Components of BMS

main content

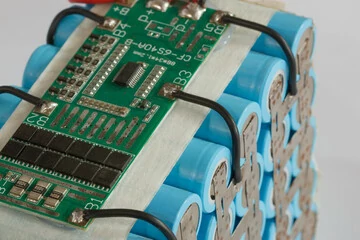

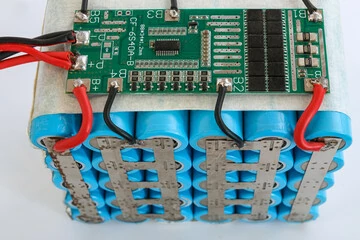

In the application of motorcycle start-up lithium battery, Battery Management system (BMS) is the core component to ensure the safe and efficient operation of the battery. By accurately monitoring and managing the parameters of the battery, BMS can extend battery life, improve performance, and ensure safety. The following are the main components of BMS and their functions:

The main control module is the brain of the BMS, which is responsible for receiving and processing data from each monitoring unit and making decisions according to preset algorithms and logic. For example, STM32F103C8T6 is a commonly used master control chip, which can realize single voltage and overall voltage detection, over-charge and over-discharge alarm and protection functions. It also supports charging and discharging current detection, equalization function and multiple communication methods such as TTL, CAN and Bluetooth.

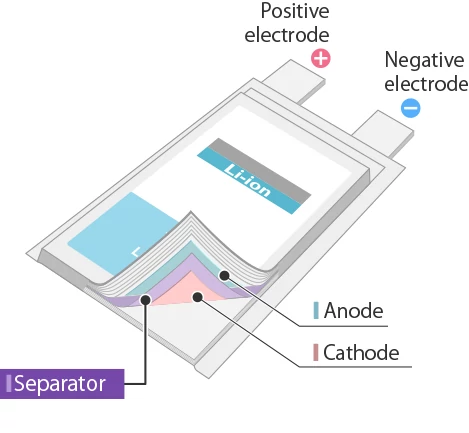

The voltage monitoring unit is used to monitor the voltage of each battery cell in real time to ensure that it is within a safe range. Through the high-precision voltage measurement chip, the precise collection of each single battery voltage can be realized, which provides key data for the subsequent battery management strategy. Abnormal voltage can be an early indication of battery cell failure, so voltage monitoring is a very important function in BMS.

The current detection module monitors the charging and discharging current of the battery pack in real time through the Hall current sensor or shunt. It is able to calculate the charge and discharge capacity of the battery and accurately assess the remaining capacity of the battery. The current detection module can also set a variety of current limits, such as continuous discharge current, continuous charge current, peak discharge current, and peak charge current.

The temperature sensor network is used to monitor the temperature of the battery pack and its surrounding environment to prevent the battery from being damaged by overheating or overheating. The temperature monitoring range is usually -40 ° C to 125 ° C, and the accuracy can reach ±1 ° C. Temperature data is essential for battery charge and discharge control and safety protection.

The balance management module balances the power of each single battery in the battery pack by active or passive balancing. Active equalization techniques include capacitor equalization, inductance equalization and DC-DC transformation equalization, etc., while passive equalization consumes excess power through parallel resistors. Balanced management can prolong the life of the battery pack and improve the overall performance.

The protection circuit is the safety line of the BMS and is responsible for cutting off the circuit in case of abnormal conditions in the battery. For example, when the battery voltage is too high or too low, the current is too large, or a short circuit occurs, the protection circuit will quickly cut off the MOSFET switch to prevent battery damage.

The communication interface module is used to realize the data exchange between BMS and other systems. Common communication methods include TTL, CAN, I2C, and Bluetooth. Through the communication interface, the BMS can send the status information of the battery to the Electronic Control Unit (ECU) of the motorcycle, and also communicate with the charger to control the charging process.

The insulation monitoring unit is used to detect the insulation resistance between the battery pack and the vehicle chassis. When the insulation resistance is lower than the set value, there may be a risk of leakage, and the BMS will issue an alarm in time and take measures to ensure safe use.

The power management unit is responsible for providing a stable power supply to the BMS. It usually includes DC-DC buck converters, LDO linear regulators, etc., capable of converting the battery voltage to the low voltage power required by the system.

The safety isolation device is used to prevent the interference of the high voltage circuit to the low voltage control circuit. For example, digital isolation devices can ensure stable transmission of communication signals in high-voltage environments.

The structural encapsulation material is used to protect the electronic components of the BMS from damage caused by the external environment. A good package design can improve the reliability and durability of BMS.

The algorithm and software layer is the intelligent core of the BMS, which is responsible for processing monitoring data, enforcing protection policies, and optimizing the charging and discharging process of the battery. Through sophisticated algorithms, the BMS can accurately estimate the remaining charge (SOC) and state of health (SOH) of the battery and adjust the charging and discharging strategy based on these data.

Conclusion

The Battery Management System (BMS) of the motorcycle starting lithium battery is composed of several key parts, each of which plays an indispensable role. From the main control module to various monitoring units, to protection circuits and communication interfaces, BMS ensures the safe and efficient operation of lithium batteries through accurate monitoring and intelligent management. With the continuous progress of technology, the performance and function of BMS will continue to improve, providing a more reliable guarantee for the application of motorcycle start-up lithium battery.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!