Temperature Sensing Network in BMS

main content

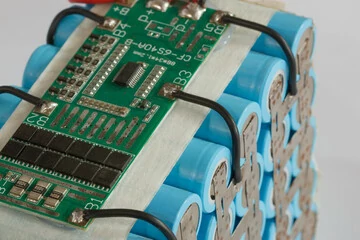

The temperature sensing network in a motorcycle lithium battery BMS is a critical subsystem designed to monitor thermal conditions, prevent failures, and optimize performance. By integrating sensors, signal processing units, and control algorithms, this network ensures safe operation across extreme environments while extending battery lifespan. Below, we break down its core components, functional roles, and design considerations.

Core Components of the Temperature Sensing Network

1.Sensor Types and Placement

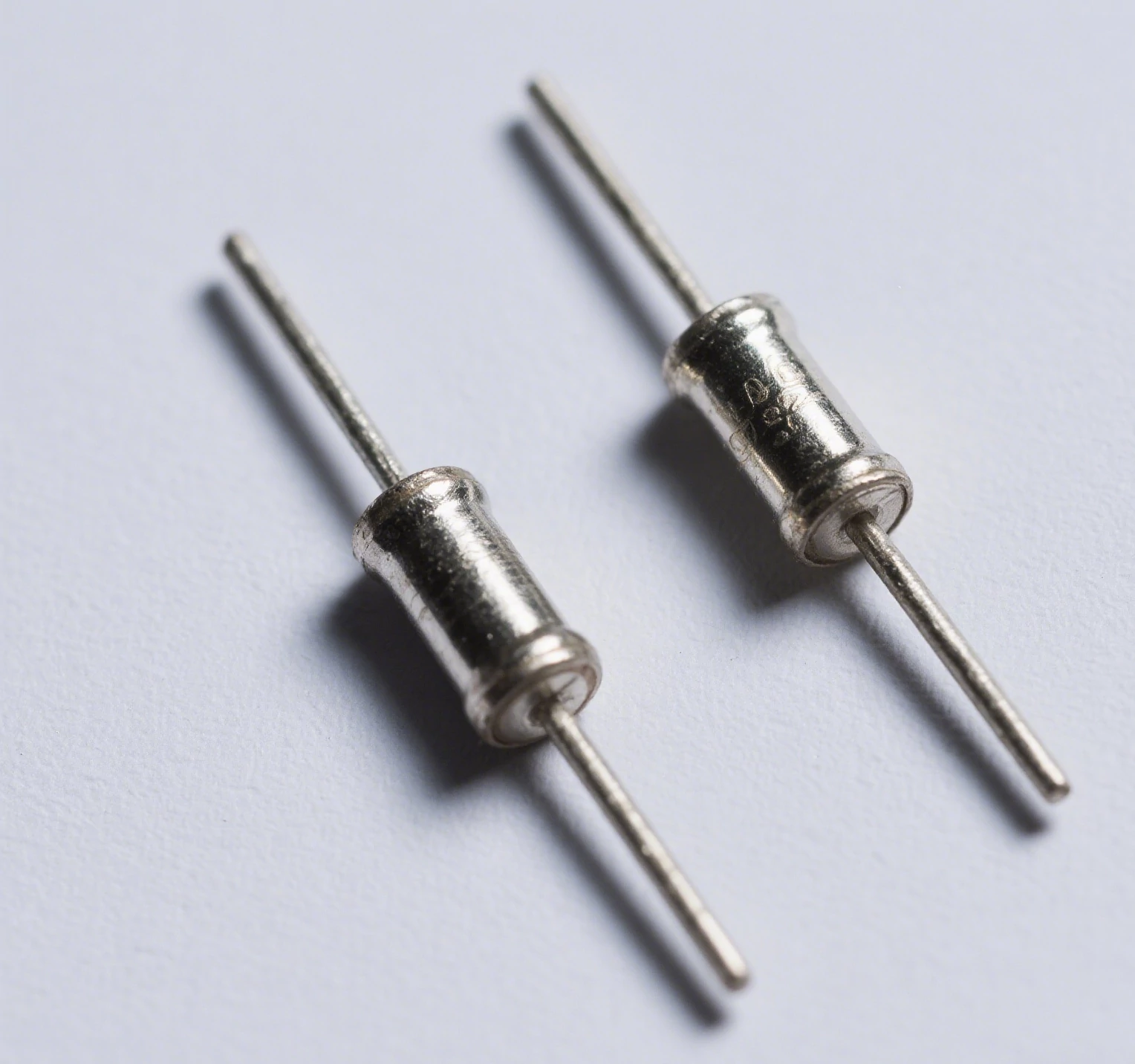

Thermistors and Thermocouples: These are widely used due to their cost-effectiveness and reliability. Thermistors (e.g., NTC types) provide high sensitivity to temperature changes, while thermocouples handle broader temperature ranges (-40°C to 150°C) common in motorcycle applications.

Digital Sensors (e.g., DS18B20): Offer precise measurements (±0.5°C accuracy) and simplify data integration via digital outputs like I2C or SPI. They are often embedded near cell terminals or between tightly packed modules to capture localized heat buildup.

Infrared Non-Contact Sensors: Used in advanced BMS designs to monitor cell surfaces without physical contact, reducing wiring complexity and improving durability in high-vibration setups.

Sensors are strategically placed at hotspots such as cell terminals, module centers, and near balancing circuits to detect thermal anomalies early.

2.Signal Conditioning and Data Processing

Amplifiers and ADCs: Raw sensor signals are filtered and amplified using silicon-based operational amplifiers before analog-to-digital conversion (e.g., 16-24 bit resolution). This minimizes noise interference from engine vibrations or electromagnetic fields.

Microcontroller Integration: Processed data is analyzed by the BMS microcontroller (e.g., STM32 or Texas Instruments C2000) to trigger actions like current throttling or cooling activation.

3.Redundancy and Fail-Safe Design

Multiple sensors per module and cross-verification algorithms prevent single-point failures. For example, if one sensor reports abnormal temperatures, the system cross-checks adjacent sensors to avoid false alarms.

