Lithium Battery Alignment Accuracy

main content

Lithium battery alignment accuracy directly determines energy output, cycle life, and safety, particularly in highvibration applications like motorcycle batteries. This guide explores structural precision requirements, manufacturing error cascades, and mitigation strategies for missioncritical battery systems.

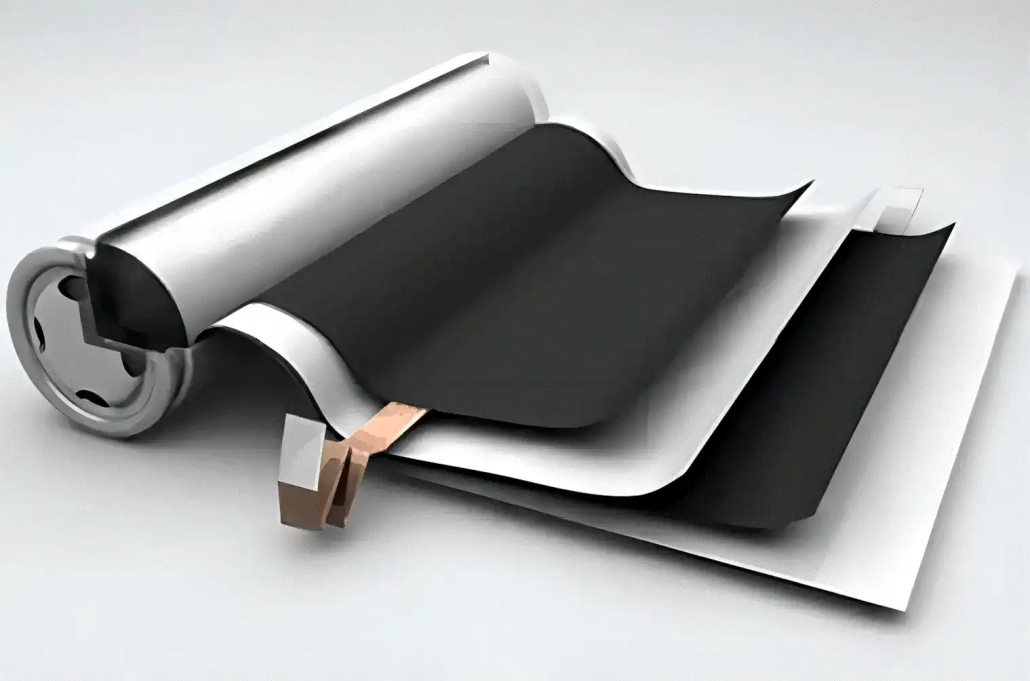

1. Structural Precision: Why MicronLevel Alignment Matters

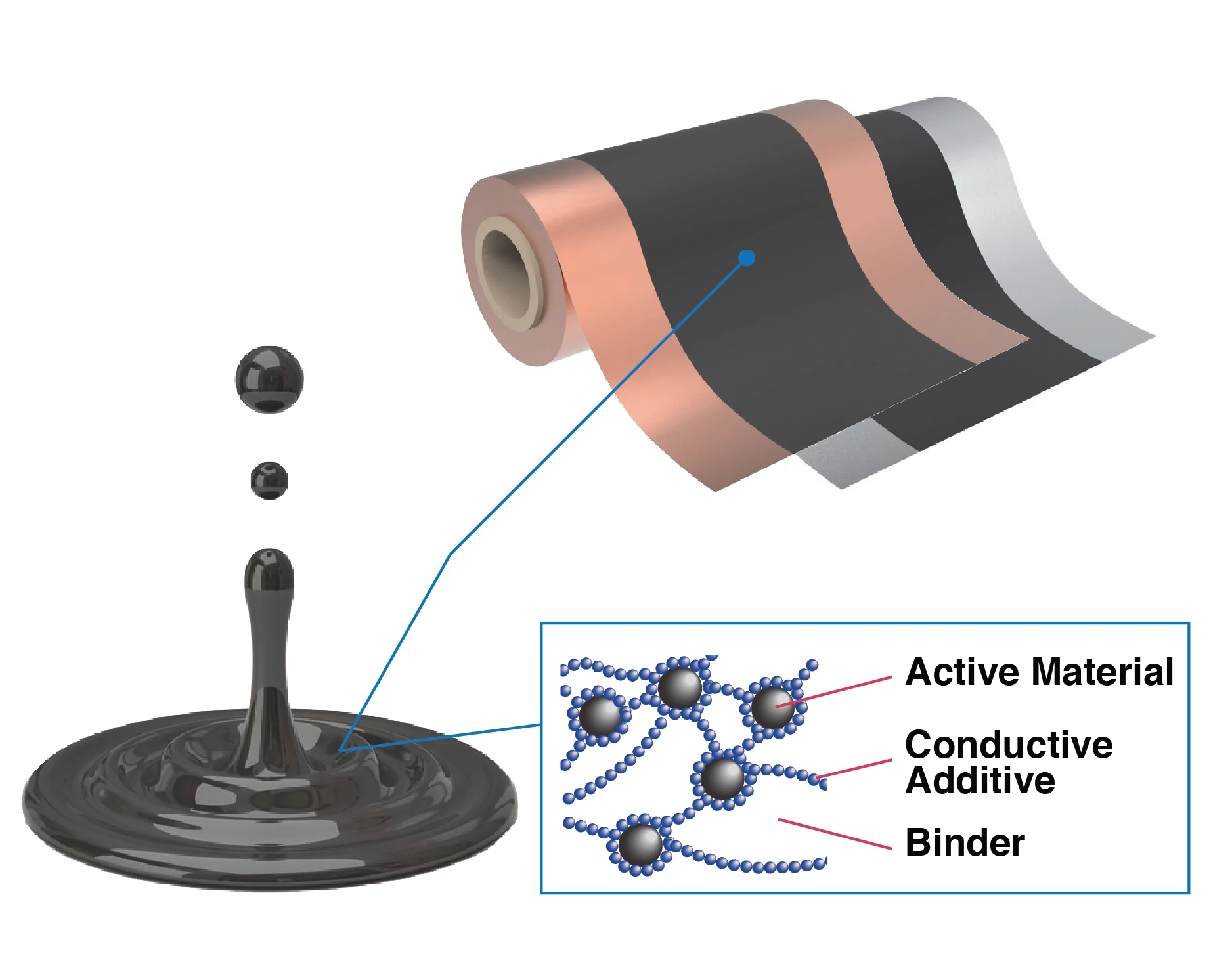

Accurate electrode alignment ensures uniform ion flow and minimizes parasitic reactions. However, deviations exceeding tolerance thresholds trigger irreversible performance degradation.

Critical Alignment Parameters & Risks

Active material overlap: Full overlap between anode/cathode active zones maximizes capacity utilization. A 1mm misalignment reduces effective contact area by 5%, directly lowering energy density .

Tab positioning: Tabs (current collectors) must align within ±0.1mm under vibration. Motorcycle batteries endure 10–20Hz random vibrations (10–20g acceleration), causing tab displacementinduced separator abrasion and microshorts when misalignment exceeds 100μm .

Edge safety margins: Misaligned electrodes expose sharp edges, increasing puncture risks. At ≥200μm misalignment, separator penetration probability triples during nail penetration tests .

VibrationSpecific Failure Modes

Cyclic fatigue: Repeated lateral shifts create microtears in separators, accelerating electrolyte dryout.

Current collector fracture: Tab misalignment concentrates stress at weld joints, reducing connection strength by ≥18% after 5,000 vibration cycles .

2. Manufacturing Error Cascades: From Tolerance Stacking to Systemic Failures

Alignment inaccuracies compound across three core processes, demanding tighterthanstandard controls.

