Motorcycle Starter Battery Winding Process: Advanced Techniques for Vibration Resistance

main content

The motorcycle Starter battery winding process demands unique engineering solutions to withstand extreme mechanical stresses. Unlike conventional batteries, motorcycle batteries endure frequent vibrations (up to 1020g acceleration) and sudden shocks during ignition. This article explores three critical innovations—high-precision tab alignment, thermal bonding, and gradient tension control—that ensure structural stability and longevity in harsh riding conditions.

Core Innovations Enhancing Vibration Resistance

1. High-Precision Tab Alignment

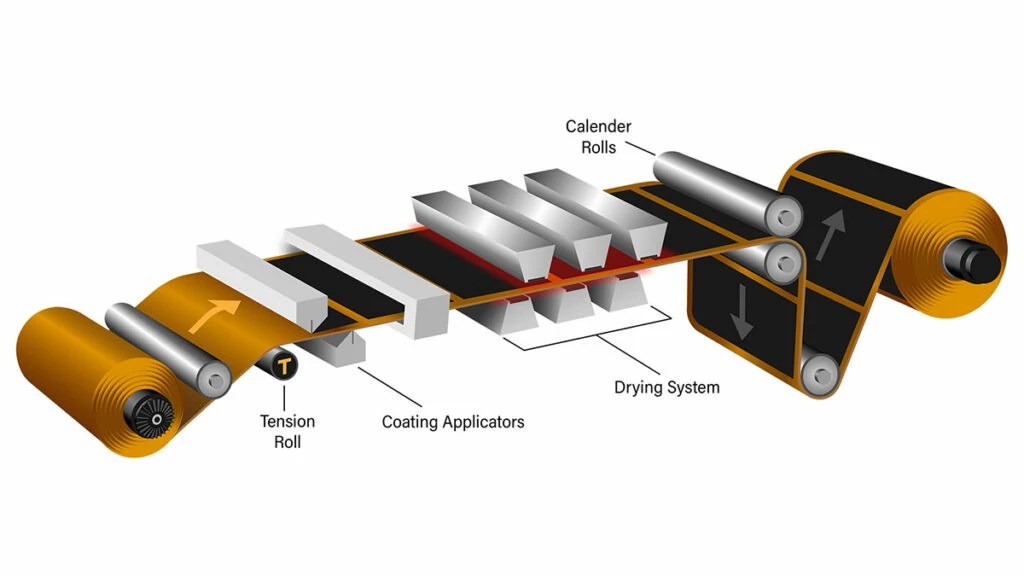

Accurate tab positioning is vital for minimizing internal resistance and weld defects. Advanced techniques include:

Laser die-cutting: Achieves burr-free edges (≤5μm) on tabs, reducing short-circuit risks during high-frequency vibrations.

Closed-loop alignment correction: Maintains tab spacing tolerance within ±0.3mm using real-time vision systems. This precision lowers virtual welding risks by 40%, ensuring reliable electrical connectivity.

Multi-layer stacking control: Aligns anode/cathode layers with <0.1° angular deviation for uniform current distribution.

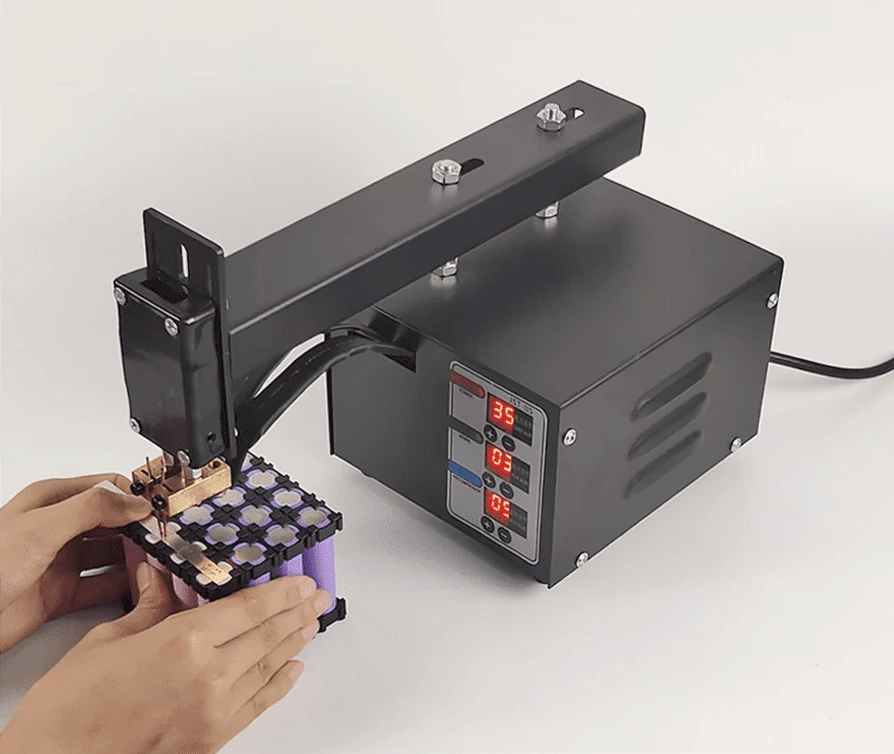

2. Thermal Bonding Technology

Heat-induced layer slippage is a major failure mode in vibrating environments. Solutions include:

Patterned anode surfaces: Embossed textures (applied at 0.3MPa pressure) increase interlayer friction by 55%, reducing cyclic expansion by 20% .

