Understanding Current Sensing Module Materials in Motorcycle Lithium Battery BMS

main content

The current sensing module materials in a Battery Management System (BMS) play a pivotal role in ensuring precise current measurement, safety, and longevity of motorcycle starting lithium batteries. These materials determine the module’s accuracy, durability, and ability to withstand high-vibration environments. Below, we explore the critical materials used in current sensing modules and their functional significance.

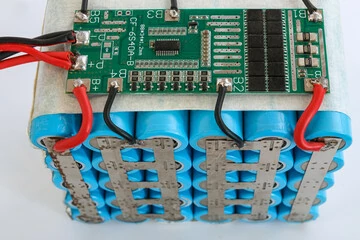

Core Materials and Their Functions

1.Current Sensor ICs: Hall-Effect and Shunt-Based Designs

Hall-effect sensors, such as the MCS1823 or ACS714, rely on semiconductor materials like silicon (Si) or gallium arsenide (GaAs). These ICs use a low-resistance copper conductor (0.6–1.2 mΩ) to minimize energy loss while detecting magnetic field differentials caused by current flow . For shunt-based designs, precision resistors made of manganin or constantan alloys provide stable resistance under varying temperatures, enabling accurate voltage-to-current conversion.

2.Signal Conditioning Circuitry Components

Amplifiers and Filters: Made from silicon-based operational amplifiers (op-amps), these components process raw sensor signals by reducing noise and amplifying weak outputs.

Analog-to-Digital Converters (ADCs): Constructed with CMOS technology, ADCs ensure compatibility with microcontrollers for real-time data analysis .

3.PCB Substrates and Conductive Traces

High-frequency PCB materials like FR4 or polyimide ensure minimal signal distortion. Copper traces with optimized thickness (e.g., 2 oz/ft²) reduce resistive losses, while gold-plated connectors enhance corrosion resistance in humid environments .

4.Protective Encapsulation

Epoxy resins or silicone gels shield sensitive components from moisture, dust, and mechanical stress. These materials maintain electrical insulation and thermal stability across temperatures ranging from -40°C to 150°C .

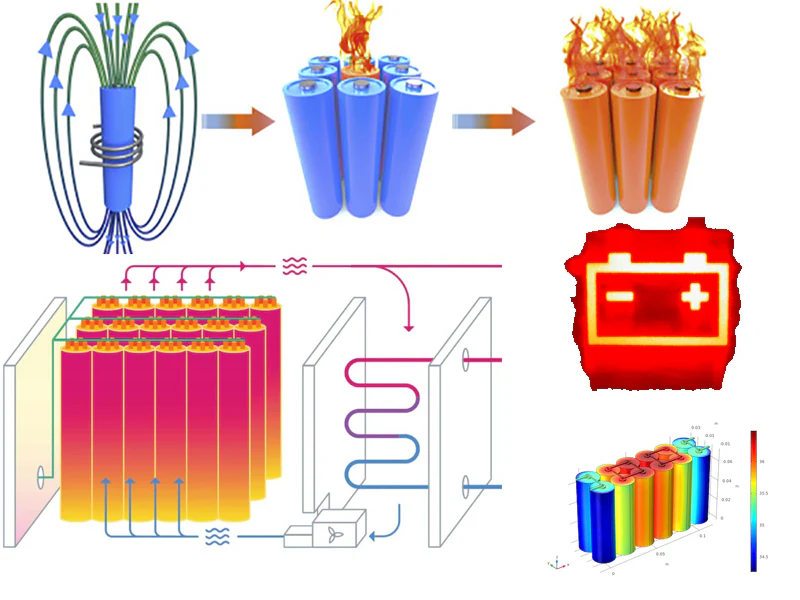

Why Material Selection Matters

Accuracy and Reliability: High-purity semiconductor materials in Hall-effect sensors minimize measurement drift, while low-resistance conductors reduce heat generation during high-current events like engine ignition.

Durability in Harsh Conditions: Robust encapsulation and vibration-resistant PCB substrates ensure consistent performance despite exposure to road shocks and temperature fluctuations.

Energy Efficiency: Advanced materials like manganin resistors and CMOS-based ICs optimize power consumption, extending battery runtime.

Conclusion

The current sensing module materials in motorcycle lithium battery BMS combine precision engineering with ruggedness to meet the demands of high-current applications. From Hall-effect sensor ICs to resilient encapsulation, each material contributes to safety, efficiency, and long-term reliability. For manufacturers and riders, understanding these materials ensures informed decisions for superior battery performance and reduced maintenance costs.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!