Motorcycle Lithium Battery BMS Connectors

main content

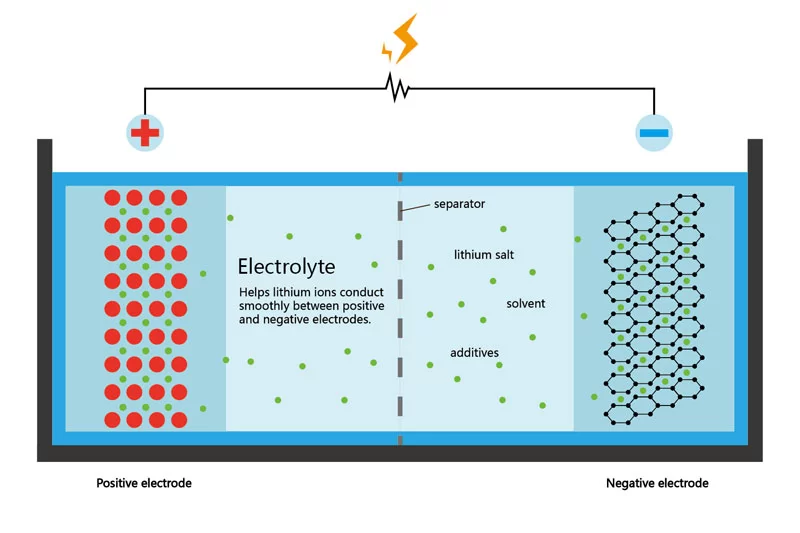

Motorcycle lithium battery BMS connectors serve as critical lifelines between battery cells and control systems, ensuring seamless energy transfer even under extreme riding conditions. Designed to withstand relentless vibrations, temperature fluctuations, and electromagnetic interference, these connectors directly impact safety, efficiency, and longevity. From gold-plated terminals to hybrid polymer housings, material innovation and structural optimization define modern BMS connector design. Below, we dissect key connector types, functional priorities, and emerging advancements shaping this essential component.