Low-melt polymer coatings: Applied to separator edges, these coatings activate at 80°C, forming localized bonds that lock layers during thermal shocks.

Post-winding compression: A 5-ton press applies uniform pressure to enhance interfacial adhesion before cell aging.

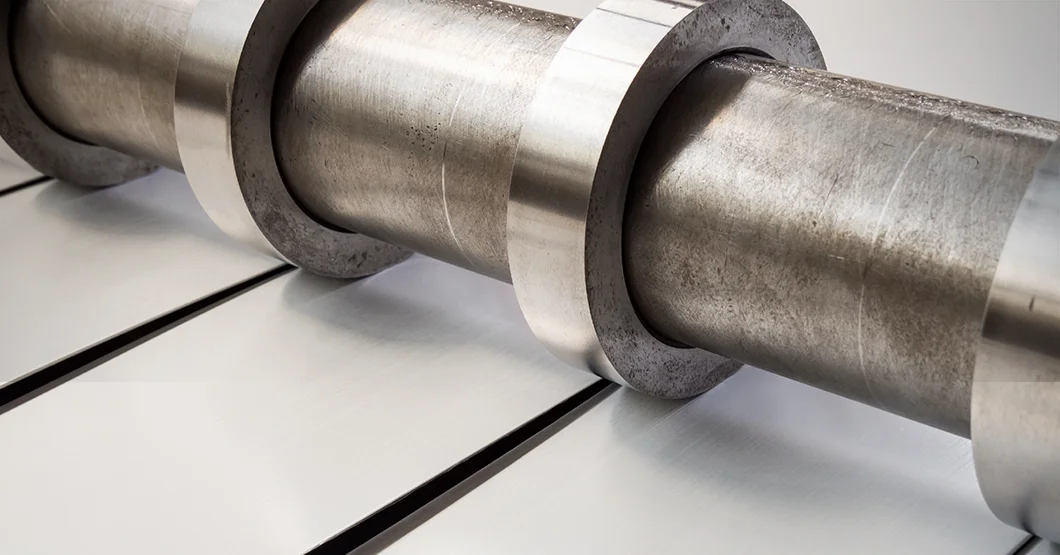

3. Gradient Tension Control

Tension mismatches during winding cause internal stress buildup. Key strategies:

Tapered tension profiles: Starting at 180gf, tension decreases by 25gf per winding cycle to balance radial and axial forces.

Dynamic radius compensation: Adjusts winding speed based on real-time radius calculations using Archimedean spiral models, preventing outer-layer slack.

Elastic modulus matching: Optimizes separator/electrode stiffness ratios (1:3) to absorb vibration energy without delamination.

Performance Benefits

Shock absorption: Reduces layer displacement by 90% under 1020g vibration loads.

Cycle life extension: Achieves 1,500+ deep cycles with <15% capacity loss.

Thermal stability: Maintains structural integrity from -30°C to 75°C.

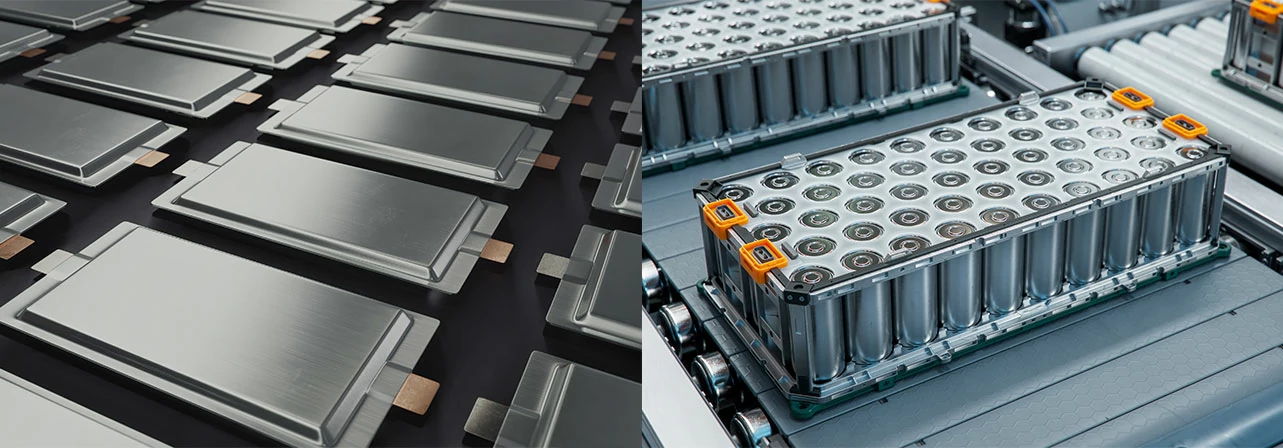

Applications in Modern Motorcycle Batteries

These techniques are critical for:

High-cranking batteries: Delivers 800A pulse currents for electric start systems.

Lithium-iron phosphate (LFP) cells: Supports ultra-thin electrodes (≤80μm) with 98% stacking density.

Modular packs: Enforces uniform tension across parallel-connected cells for balanced aging.

Conclusion

Mastering the motorcycle Starter battery winding process requires harmonizing precision mechanics, material science, and dynamic control algorithms. By integrating laser cutting, thermal bonding, and adaptive tension systems, manufacturers can produce batteries that withstand extreme vibrations while delivering consistent power output—a necessity for modern electric motorcycles and high-performance combustion engines.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!