Drying Storage Physicochemical Mechanisms

main content

Drying storage physicochemical mechanisms are critical for safeguarding motorcycle batteries against waterinduced degradation. This guide explains how moisture attacks battery components, explores diffusionbased drying models, and outlines industryproven solutions for moisture control in compact, highpower cells.

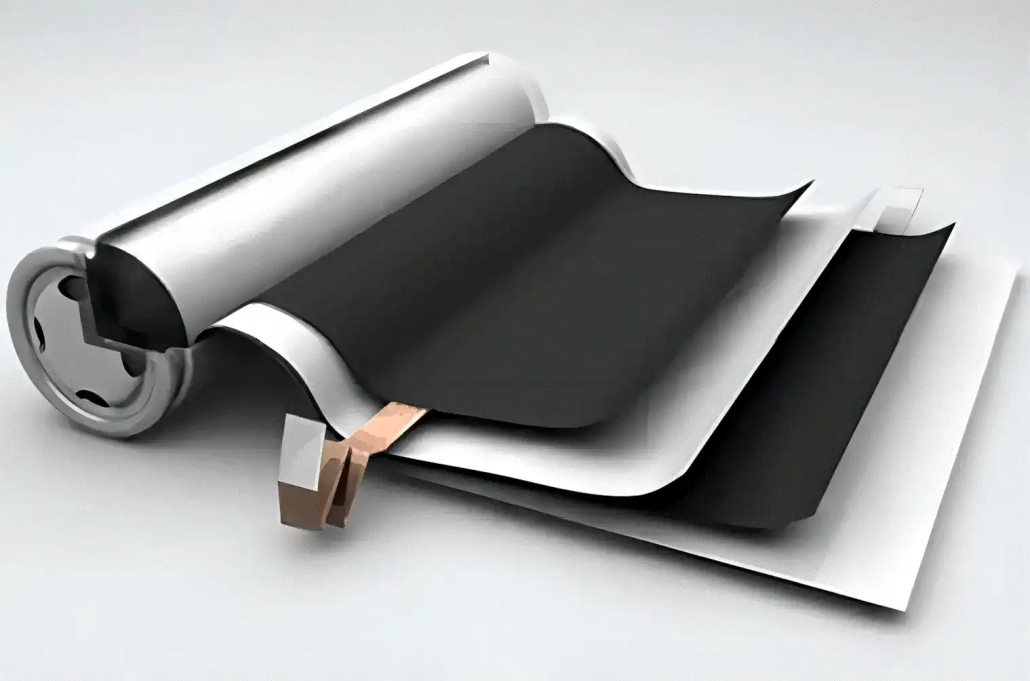

1. Moisture Damage Pathways: How Water Destroys Battery Performance

Even minimal moisture exposure triggers irreversible electrochemical reactions, particularly in highnickel cathodes and graphite anodes.

Key Degradation Processes

Cathode oxidation: Water reacts with NCM811 cathodes, forming lithium hydroxide (LiOH) and lithium carbonate (Li₂CO₃). Every 500 ppm H₂O reduces capacity by 0.5% and increases swelling by 15–30% during cycling.

Electrolyte breakdown: Moisture reacts with LiPF₆ salt, generating hydrofluoric acid (HF). At ≥100 ppm HF, the SEI layer dissolves, causing graphite anode peeling and 20–50 mΩ resistance spikes.

Separator failure: Absorbed water lowers the thermal shutdown temperature of PE/PP separators by 5–10°C, raising shortcircuit risks during hightemperature operation.

MotorcycleSpecific Risks

Frequent vibration and rapid temperature changes accelerate moisture damage:

Case corrosion: Aluminum battery casings develop microcracks, enabling humidity ingress.

Gas pressure buildup: Li₂CO₃ formation during cycling strains welded seals, risking electrolyte leaks.

2. Drying Kinetics: Optimizing Moisture Removal

Effective drying relies on controlling heat, pressure, and diffusion rates to achieve ultralow humidity levels.

