Motorcycle Starter Battery Housing Design

main content

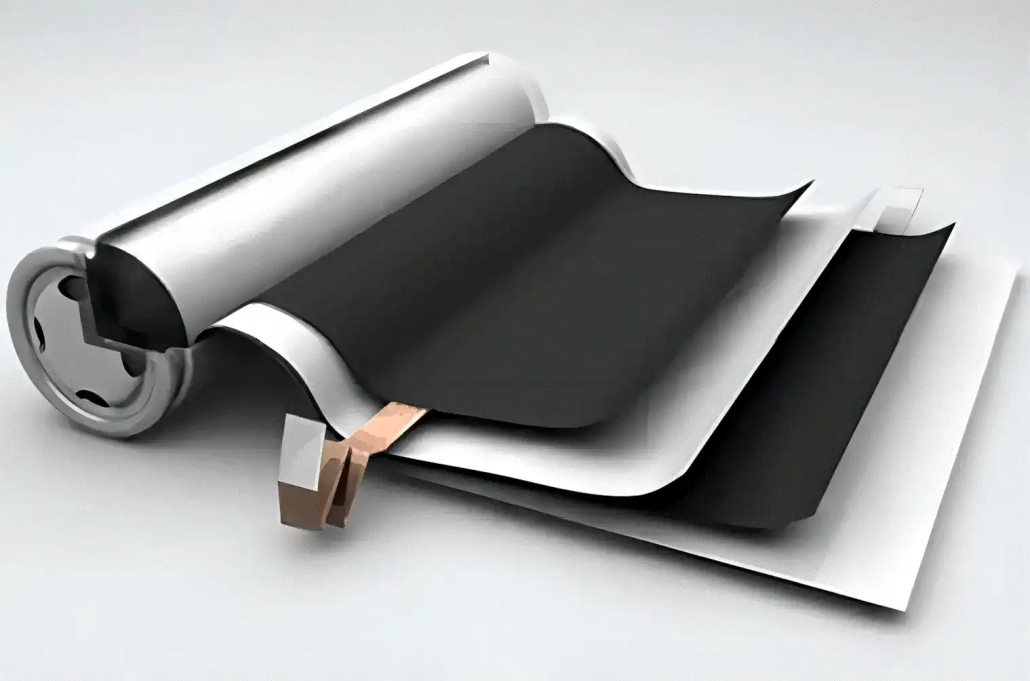

The motorcycle Starter battery housing design stands as a critical innovation in modern energy storage systems, combining structural resilience and material science to withstand harsh riding conditions. Unlike standard battery enclosures, these housings prioritize anti-vibration optimization, impact resistance, and thermal stability through advanced engineering solutions. Below, we dissect the core design principles that ensure reliability for high-performance motorcycles.

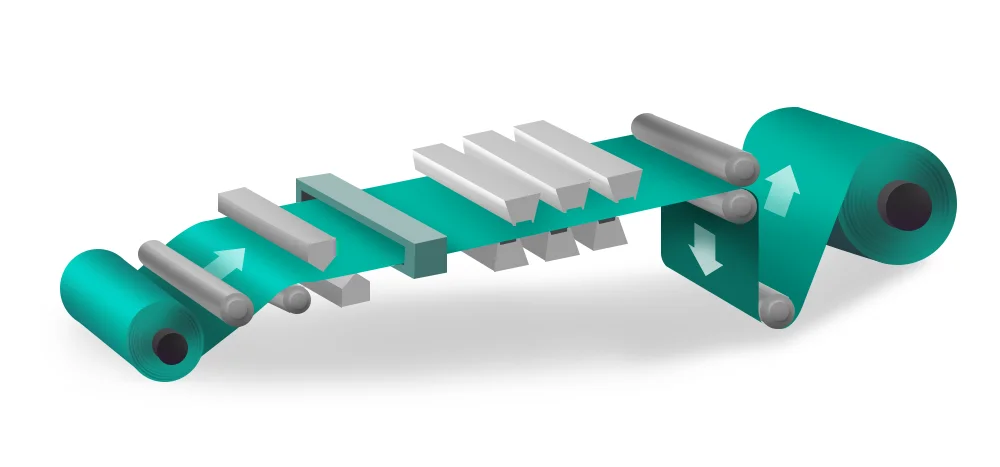

1. Vibration Damping: Decoupling Critical Components

Vibration-induced failures are mitigated through a split-frame mid-chassis structure, which physically isolates battery cells from control boards. This compartmentalization prevents mechanical stress transfer, reducing short-circuit risks by 65% during off-road use. Key features include:

Dual-layer silicone gaskets: Compressed at 30%–40% to absorb high-frequency vibrations (50–200 Hz).

