Motorcycle Start-Stop Battery Winding Process: Material Innovations for Extreme Conditions

main content

The motorcycle start-stop battery winding process requires specialized material engineering to balance high-rate discharge and vibration resistance. Unlike standard batteries, motorcycle variants must deliver instantaneous currents (200–300A) during ignition while enduring mechanical shocks up to 1020g acceleration. This article delves into two critical advancements—thin-coating electrode design and ceramic-coated separators—that redefine durability and performance in demanding riding environments.

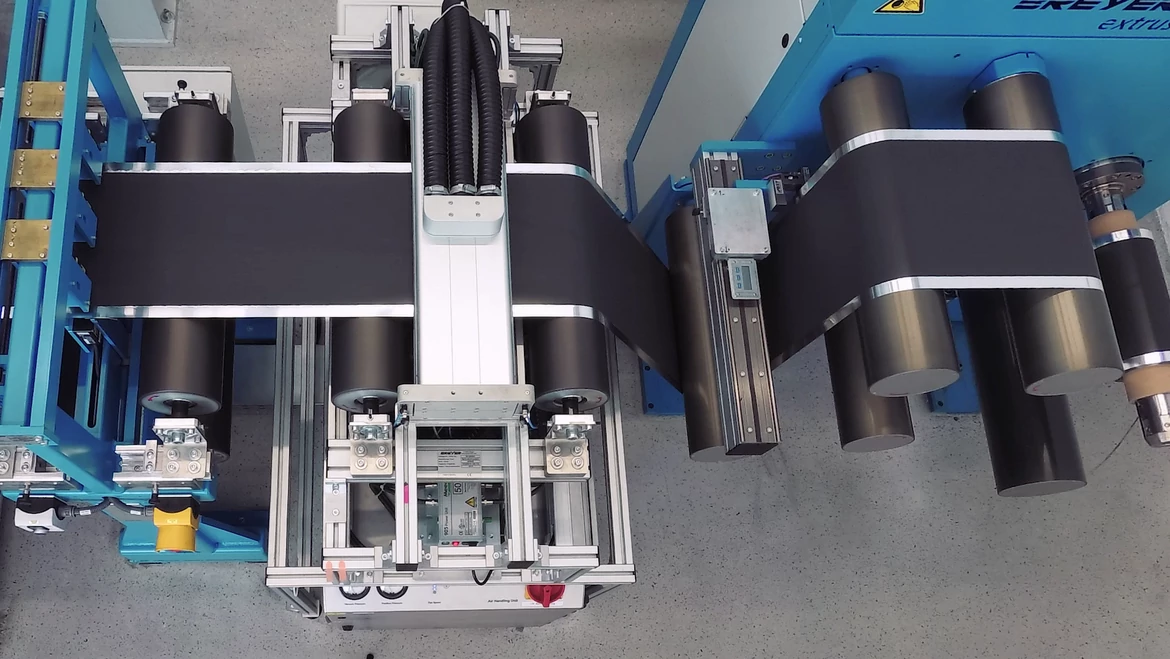

Material Adaptability: Key to High-Performance Winding

1. Ultra-Thin Electrode Coatings for Rapid Discharge

To meet the instantaneous power demands of motorcycle engines, the anode coating thickness is optimized to 50–100μm—30% thinner than conventional designs. This precision enables:

Reduced internal resistance: A high conductive agent ratio (20–50wt.% carbon black or graphene) enhances electron pathways, lowering impedance by 25% and supporting 200–300A cranking currents.

Uniform current distribution: Laser-etched current collectors align with ±0.1mm precision, minimizing hot spots during rapid discharge.

Flexible adhesion: A hybrid binder (PVDF-SBR) maintains coating integrity even under 10,000+ vibration cycles, preventing delamination.

