ generation.

2. Temperature Modulation:

Maintaining 25–30°C balances SEI growth kinetics and gas solubility, avoiding Li plating.

3. RealTime Monitoring:

Pressure sensors detect abnormal gas accumulation, triggering emergency venting.

PostFormation Quality Metrics

SEI Thickness: ≤120 nm (measured via cryoTEM).

Ionic Conductivity: ≥1×10⁻⁴ S/cm (electrochemical impedance spectroscopy).

Gas Residuals: <0.5% volume fraction (GCMS analysis).

Why Precision Matters in Battery Formation

Optimizing the lithium battery formation process achieves:

Safety Compliance: ISO 124054compliant SEI layers prevent thermal runaway below 150°C.

Cost Efficiency: Automated degassing cuts rework rates by 18–22%.

Performance Consistency: Tight gas control ensures ≤0.3 mV/d selfdischarge in motorcycle batteries.

By integrating electrochemical modeling and adaptive process controls, manufacturers can tailor SEI structures and gas management for extreme operating environments—ensuring durability in highvibration, highpower applications.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!