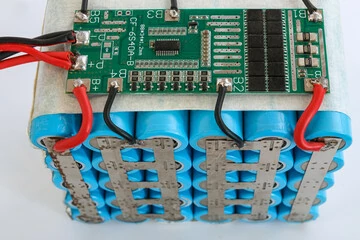

Safety Isolation Materials in Motorcycle Lithium Battery BMS

main content

Safety isolation materials form the foundation of robust motorcycle lithium battery BMS systems. These specialized substances prevent electrical hazards, manage thermal stress, and ensure long-term reliability under harsh operating conditions. Combining cutting-edge engineering with heat-resistant and dielectric properties, they enable precise energy control while safeguarding riders and battery integrity. Below, we analyze their core material categories, functional advantages, and emerging innovations.

Core Material Categories

1.Optocoupler/Optoisolator Components

Optocouplers rely on gallium arsenide (GaAs) or silicon (Si) photodiodes paired with infrared LEDs. Light signals transmit data across isolation barriers, eliminating direct electrical contact. Advanced designs integrate epoxy resins with high dielectric strength (>5 kV/mm) to withstand voltage spikes common in motorcycle vibration environments.

2.Isolated DC-DC Converter Substrates

Polyimide films and ceramic-based substrates dominate high-voltage DC-DC converters. These materials provide thermal stability (up to 150°C) and low parasitic capacitance, minimizing energy loss. For example, aluminum oxide (Al₂O₃) ceramics in 4–5 kV isolation layers ensure leakage currents remain below 1 µA even in multi-cell configurations.

3.Galvanic Isolation Barriers

Mica-reinforced composites and epoxy-laminated sheets create robust galvanic isolation between battery packs and chassis. Materials with insulation resistance exceeding 35 kΩ at 350V systems prevent ground faults. Innovations like graphene-enhanced polymers further reduce capacitive coupling while improving heat dissipation.

4.Thermal Management Layers

Synthetic diamond coatings and silicon carbide (SiC) substrates dissipate heat from high-current components. These materials achieve thermal conductivity rates of 1,500–2,000 W/m·K, preventing thermal runaway in compact BMS designs. Phase-change materials (PCMs) embedded in isolation layers absorb excess heat during rapid charging cycles.

Functional Advantages of Advanced Materials

Electrical Safety: Ceramic-filled silicones and fluoropolymer coatings resist arcing, maintaining isolation integrity at voltages up to 1,500V.

Vibration Resistance: Fiber-reinforced epoxy matrices endure 10–50G mechanical shocks, critical for off-road motorcycles.

Chemical Stability: Hydrocarbon-resistant polyurethanes protect against electrolyte leaks and environmental moisture.

Compliance: Automotive-grade materials meet AEC-Q100 and ISO 16750-2 standards for temperature cycling (-40°C to 125°C) and humidity resistance.

Emerging Innovations

Graphene-Based Barriers: Single-atom-thick graphene oxide films reduce Hg vapor permeability by 90% while offering ultra-low capacitance for 800V+ systems.

Rare-Earth-Free Magnetics: Iron-nitrogen (FeN) composites replace traditional ferrites, cutting costs and improving high-frequency performance.

Self-Healing Polymers: Microcapsule-embedded resins automatically repair insulation cracks caused by mechanical stress.

Conclusion

Safety isolation materials are indispensable for next-generation motorcycle lithium battery BMS systems. From vibration-resistant ceramics to graphene-enhanced barriers, their role in balancing electrical safety, thermal management, and mechanical durability continues to evolve. As material science advances, these components will drive lighter, smarter, and more sustainable energy solutions for global riders.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!