Insulation Monitoring Unit Materials

main content

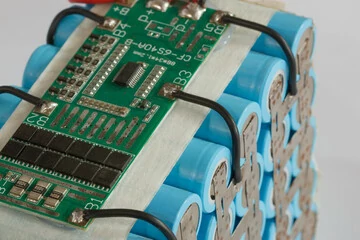

The Insulation Monitoring Unit (IMU) in motorcycle lithium battery BMS relies on specialized materials to ensure electrical isolation, prevent faults, and withstand harsh operating conditions. These materials must balance high dielectric strength, thermal stability, and mechanical resilience to meet safety standards like IEC 61557-8 and ISO 16750-2. Below, we explore the core materials used in IMUs and their functional roles.

Critical Materials for Insulation Monitoring Units

1.High-Performance Polymer Films

Polypropylene (PP) and polyester (PET) films are widely used for insulating battery terminals and sensor circuits. PP films excel in dielectric strength (up to 600 V/mil) and flame retardancy (UL94 V-0), making them ideal for sealing positive connectors and isolating serial ports. PET films, known for dimensional stability, are used in temperature management circuits where heat resistance (up to 150°C) is critical. Both materials are easily molded into 3D shapes for custom applications.

2.Aramid-Based Insulation Papers

Nomex® aramid papers provide exceptional thermal resistance (220°C) and mechanical durability. These materials shield control logic units and voltage sensors from arc faults or overheating. Their low moisture absorption ensures reliable performance in humid environments, a common challenge in motorcycle batteries exposed to rain or condensation.

