Advanced Battery Cleaning Technologies

main content

Advanced battery cleaning technologies are revolutionizing manufacturing by eliminating contaminants with unprecedented speed and accuracy. This guide explores three groundbreaking methods—ultrasonic cleaning, low-temperature plasma treatment, and hydrocarbon solvent systems—detailing their technical advantages, process parameters, and quality improvements for high-performance battery assembly.

1. Ultrasonic Cleaning Technology: Speed and Precision

Modern ultrasonic systems deliver unmatched efficiency in electrode and casing cleaning while minimizing mechanical damage.

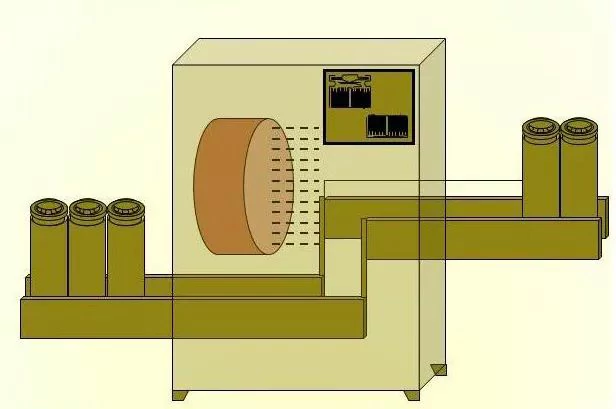

Automated Process Workflow

High-frequency agitation: 40 kHz ultrasonic waves (power density ≥1.5 W/cm²) paired with Musen cleaning agents (1:20 dilution at 60°C) achieve 4000 pieces/hour throughput.

Rinsing and drying: Deionized water (conductivity ≤1 μS/cm) removes ionic residues; centrifugal drying at 3000 rpm reduces moisture to ≤50 ppm.

Defect Prevention Strategies

Real-time monitoring: 5μm linear CCD cameras detect electrode misalignment, preventing edge abrasion (wavy edges ≤0.5 mm).

Energy optimization: Pulse-mode ultrasound cuts power consumption by 18% without compromising cleaning efficacy.

2. Low-Temperature Plasma Cleaning: Enhancing Surface Energy

Plasma treatments remove organic residues and activate surfaces for improved electrolyte adhesion, particularly in silicon-carbon anode systems.

Key Process Parameters

Gas mixture: Ar/O₂ (4:1 ratio) generates reactive species that oxidize hydrocarbons, boosting separator surface energy from 30 mN/m to 72 mN/m.

Performance gains: Electrolyte wetting time drops to 5 seconds; SEI layer uniformity improves, reducing anode swelling variation to ≤0.8 mm over 1000 cycles.

Application-Specific Benefits

Silicon anode compatibility: Plasma etching minimizes binder degradation during high-temperature cycling.

Cost efficiency: In-line plasma modules reduce solvent usage by 40% compared to traditional degreasing.

3. Hydrocarbon Solvent Innovations: Eco-Friendly Precision

Next-gen fluorinated hydrocarbon solvents combine superior cleaning power with environmental compliance.

Technical Breakthroughs

Solvent performance: F113-based formulations dissolve 98% of mineral oils while maintaining material compatibility with aluminum casings.

Emission control: Integrated vacuum distillation recovers ≥90% of solvents, slashing VOC emissions to ≤10 mg/m³—well below EPA thresholds.

Structural Enhancements

Porosity reduction: Aluminum shell porosity decreases from 2.5% to 0.8%, increasing burst pressure to 1.5 MPa.

Cycle stability: Cleaned electrodes show 22% lower dendrite formation rates in NMC 811 cells.

Synergizing Technologies for Maximum Impact

Integrated Production Lines

Modular design: Combine ultrasonic tanks, plasma chambers, and solvent recovery systems in a single footprint.

Smart sensors: IoT-enabled pH and conductivity meters adjust cleaning parameters dynamically.

Quality Assurance Protocols

Laser particle counters: Verify residual contaminant levels ≤0.3 ppm on cathode foils.

Tensile testing: Ensure weld strength consistency (±5% variance) after plasma-treated terminal cleaning.

Why Advanced Cleaning Defines Battery Manufacturing Success

Yield improvement: Automated ultrasonic systems reduce scrap rates by 30–35%.

Sustainability: Closed-loop solvent recycling meets EU REACH and RoHS directives.

Performance metrics: Plasma-treated cells achieve 99.2% initial Coulombic efficiency in 4.4V LiCoO₂ systems.

By adopting these advanced battery cleaning technologies, manufacturers achieve tighter tolerances, faster production speeds, and greener operations—critical advantages in the competitive EV and energy storage markets.

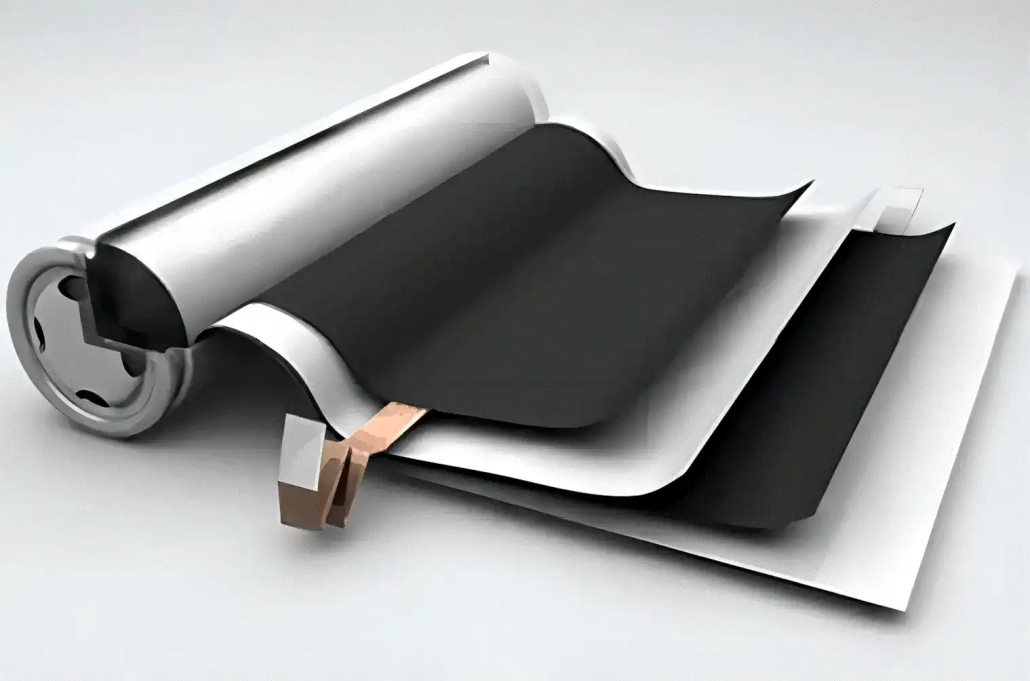

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!