Fick’s Second Law Application

Moisture diffusion follows:

\[ \frac{\partial C}{\partial t} = D \frac{\partial^2 C}{\partial x^2} \]

Where:

\( D \) (diffusion coefficient) increases exponentially with temperature \( T \): \( D = D₀e^{Ea/RT} \).

Motorcycle battery casings (wall thickness: 0.6–1.2 mm) require 12–24 hours at 45–60°C to reach safe moisture activity (\( A_w ≤ 0.65 \)).

Critical Process Controls

Temperature zones: Multistage heating prevents casing deformation while maintaining optimal internal temperatures (50–55°C).

Gas flow optimization: Dry nitrogen purging at 2–5 L/min removes desorbed water molecules.

Vacuum drying: Pressures ≤10 mbar boost moisture removal rates by 70% in thick electrodes.

Advanced Drying Techniques for Motorcycle Batteries

MultiPhase Systems

1. Predrying phase: 80°C thermal treatment reduces surface moisture to ≤300 ppm.

2. Deep drying phase: 60°C vacuum chambers with molecular sieves achieve ≤50 ppm residual H₂O.

3. Storage conditioning: Humiditycontrolled environments (<1% RH) prevent moisture reabsorption.

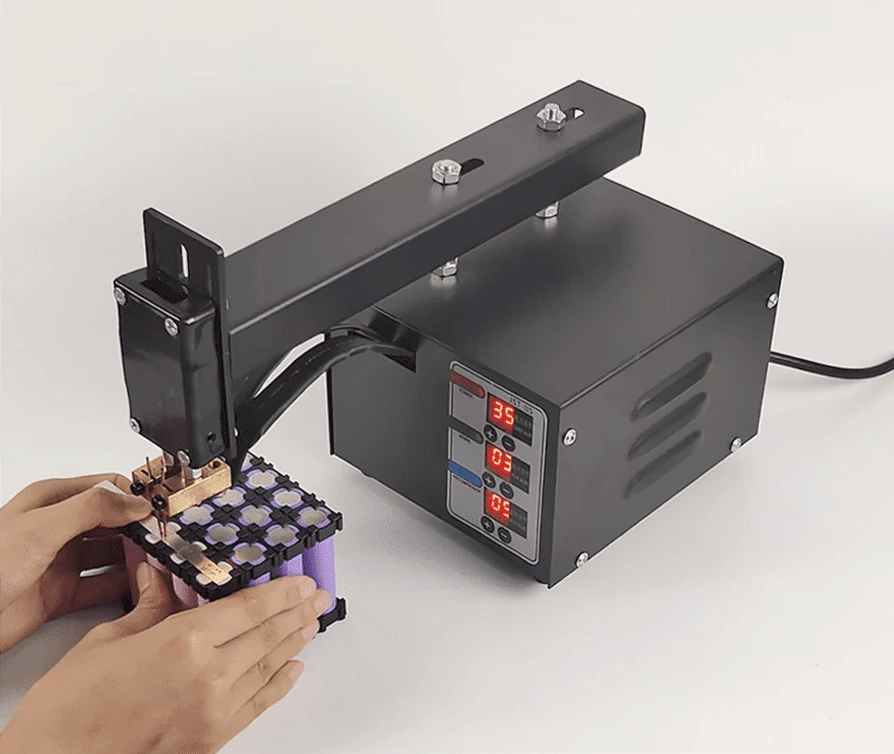

Quality Verification Methods

Karl Fischer titration: Measures H₂O content with ±5 ppm accuracy.

Thermogravimetric analysis (TGA): Identifies bound moisture via weight loss during heating.

Impedance testing: Detects early SEI layer damage caused by residual HF.

Why Precision Drying Ensures Battery Reliability

Extended lifespan: Cells dried to ≤200 ppm H₂O retain 90% capacity after 1,500 cycles at 45°C.

Safety compliance: IEC 626602 mandates ≤20 ppm HF in electrolytes postdrying.

Cost efficiency: Reduces moisturerelated defects by 40% through realtime humidity monitoring.

By aligning drying protocols with materialspecific desorption behaviors, manufacturers produce motorcycle batteries resistant to humidity, thermal stress, and mechanical shocks—delivering consistent power in demanding conditions.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!