Insulation Monitoring Unit

main content

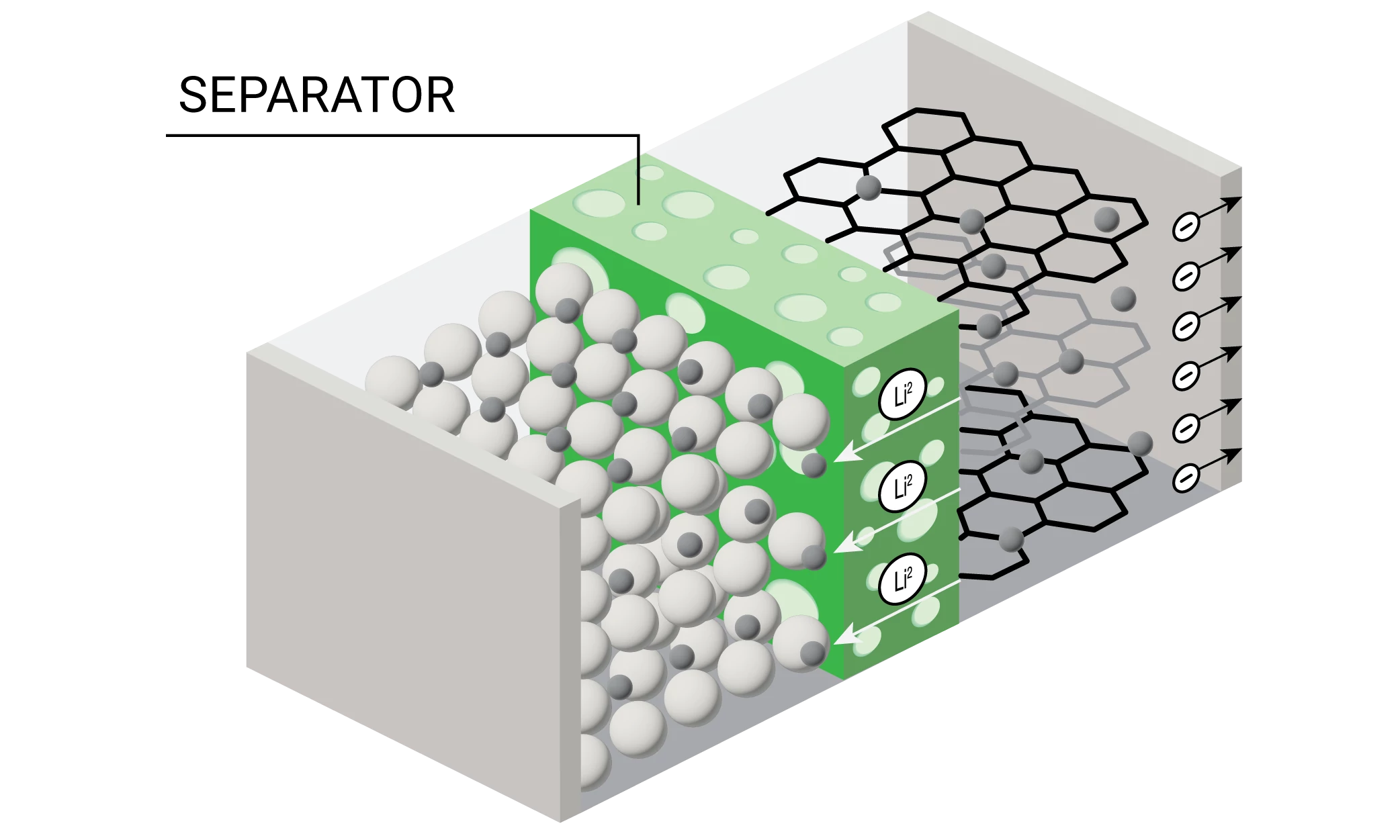

The Insulation Monitoring Unit (IMU) is a critical component of the Battery Management System (BMS) in motorcycle lithium batteries, designed to safeguard against electrical hazards and ensure operational integrity. By continuously evaluating insulation resistance between high-voltage components and the chassis, the IMU prevents risks such as short circuits, leakage currents, and potential fires. This system is vital for compliance with international safety standards and enhancing battery longevity.

Components of the Insulation Monitoring Unit

1.Voltage Sensors: These measure the potential difference between the battery’s positive/negative terminals and the vehicle chassis. Advanced IMUs utilize high-precision sensors to detect even minor deviations in insulation resistance.

2.Reference Resistor Networks: A calibrated resistor network generates a known resistance value, enabling accurate comparison with real-time insulation measurements.

3.Signal Conditioning Circuitry: This module filters noise from raw sensor data, ensuring reliable readings despite environmental interference.

4.Control Logic Unit: Algorithms analyze processed data to determine insulation status. If resistance falls below thresholds (e.g., <500 Ω/V), the unit triggers protective actions.

5.Alert and Shutdown Mechanisms: Audible/visual alarms notify users of insulation degradation, while automatic disconnection of the battery prevents catastrophic failures.

Key Functions of the IMU

1.Real-Time Monitoring: The IMU continuously tracks insulation resistance during battery operation, charging, and idle states. This proactive approach identifies early signs of wear, contamination, or moisture ingress.

2.Fault Detection and Localization: By comparing voltage differentials across terminals, the system pinpoints whether insulation breakdown originates from the positive or negative battery pole.

3.Safety Compliance: The IMU adheres to global standards like ISO 16750-2 and UN ECE R100, which mandate rigorous insulation testing under extreme temperatures and vibrations.

4.Diagnostic Logging: Historical data on insulation performance is stored, aiding technicians in predictive maintenance and root-cause analysis.

Why Insulation Monitoring Matters

In motorcycle applications, lithium batteries face harsh conditions—vibration, dust, and humidity—that degrade insulation over time. A compromised insulation layer can lead to energy loss, reduced battery efficiency, or even thermal runaway. The IMU mitigates these risks by ensuring the electrical isolation between high-voltage components and the vehicle frame remains intact. Moreover, it enhances user confidence by aligning with automotive safety protocols and minimizing downtime through early fault detection.

Conclusion

The Insulation Monitoring Unit is indispensable for modern motorcycle lithium batteries, combining precision engineering with intelligent algorithms to deliver unmatched safety and reliability. By integrating voltage sensing, real-time analysis, and fail-safe mechanisms, it not only protects riders but also extends battery lifespan. For manufacturers and users alike, prioritizing robust insulation monitoring translates to safer rides, regulatory compliance, and optimized performance in demanding environments.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!