Battery Management System MCU

main content

The Battery Management System (BMS) Main Control Unit (MCU) serves as the intelligent core of lithium motorcycle starter batteries, orchestrating safety, efficiency, and longevity. By integrating advanced algorithms and real-time monitoring, the MCU ensures optimal performance across diverse conditions. Let’s delve into its composition and key functionalities.

Core Components of the BMS MCU

1.High-Performance Processor

The MCU relies on a robust microcontroller to execute complex calculations. These include state-of-charge (SOC) and state-of-health (SOH) estimations, critical for predicting battery runtime and lifespan. Modern MCUs often feature low-power designs to minimize energy consumption while maintaining precision.

2.Integrated Memory Modules

Flash and RAM modules store firmware, cell models, and operational data. This allows the MCU to adapt to dynamic conditions, such as temperature fluctuations or load changes, ensuring consistent performance.

3.Communication Interfaces

CAN bus, UART, or I2C protocols enable seamless interaction with external systems like fuel gauges, analog front-ends (AFEs), and vehicle controllers. For instance, CAN bus integration supports real-time data exchange with chargers and IoT-enabled diagnostics.

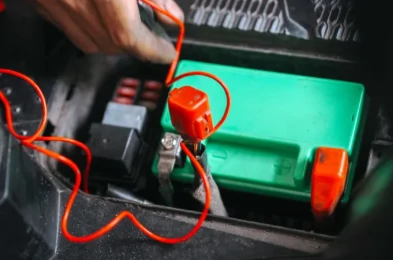

4.Protection Circuitry Drivers

Dedicated drivers control high-side or low-side MOSFETs to disconnect the battery during faults. This hardware-based protection reacts faster than software-driven solutions, preventing overcurrent, short circuits, or thermal runaway.

5.ADC and Sensor Inputs

Analog-to-digital converters (ADCs) process voltage, current, and temperature signals from sensors. Synchronized voltage-current readings enhance resistance calculations, improving SOC accuracy even under rapid discharge cycles.

Key Functions of the BMS MCU

1.Real-Time Monitoring and Analysis

The MCU continuously tracks cell voltages, temperatures, and currents. By comparing these values against predefined thresholds, it detects anomalies like overcharging or deep discharge, triggering immediate protective actions.

2.Advanced Algorithm Execution

Sophisticated algorithms analyze battery behavior using cell-specific models. These models, derived from extensive testing under varied conditions, enable precise SOC/SOH predictions and adaptive balancing strategies.

3.Fault Management and Safety Protocols

Prioritizing safety, the MCU autonomously activates fail-safes—such as disconnecting loads or chargers—during critical faults. Dual-layer protection (hardware + firmware) ensures redundancy, complying with automotive safety standards.

4.Communication and System Integration

The MCU bridges the battery pack with external systems. For example, Bluetooth-enabled MCUs allow users to monitor battery health via mobile apps, while CAN interfaces ensure compatibility with vehicle control networks.

5.Energy Optimization

By dynamically adjusting charge/discharge rates and balancing cell voltages, the MCU maximizes energy utilization. This extends battery life and enhances cold-cranking performance, crucial for motorcycle starter applications.

Conclusion

The Battery Management System MCU is indispensable for modern lithium motorcycle batteries. Combining cutting-edge hardware with intelligent software, it safeguards against risks, optimizes energy use, and delivers reliable power—even in extreme environments. For riders and manufacturers alike, investing in a robust MCU translates to safer rides, longer battery life, and reduced maintenance costs.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!