Motorcycle Lithium Battery BMS Enclosure Materials

main content

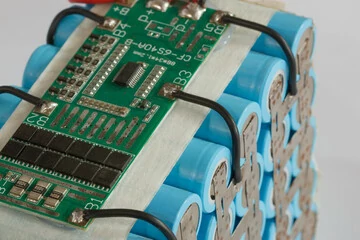

Motorcycle lithium battery BMS enclosure materials are the unsung heroes of modern power systems, combining rugged protection with precision thermal management. Designed to withstand vibration, extreme temperatures, and environmental hazards, these structural components ensure the battery management system (BMS) operates flawlessly under demanding riding conditions. From aerospace-grade alloys to impact-resistant polymers, material innovation drives reliability while balancing weight and cost. Below, we explore critical material categories, functional priorities, and cutting-edge advancements shaping this field.

Core Material Innovations

1.High-Strength Aluminum Alloys

Lightweight yet durable, aluminum alloys like 6061-T6 dominate enclosure designs for their optimal strength-to-weight ratio. Advanced anodizing processes enhance corrosion resistance, critical for off-road motorcycles exposed to mud and road salts. Extruded aluminum profiles integrate cooling fins to passively dissipate heat from high-current BMS circuits, maintaining temperatures below 60°C even during rapid charging cycles.

2.Fiber-Reinforced Engineering Polymers

Glass-filled nylon (PA6-GF30) and polycarbonate composites provide exceptional impact resistance while reducing enclosure weight by up to 40% compared to metals. These polymers excel in vibration dampening, absorbing shocks from rough terrains without compromising structural integrity. UV-stabilized variants prevent yellowing and brittleness under prolonged sunlight exposure, ensuring long-term aesthetics.

3.Hybrid Metal-Composite Designs

Combining stainless steel frames with carbon fiber panels achieves unmatched rigidity for high-performance applications. The steel skeleton absorbs mechanical stress during crashes, while carbon fiber minimizes weight and electromagnetic interference (EMI) – a critical factor for BMS signal accuracy. Laser-welded seams and silicone gaskets achieve IP67 waterproofing, preventing moisture ingress in monsoon conditions.

Functional Priorities in Enclosure Engineering

Thermal Regulation: Phase-change materials (PCMs) embedded in enclosure walls absorb excess heat during fast charging, delaying thermal runaway risks by 15–20 minutes. Liquid-cooled variants circulate dielectric fluids around BMS boards, stabilizing temperatures within ±2°C of optimal ranges.

Vibration Resistance: Torsional rigidity is paramount – enclosures must endure 10–50G shocks without cracking. Finite element analysis (FEA)-optimized ribbing patterns distribute stress evenly, while elastomer-mounted PCB trays isolate sensitive components from high-frequency vibrations.

Fire Safety: UL94 V-0 rated polymers and intumescent coatings expand when exposed to flames, creating a char layer that delays fire spread. Ceramic firewalls between cells and BMS circuitry provide 30+ minutes of flame containment.

EMI Shielding: Conductive nickel coatings or embedded metal meshes reduce electromagnetic noise by 60–80 dB, preventing false BMS sensor readings caused by ignition systems or aftermarket electronics.

Emerging Material Technologies

Graphene-Enhanced Composites: Adding 2% graphene nanoparticles to polymer matrices improves tensile strength by 200% while enabling embedded strain sensors for real-time structural health monitoring.

Self-Healing Elastomers: Microcapsules filled with reactive monomers automatically seal hairline cracks caused by impacts, restoring waterproofing and extending enclosure lifespan by 3–5 years.

3D-Printed Lattice Structures: Topology-optimized titanium lattices reduce weight by 70% compared to solid metal housings while maintaining crash resistance. Selective laser melting (SLM) allows customized airflow channels for targeted BMS cooling.

Conclusion

The evolution of motorcycle lithium battery BMS enclosure materials reflects a relentless pursuit of safety and performance. From vibration-damping polymers to smart self-repairing alloys, these materials form the first line of defense against mechanical and thermal stresses. As electric motorcycles push power density limits, future enclosures will likely integrate embedded cooling systems and AI-driven structural health analytics – transforming passive shells into active safety guardians.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!