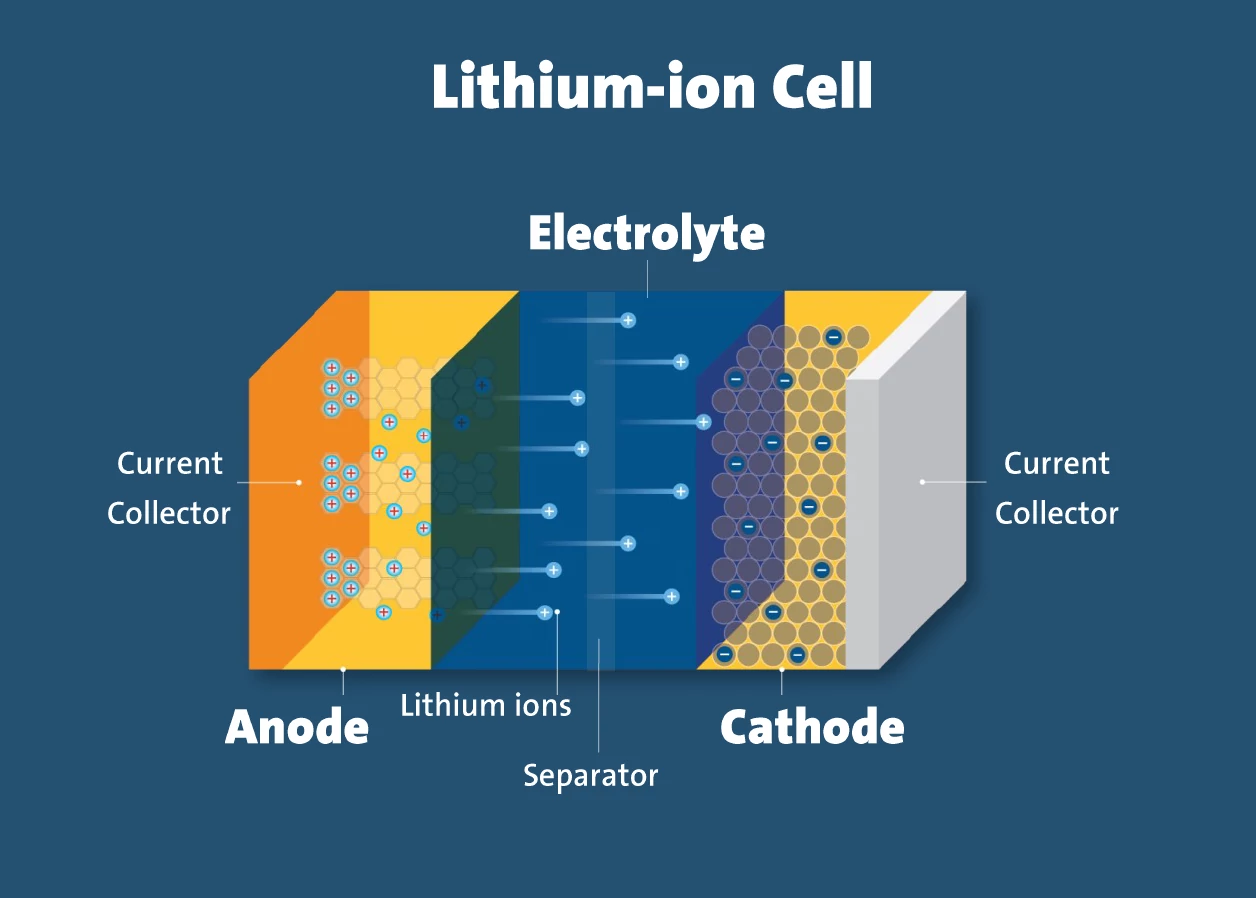

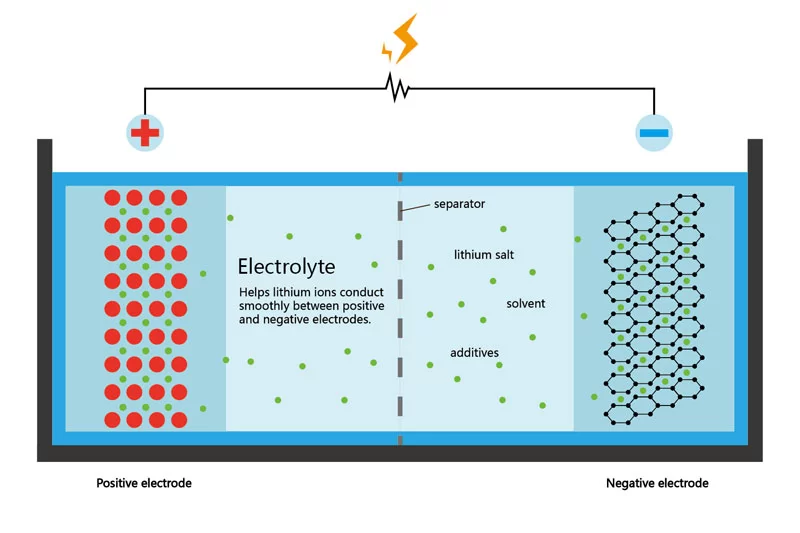

3.Ceramic-Coated Separators

Multi-layer separators with inorganic coatings, such as alumina or silica, prevent thermal shrinkage and short circuits. These coatings enhance dielectric properties while maintaining ionic conductivity. For example, ceramic-bonded polymer separators withstand temperatures exceeding 130°C, ensuring stability during rapid charging or discharge cycles.

4.Flame-Retardant Barriers

3M™ Flame Barrier FRB inorganic papers act as thermal shields between battery cells and IMU components. These materials suppress combustion by releasing water and CO₂ during thermal events, aligning with UL safety standards. They are often integrated into battery casings or edge protection layers to contain thermal runaway risks.

5.Silicone-Based Syntactic Foams

Silicone syntactic foams with hollow glass microspheres combine thermal insulation and vibration damping. These materials protect IMU circuitry from mechanical stress and temperature fluctuations (-20°C to 200°C). Their closed-cell structure prevents moisture ingress, a key factor in preventing insulation degradation.

Material Selection Criteria for IMUs

Dielectric Performance: Materials must resist voltage leakage even at 800V DC systems, common in high-power motorcycle batteries.

Thermal Conductivity: Insulators should dissipate heat efficiently to prevent localized overheating in BMS components.

Environmental Resistance: Resistance to humidity, dust, and chemical exposure ensures longevity in rugged applications.

Flame Retardancy: UL94 V-0 or higher ratings are mandatory to comply with automotive safety protocols.

Manufacturability: Materials must support precision die-cutting, adhesion, and integration with sensors or resistors.

Why Material Quality Matters in IMUs

Motorcycle batteries face vibrations, temperature extremes, and moisture, which accelerate insulation wear. Substandard materials can lead to false fault detection, reduced BMS accuracy, or catastrophic failures like thermal runaway. High-quality insulators, such as polyimide films or syntactic foams, extend battery lifespan by maintaining electrical isolation even under stress. For instance, Nomex®-reinforced modules show 30% lower degradation rates compared to standard materials after 1,000 charge cycles.

Conclusion

Selecting the right insulation monitoring unit materials is pivotal for motorcycle lithium battery safety and efficiency. From flame-retardant barriers to silicone-based foams, each material plays a unique role in preventing faults and ensuring compliance with global standards. By prioritizing durability, thermal stability, and dielectric performance, manufacturers can deliver BMS solutions that withstand the toughest riding conditions while optimizing battery performance.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!