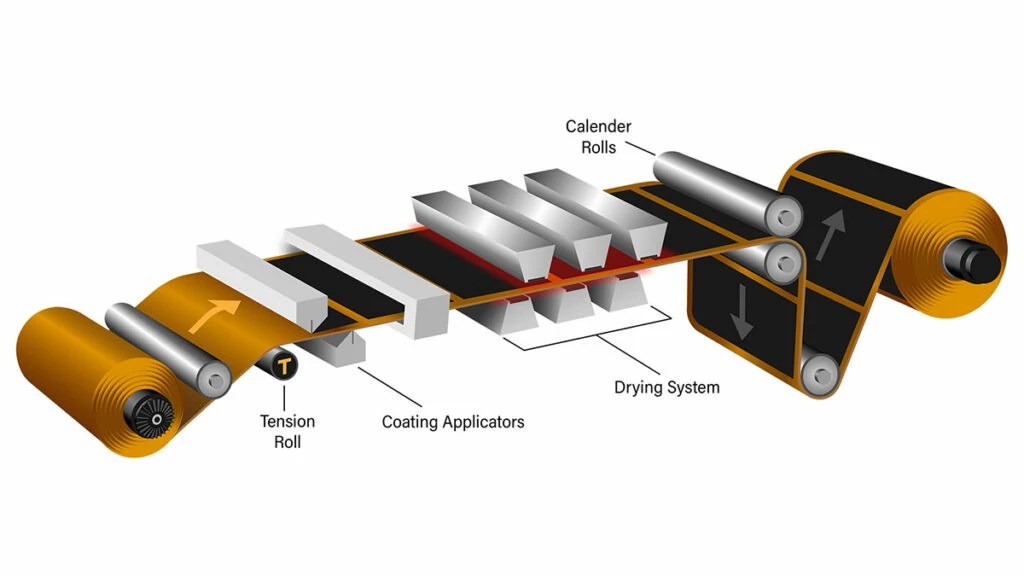

ProcessSpecific Error Contributors

1. Notching precision

±0.1mm tab spacing errors accumulate to 7mm cumulative deviation after 50 winding layers .

Solution: Laser notching with <±30μm repeatability replaces mechanical dies, reducing burrs by 60% .

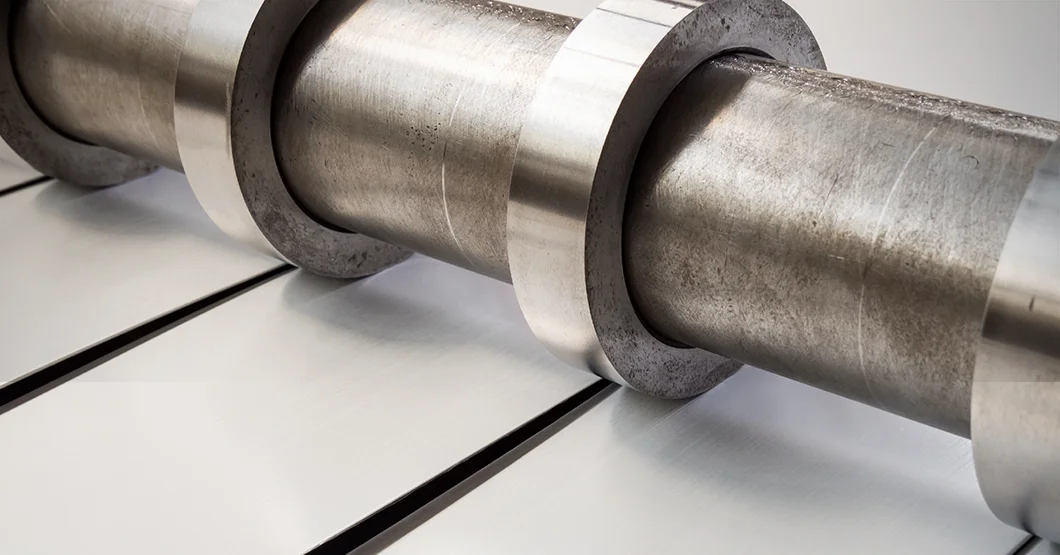

2. Winding tension gradients

>±5% tension variation induces electrode slippage, creating ≥0.3mm edge misalignment per winding cycle .