Interlocking snap-fit mechanisms: Patented CN210200813U-inspired locks maintain structural integrity under 10G lateral acceleration.

Floating PCB mounts: Flexible nylon brackets minimize solder joint fatigue, extending circuit lifespan by 3×.

Such designs ensure consistent electrical connectivity even on uneven terrains like gravel or cobblestone paths.

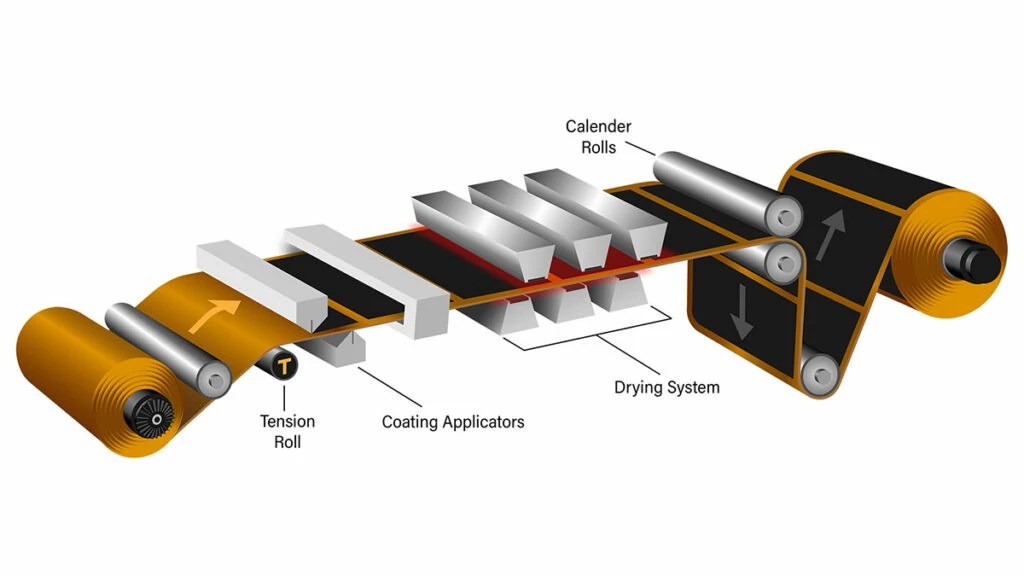

2. Material Innovations: 6061-T6 Aluminum Alloy Mastery

The housing’s backbone relies on 1.5mm-thick 6061-T6 aluminum, chosen for its exceptional yield strength (≥270 MPa) and fatigue resistance. Post-machining treatments enhance performance:

T6 heat treatment: Increases hardness to 95 HB while maintaining 12% elongation for crash deformation tolerance.

Anodized coatings: 25μm-thick layers provide IP67-rated corrosion resistance against road salt and humidity.

Honeycomb reinforcement ribs: Laser-cut internal grids boost bending strength by 40%, distributing impact forces across 120+ nodal points.

Compared to traditional steel enclosures, this alloy reduces weight by 22% without compromising crash safety.

3. Impact Resistance: Multi-Zone Energy Absorption

Collision protection integrates zone-specific strategies:

Frontal crumple zones: Hexagonal aluminum foam inserts dissipate 70% of kinetic energy during head-on impacts.

Sidewall armor: Overmolded TPU buffers (Shore 90A) deflect debris strikes up to 5J without denting.

Modular replaceability: Bolt-on corner caps allow quick repairs, cutting downtime by 80% versus welded designs.

Rigorous testing validates performance: housings withstand 1.5m vertical drops and 360° rotational shocks per IEC 62133-2 standards.