Functional Roles of the Temperature Network

1.Real-Time Thermal Monitoring

Continuous tracking of cell and module temperatures ensures operation within safe limits (typically -20°C to 60°C). Sudden spikes during high-current events, such as engine ignition, are flagged instantly to prevent thermal runaway.

2.Active Thermal Management Cooling Activation: If temperatures exceed thresholds, the BMS triggers cooling mechanisms (e.g., fans or liquid cooling loops) or reduces charging/discharging rates. Low-Temperature Protection: Below 0°C, lithium plating risks during charging are mitigated by preheating systems or current limitation.

3.Cell Balancing and Efficiency Optimization

Temperature data aids in identifying cells with higher internal resistance, which generate more heat. The BMS redistributes loads or initiates passive/active balancing to equalize temperatures and prolong pack life.

4.Data Logging and Predictive Maintenance

Historical temperature trends help predict aging patterns or faulty cells. For instance, gradual temperature increases in a specific module may indicate impending cell degradation, prompting timely replacements.

Why a Robust Temperature Network Matters

Safety Assurance: Prevents catastrophic failures like thermal runaway, which can lead to fires or explosions in high-energy lithium batteries.

Performance Consistency: Maintains optimal operating temperatures to avoid voltage sag or capacity loss during extreme weather.

Regulatory Compliance: Meets international standards (e.g., UN38.3, IEC 62133) requiring rigorous thermal monitoring for lithium batteries.

Conclusion

The temperature sensing network in motorcycle lithium battery BMS combines precision sensing, intelligent control, and redundancy to ensure reliability in harsh conditions. From thermistor-based detection to predictive analytics, each component plays a vital role in safeguarding riders and enhancing battery efficiency. For manufacturers and users alike, investing in advanced thermal management systems translates to longer battery life, reduced maintenance costs, and unparalleled safety.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!