Core Technologies in BMS Connector Design

1.Vibration-Resistant Metal Alloys

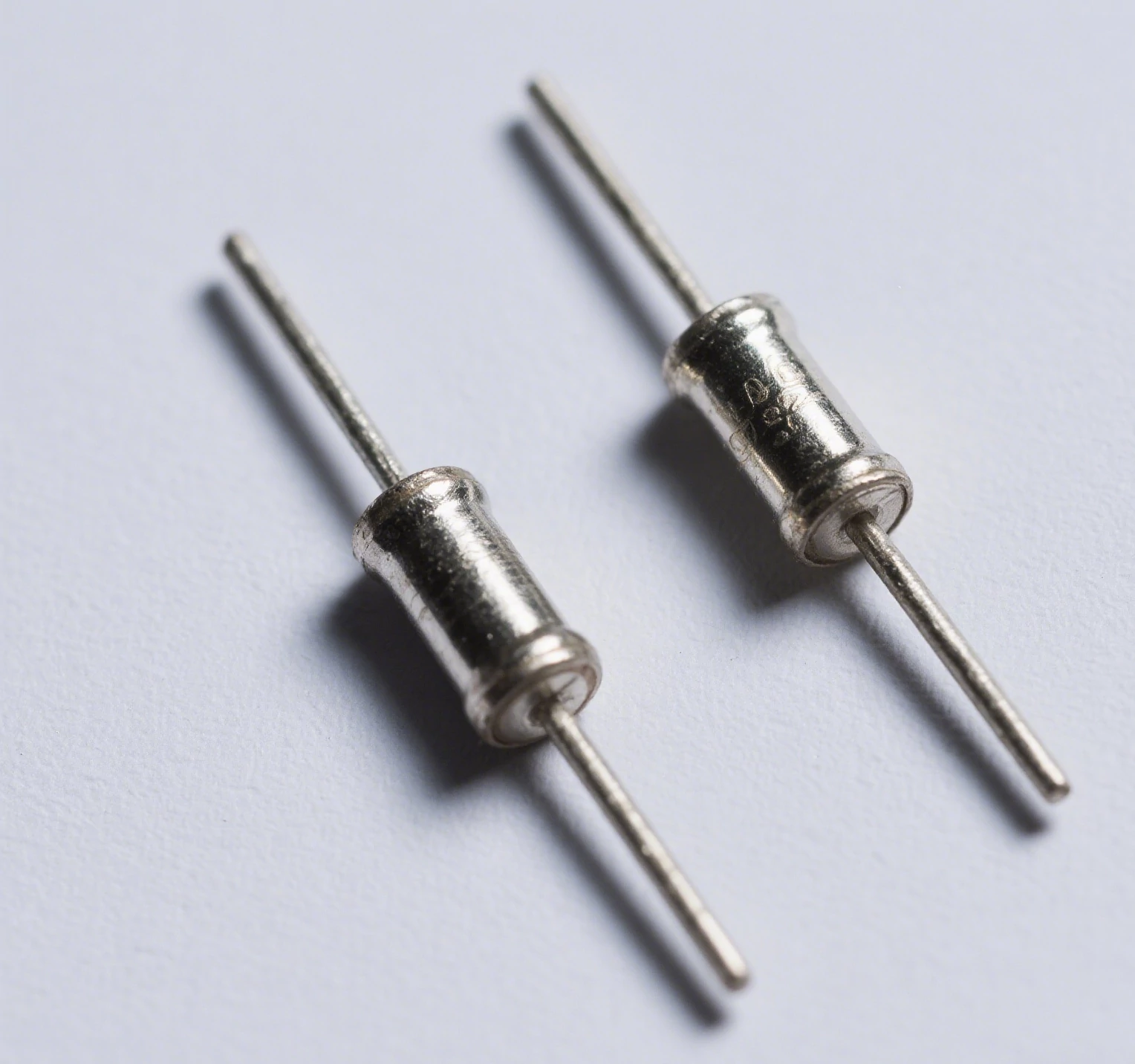

Nickel-plated brass and stainless steel alloys dominate motorcycle BMS connectors, balancing conductivity with mechanical strength. Threaded couplings and self-locking mechanisms prevent disengagement during off-road rides, while spring-loaded contacts maintain electrical continuity under 20G+ vibrations. Such designs are critical for adventure motorcycles and high-impact scenarios.

2.High-Temperature Polymer Housings

Glass-reinforced polyamide (PA66-GF30) and liquid crystal polymer (LCP) housings offer thermal stability up to 150°C, resisting deformation and UV degradation. IP67/IP68-rated seals prevent moisture ingress, ensuring reliability in rainy or humid environments. These lightweight polymers reduce overall battery weight by 30–40%, enhancing portability without compromising durability.

3.EMI-Shielded Configurations

Braided copper shielding combined with ferrite cores minimizes electromagnetic interference from ignition systems or aftermarket electronics. Multi-core shielded cables isolate communication lines (e.g., CAN bus) from power circuits, reducing signal noise by 60–80 dB. This precision ensures accurate voltage and temperature data transmission, preventing overcharging risks.

Key Functional Priorities

Vibration Resistance: Connectors must withstand 50G+ shocks without terminal displacement. Military-grade hyperboloid spring contacts ensure uninterrupted connectivity, even during aggressive off-road riding.

Thermal Management: Phase-change thermal pads or liquid-cooled microchannels dissipate heat from high-current circuits, maintaining optimal operating temperatures (±5°C).

EMI/RFI Protection: Nickel coatings or embedded metal meshes block interference from motors or wireless devices, preserving sensor accuracy for lithium batteries exceeding 600A CCA.

Modularity: Tool-free locking levers and color-coded terminals simplify field repairs. For example, 125°C-rated connectors with audible mating confirmation reduce installation time by 50% in tight spaces.

Emerging Innovations

Graphene-Enhanced Terminals: Graphene-doped copper slashes resistance by 35%, enabling faster charging without overheating. Embedded strain sensors detect micro-cracks, alerting riders via BMS firmware.

Self-Healing Silicone Seals: Microencapsulated agents automatically repair abrasions in gaskets, restoring waterproofing after impacts and extending service life by 3–5 years.

3D-Printed Titanium Lattices: Topology-optimized designs reduce weight by 60% while maintaining crash resistance. Laser-melted airflow channels enable passive cooling in compact battery setups.

Conclusion

Motorcycle lithium battery BMS connectors are engineering marvels, merging ruggedness with precision to withstand mechanical stress and environmental extremes. As electric motorcycles adopt higher-voltage systems (e.g., 800V architectures), next-gen connectors will integrate AI-driven diagnostics and adaptive shielding, evolving from passive parts to proactive safety systems. For riders prioritizing reliability, choosing connectors with MIL-grade vibration resistance, multi-layer shielding, and thermal adaptability isn’t optional—it’s essential for uninterrupted adventures.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!