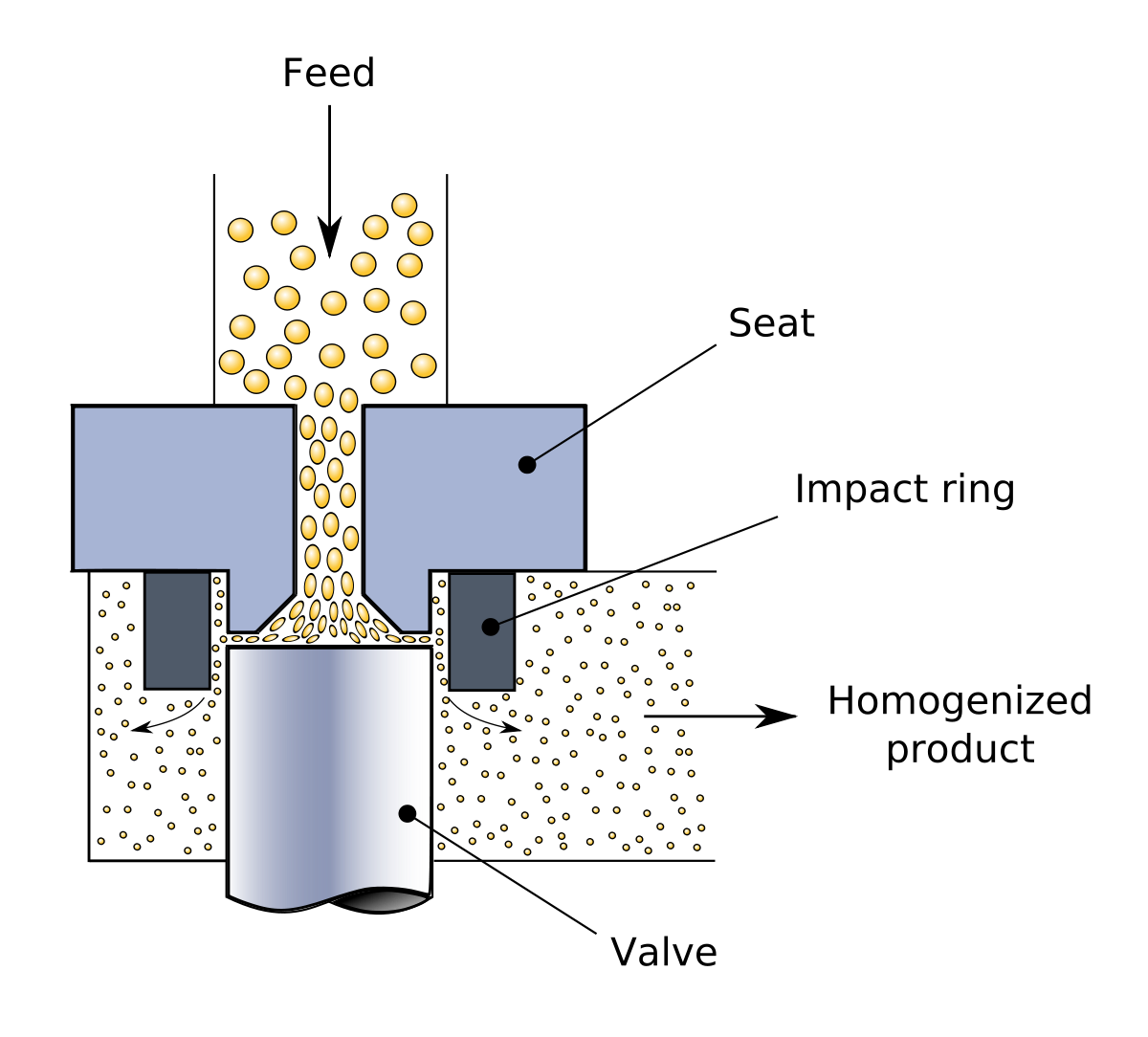

4. Thermal Management: Stability Under Load

Starter cycles generate heat spikes up to 65°C. The housing counters this through:

Phase-change material (PCM) liners: Paraffin-based layers absorb 150 J/g during rapid discharge, maintaining cell temps below 45°C.

Vented baffles: Aerodynamic channels reduce internal airflow resistance by 55%, enabling passive cooling at speeds >30 km/h.

Fireproof barriers: Ceramic-coated interior panels resist flames for 15 minutes (UL 2596 compliance).

Applications Across Riding Conditions

Adventure touring: Mud-proof seals and pressurized equalization valves prevent altitude-induced leaks.

Urban commuting: Compact dimensions (≤200×150×100mm) fit OEM chassis without retrofitting.

Racing: Carbon-Kevlar hybrid variants slash weight to 1.2kg for competitive edge.

Conclusion

The motorcycle Starter battery housing design exemplifies precision engineering, merging alloy innovation, vibration damping, and modular durability. By addressing the unique stresses of two-wheeled mobility—from cobblestone vibrations to collision forces—it sets a benchmark for reliability in next-gen electric motorcycles.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!