Advanced control: Realtime tension feedback systems maintain ±1.5% tolerance via servodriven rollers .

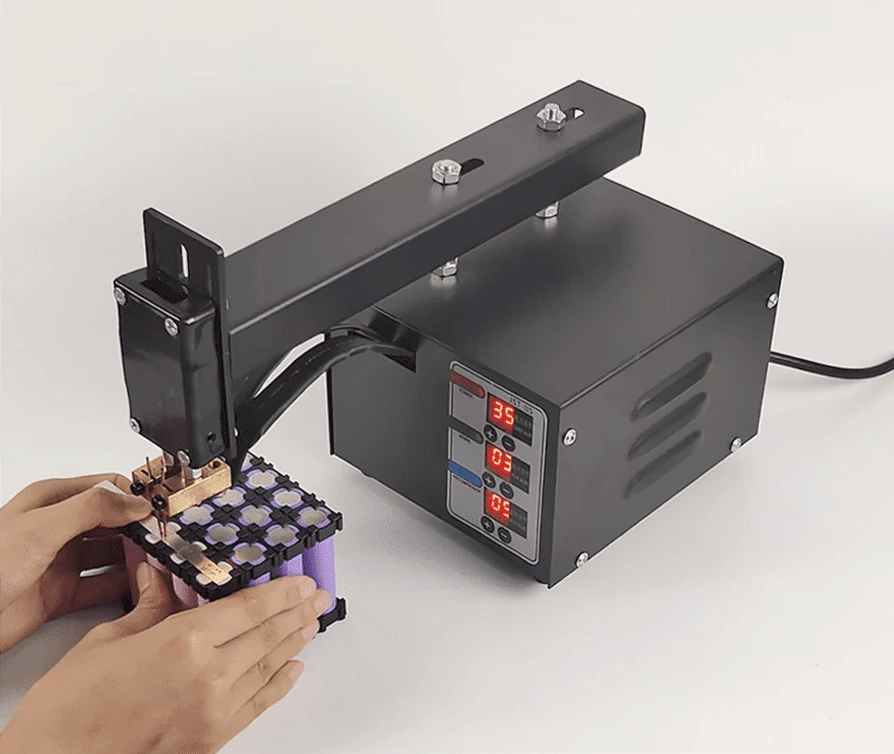

3. Stacking robotic accuracy

<±0.05mm robotic arm positioning is mandatory for Zfold stacking. Visionguided systems achieve ±0.02mm precision using CCD alignment markers .

Mitigation Strategies for HighReliability Batteries

Process Optimization Techniques

Inline metrology: Laser profilometers measure electrode positions every 0.5s during winding/stacking, triggering autocorrection if deviations exceed 50μm .

Anisotropic adhesives: UVcured adhesives with >80% shear strength retention under vibration lock electrode layers without impeding ion transport .

Multistage sorting: Presort electrodes by dimensional tolerance (±20μm) before assembly, minimizing mismatchinduced stress .

Validation Protocols

Xray computed tomography (CT): Detects ≥25μm internal misalignments nondestructively .

Vibration aging tests: Simulate 10year motorcycle service loads via 20–200Hz sweep cycles while monitoring impedance drift .

Why Alignment Precision Defines NextGen Battery Success

Cost reduction: ≤0.1mm alignment cuts scrap rates by 22% in highspeed production .

Safety compliance: Meets UN38.3 vibration standards with <0.01% thermal runaway probability .

Energy density: Precisionaligned cells achieve ≥5% higher volumetric density versus industry averages .

By integrating closedloop process controls and advanced material engineering, manufacturers can overcome alignmentrelated failure modes—ensuring lithium batteries withstand extreme mechanical and electrical demands while maximizing lifecycle ROI.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!