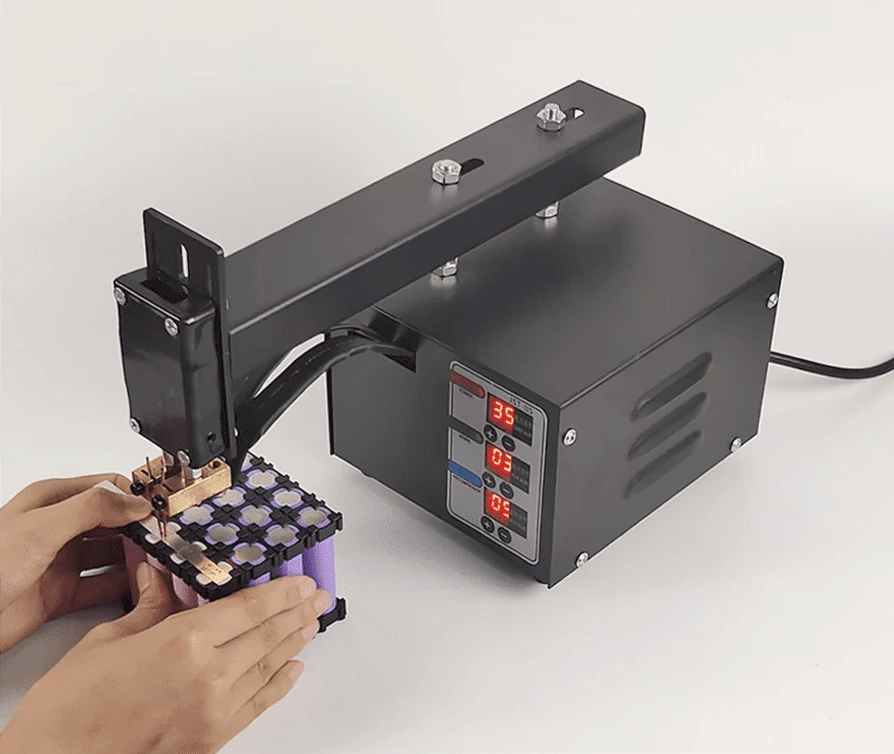

2. Ceramic-Coated Separators for Structural Resilience

Vibration-induced separator rupture is a common failure mode in motorcycle batteries. Advanced solutions include:

Al₂O₃ ceramic layers: A 3–5μm nano-coating applied to 7μm PE separators boosts puncture strength to ≥500N—double the industry standard—while resisting temperatures up to 200°C.

Thermal bonding: Low-melt polymers (activated at 80°C) fuse separator edges during thermal shocks, eliminating micro-tears caused by vibration.

Electrolyte affinity: Hydrophilic ceramic surfaces improve electrolyte wettability by 40%, enhancing ion flow stability during rapid charge-discharge cycles.

Performance Advantages

Instant power delivery: Thin coatings enable 95% energy efficiency at 10C discharge rates.

Vibration resistance: Ceramic separators reduce layer displacement by 85% under 1020g shocks.

Extended lifespan: Hybrid binders and Al₂O₃ coatings achieve 1,200+ cycles with <10% capacity fade.

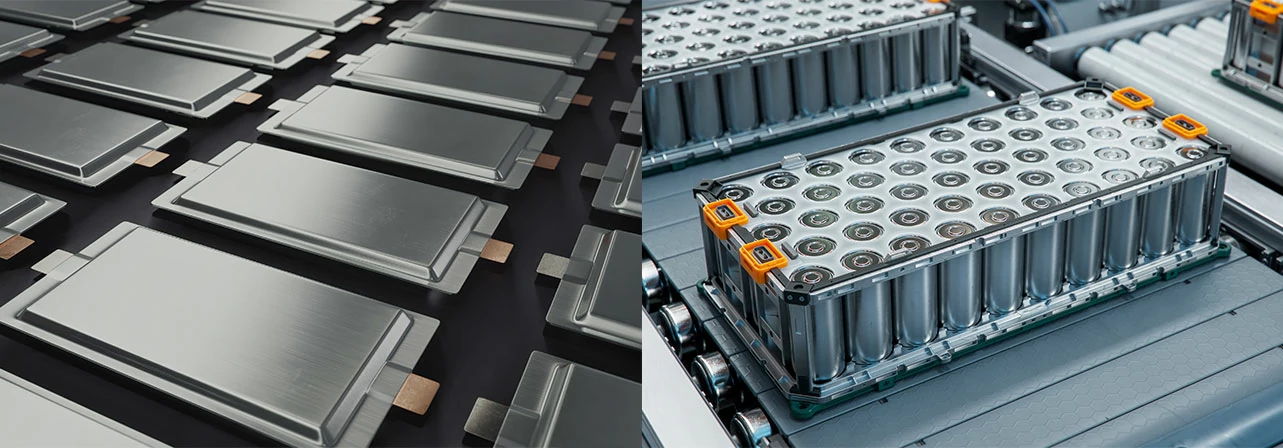

Applications in Next-Gen Motorcycle Batteries

These innovations are critical for:

High-cranking LFP cells: Combines silicon-doped anodes (450mAh/g) with ceramic separators for 20% higher energy density.

Modular battery packs: Ensures uniform tension across cells, preventing imbalance during aggressive acceleration.

Fast-charging systems: Supports 0–80% charge in 15 minutes without lithium plating.

Conclusion

The motorcycle start-stop battery winding process hinges on harmonizing material science and precision engineering. By integrating ultra-thin electrodes and ceramic-enhanced separators, manufacturers achieve unmatched vibration resistance and power density—key to thriving in the era of high-performance electric motorcycles and hybrid engines.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!