Current Sensing Module in BMS

main content

The current sensing module is a cornerstone of Battery Management Systems (BMS) in motorcycle starting lithium batteries. By accurately monitoring and managing electrical currents, this module ensures safe operation, extends battery lifespan, and optimizes performance. Below, we delve into its components, functions, and significance for riders and manufacturers alike.

Components of the Current Sensing Module

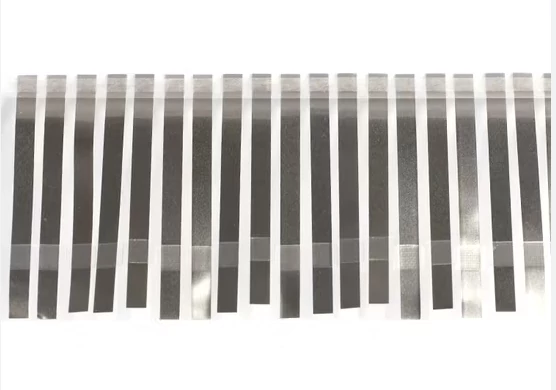

1.Current Sensor ICs

At the core of the module are precision current sensor ICs, such as Hall-effect sensors (e.g., MCS1823). These ICs detect both AC and DC currents flowing through the battery. Using magnetic field differentials, they convert current variations into measurable voltage signals. Their low resistance minimizes energy loss while maintaining high accuracy.

2.Signal Conditioning Circuitry

Raw data from sensors is processed by signal conditioning circuits. These components filter noise, amplify weak signals, and calibrate outputs to ensure reliable measurements. Advanced systems integrate analog-to-digital converters (ADCs) for seamless compatibility with microcontrollers.

3.Communication Interfaces

To relay data to the BMS, the module employs interfaces like CAN Bus or SPI. These protocols enable real-time communication with other subsystems, such as motor controllers or chargers, to adjust operations dynamically.

Key Functions of the Current Sensing Module

1.Real-Time Current Monitoring

Continuously tracking charge/discharge currents allows the BMS to calculate the battery’s State of Charge (SoC) and State of Health (SoH). This data is critical for preventing overcharging or deep discharging, which can irreversibly damage cells.

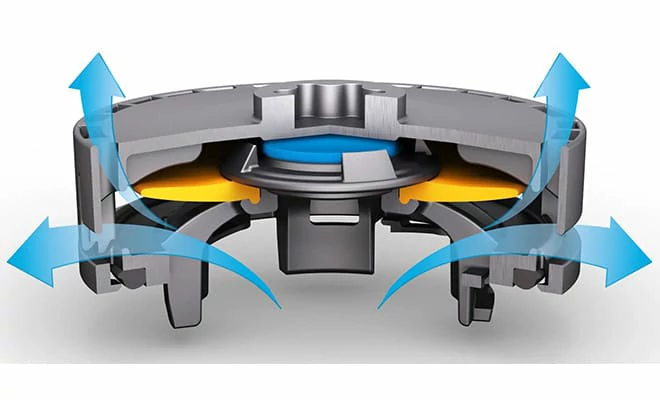

2.Overcurrent and Short-Circuit Protection

By detecting abrupt current spikes, the module triggers protective measures. For instance, it disconnects the load via MOSFETs or requests torque reduction in motor controllers, safeguarding against thermal runaway or circuit damage.

3.Energy Efficiency Optimization

Precise current measurements enable the BMS to balance power distribution. This ensures the battery operates within its optimal range, minimizing energy waste and maximizing runtime.

4.Fault Diagnosis and Predictive Maintenance

Abnormal current patterns, such as gradual increases in internal resistance, signal potential cell degradation. Early detection allows for proactive maintenance, reducing downtime and repair costs.

Why It Matters for Motorcycle Lithium Batteries

In high-vibration environments like motorcycles, reliable current sensing is non-negotiable. A robust module ensures consistent performance during ignition surges, regenerative braking, or extreme temperature fluctuations. Furthermore, its integration with BMS algorithms enhances safety—critical for preventing hazards like overheating or cell failure.

Conclusion

The current sensing module is the unsung hero of lithium battery BMS, combining precision engineering with intelligent data processing. By understanding its components and functions, manufacturers and riders alike can appreciate its role in delivering power, safety, and longevity. For motorcycle applications, investing in advanced current sensing technology translates to smoother rides and fewer maintenance headaches.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!