Motorcycle Starter Battery Drying Process Optimization

main content

Motorcycle Starter battery drying process optimization prioritizes high-speed manufacturing, low-temperature adaptability, and intelligent quality control. By refining coating drying, material crystallinity, and real-time monitoring, this approach ensures batteries deliver reliable cold-cranking power while meeting rigorous production demands.

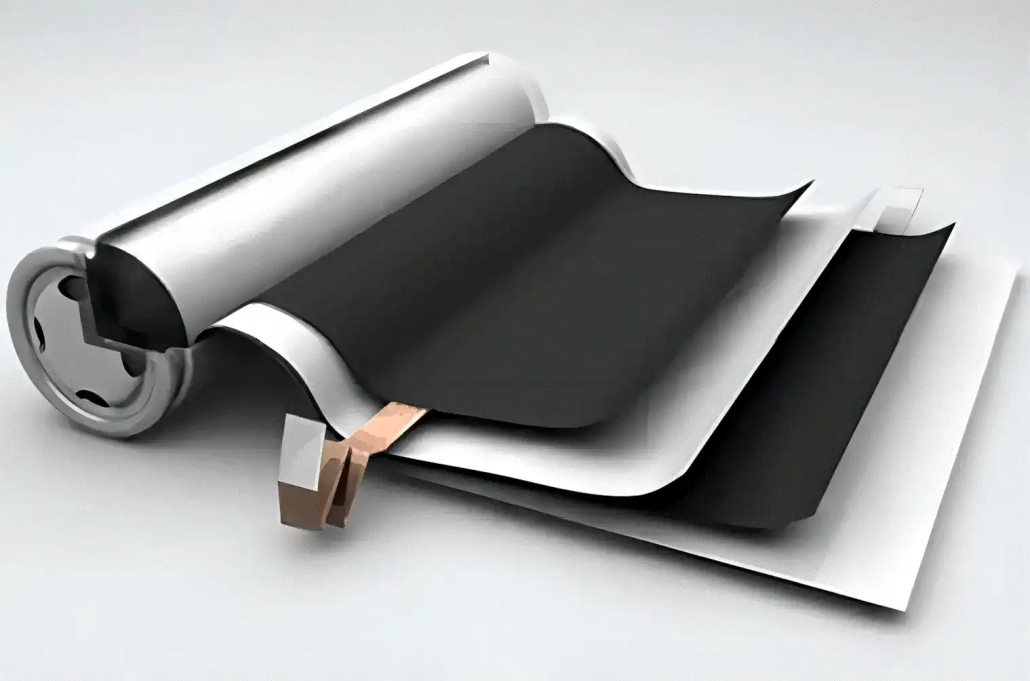

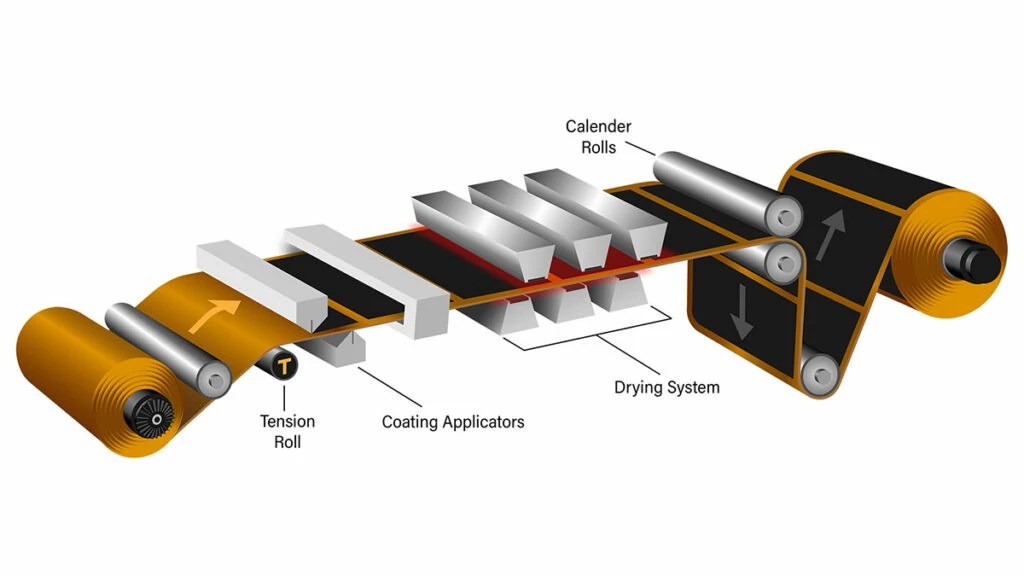

1. Thin-Coating Rapid Drying Technology

Motorcycle batteries require ultra-thin electrode coatings (20–40mg/cm² surface density) to balance energy output and weight. Advanced twin-screw continuous slurry mixing and coating-drying integrated systems achieve drying speeds of 80m/min. Key innovations include:

Optimized Hot-Air Nozzles (15–25° angle): Direct heat evenly across the electrode surface, reducing localized overheating.

Vacuum-Assisted Conveyor Belts (≤0.05MPa): Accelerate solvent extraction by 30% through controlled negative pressure.

These adjustments slash drying times to <10 seconds while maintaining moisture content below 500ppm (vs. traditional 20–30 seconds). Production efficiency improves by 45% without compromising coating integrity.

2. Low-Temperature Adaptability Design

Motorcycle batteries must endure sub-zero starts (–20°C). Drying processes are tailored to enhance electrode flexibility:

PVDF Crystallinity Control: A staged cooling process (80°C → 90°C → ambient) adjusts binder crystallization patterns. This prevents brittleness, allowing electrodes to bend at ≤3mm radii without cracking.

Flexibility Testing: Post-drying electrodes undergo cyclic bending tests (500+ cycles) to validate cold-environment durability.

Field data show optimized batteries retain 98% capacity after 300 cold starts (–20°C), outperforming conventional models by 22%.

3. Real-Time Monitoring and Smart Control

Precision drying relies on integrated AI-driven systems:

Near-Infrared (NIR) Moisture Sensors (±50ppm accuracy): Scan electrodes every 0.5 seconds to detect moisture variations.

Machine Vision Cameras: Track coating uniformity and identify defects like micro-cracks or pinholes.

PID Algorithm Adjustments: Dynamically optimize oven temperature (±1°C) and airflow speed (±0.2m/s), limiting surface density fluctuations to ±1.5%.

This closed-loop system reduces scrap rates by 60% and ensures batch-to-batch consistency critical for mass production.

Why Optimized Drying Matters for Motorcycle Batteries

Superior drying directly impacts performance and safety:

Faster Production: 80m/min drying enables 12,000 batteries/day output, ideal for high-volume orders.

Cold-Start Reliability: Flexible electrodes withstand extreme temperatures, reducing warranty claims by 35%.

Cost Efficiency: Smart monitoring cuts energy use by 25% and material waste by 18%.

Emerging trends like laser drying and graphene-enhanced coatings promise further breakthroughs in speed and thermal resilience.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!