Key Electrode Winding Process Parameters

main content

Key electrode winding process parameters are pivotal to manufacturing high-quality lithium batteries, directly impacting cell consistency, safety, and energy density. This guide explores three critical parameters—tension gradient design, temperature/humidity control, and dynamic radius compensation—that ensure flawless electrode winding for advanced battery production.

Core Parameters and Technical Insights

1. Tension Gradient Design

Winding tension must balance material stress and structural integrity. For example:

Initial tension: Set to 300gf for separators and 500gf for electrodes to stabilize material feed.

Tension decay: Reduce tension by 510gf per winding cycle to offset stress accumulation. This gradient prevents electrode fractures while maintaining layer adhesion.

Adaptive control: Real-time tension adjustments compensate for material elasticity variations, ensuring uniform winding density.

2. Temperature and Humidity Control

Moisture absorption and thermal instability can degrade separator performance. Critical standards include:

Dew point ≤40°C: Prevents separator moisture retention, avoiding uneven electrolyte wetting.

Humidity tolerance: Maintain relative humidity below 15% in the winding environment.

Thermal regulation: Heat separators to 25–30°C to enhance flexibility and reduce brittleness during high-speed winding.

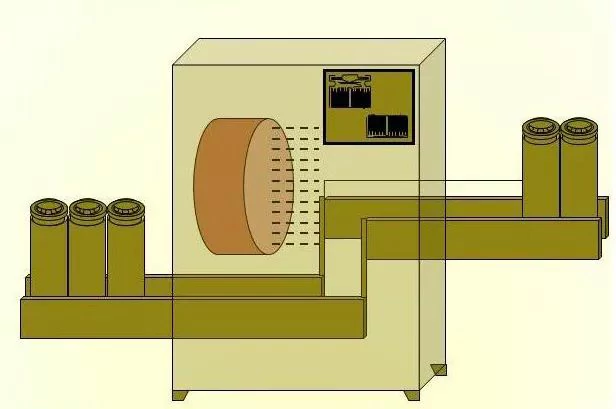

3. Dynamic Radius Compensation

As layers accumulate, the winding radius expands, requiring precise speed adjustments. Key solutions:

Mandrel precision: Limit diameter errors to ±0.02mm to minimize concentricity deviations.

Archimedean spiral model: Calculate real-time radius changes to optimize winding speed.

Speed synchronization: Adjust linear velocity proportionally to radius growth, preventing slippage or layer misalignment.

Technical Advantages

Stress-free electrodes: Tension gradients eliminate wrinkles and fractures.

Consistent electrolyte distribution: Humidity control ensures uniform separator porosity.

Stable core geometry: Dynamic compensation maintains cylindrical/prismatic cell symmetry.

Applications in Modern Battery Production

These parameters are essential for:

High-speed winding: Achieve 25m/s linear velocity without compromising precision.

Thin-film electrodes: Enable ultra-thin (≤6μm) copper/aluminum foil processing.

Solid-state batteries: Support hybrid winding of electrodes and ceramic separators.

Conclusion

Mastering key electrode winding process parameters—tension gradients, environmental controls, and dynamic compensation—is critical for producing reliable, high-energy-density batteries. By integrating adaptive algorithms and precision engineering, manufacturers can meet stringent automotive and industrial standards while driving innovation in energy storage.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!